Hey Guys,

As a lot of you seem to be interested in the modification I did to my Crown regulator to prevent creep and improve the settling time, I decided to take my Crown apart to make a tutorial.

disclaimer: Don't do this mod when you are not feeling comfortable doing it, I can't estimate someone else's technical skills, and you need to work very clean and precise. There is a risk of messing up the parts.

Tools needed:

Metric allen keys of good quality, sizes 2mm, 2.5mm, 3mm, 4mm and 5mm

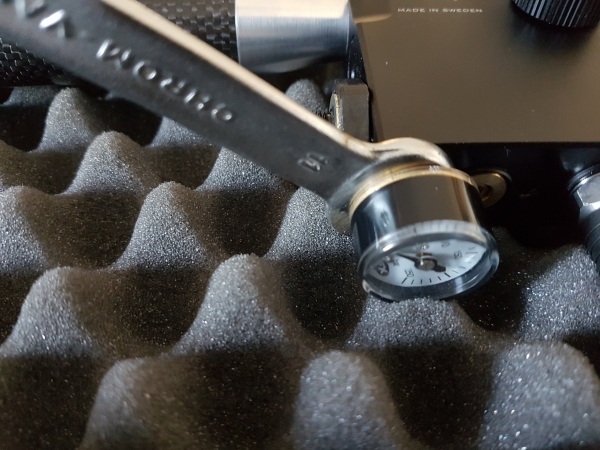

Size 11mm thin spanner (I had to grind one down to fit the narrow space between gauge and action.

Artery clamp

Silicon grease.

Step 1, remove the safety lever with a 2.5mm allen key:

Step 2, remove the power adjuster wheel with a 2mm allen key (be careful not to loose the 2 ball bearings underneath the adjuster wheel)

Step3, remove the stock (3mm and 4mm allen key):

Step 4, remove the stock

Step 5, remove the bottle

Step 6, If the reg. isn't degassed yet, (see gauge) dry fire on lowest power setting of both power wheels until the regulator bleeds all air.

Step 7, remove gauge (bottle pressure) 11mm spanner.

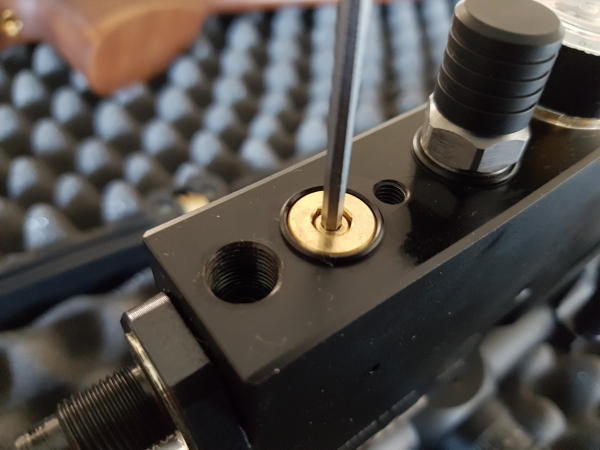

Step 8, remove regulator adjustment screw (2.5mm allen key)

Step 9, remove the regulator retention screw (5mm allen key)

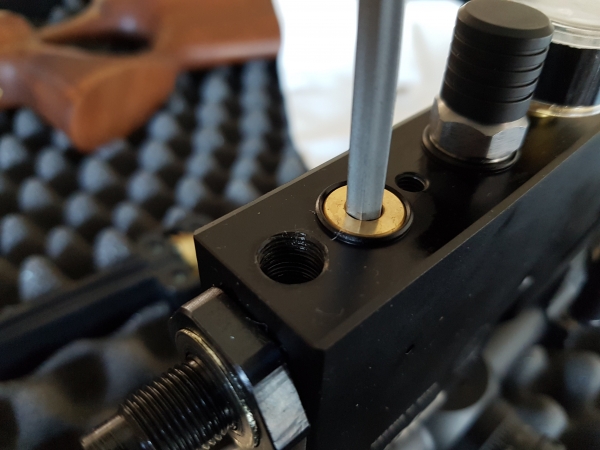

Step 10, remove the regulator piston (artery clamp) and make sure not to damage it, as it is Delrin (soft). I've put some tape around the noses of the clamp to prevent it from damaging.

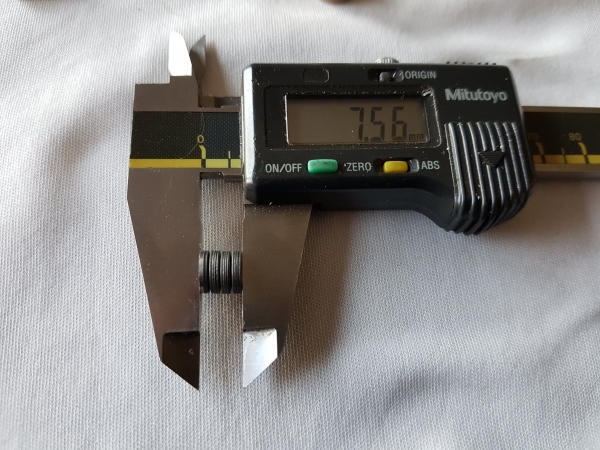

Step 11, stack the belleville washers in a different way

original setup, 16 bv washers stacked like this: ()()()()()()()()

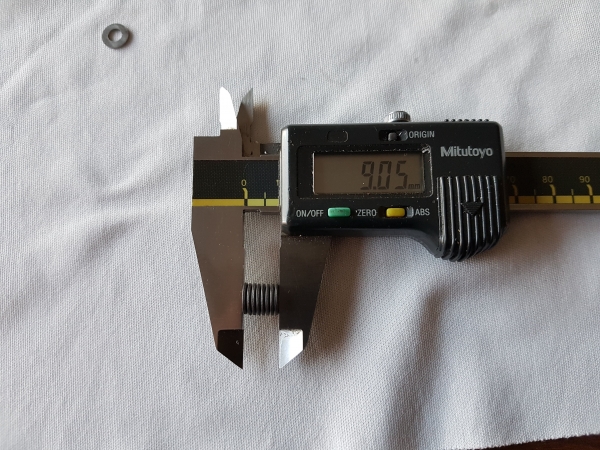

my setup: |))(())(())(()) I started at the piston side with a drilled out and O.D. turned down m3 washer to prevent the sharp edges of the belleville washers from digging in the soft Delrin surface. Any fitting washer will do the trick, as long it is flat and fits the hole.

The belleville washers are twice as stiff in this config, and the travel has decreased a lot.

Note that my stack is shorter, with a longer stack the regulator piston could not reach the adjuster screw anymore, so the reg. could not be adjusted.

Step 12, assemble in reverse order, and adjust reg pressure as specified by FX (but now you can run a higher reg pressure than FX's recommended 150bar.)

Note: all regulator parts should be assembled "finger tight", the o rings will seal the parts, not the threads. Rather be on the loose side than too tight. Especially the regulator adjustment screw.

As a bonus, my way of adjusting down without degassing:

When you dryfire a shot, the gauge of the regulator gauge takes a big dip in pressure.

This dip normally takes about 1 second before the pressure settles again.

In this second, the regulator piston is not making contact with the adjuster screw.

So, within this second, I immediately turn in the reg adjuster screw about 1/8th of a turn.

Now the regulated pressure will be down, and can be worked up to the desired pressure again.

Works perfect and saves a lot of hassle (degassing)

Good luck, Gijs

As a lot of you seem to be interested in the modification I did to my Crown regulator to prevent creep and improve the settling time, I decided to take my Crown apart to make a tutorial.

disclaimer: Don't do this mod when you are not feeling comfortable doing it, I can't estimate someone else's technical skills, and you need to work very clean and precise. There is a risk of messing up the parts.

Tools needed:

Metric allen keys of good quality, sizes 2mm, 2.5mm, 3mm, 4mm and 5mm

Size 11mm thin spanner (I had to grind one down to fit the narrow space between gauge and action.

Artery clamp

Silicon grease.

Step 1, remove the safety lever with a 2.5mm allen key:

Step 2, remove the power adjuster wheel with a 2mm allen key (be careful not to loose the 2 ball bearings underneath the adjuster wheel)

Step3, remove the stock (3mm and 4mm allen key):

Step 4, remove the stock

Step 5, remove the bottle

Step 6, If the reg. isn't degassed yet, (see gauge) dry fire on lowest power setting of both power wheels until the regulator bleeds all air.

Step 7, remove gauge (bottle pressure) 11mm spanner.

Step 8, remove regulator adjustment screw (2.5mm allen key)

Step 9, remove the regulator retention screw (5mm allen key)

Step 10, remove the regulator piston (artery clamp) and make sure not to damage it, as it is Delrin (soft). I've put some tape around the noses of the clamp to prevent it from damaging.

Step 11, stack the belleville washers in a different way

original setup, 16 bv washers stacked like this: ()()()()()()()()

my setup: |))(())(())(()) I started at the piston side with a drilled out and O.D. turned down m3 washer to prevent the sharp edges of the belleville washers from digging in the soft Delrin surface. Any fitting washer will do the trick, as long it is flat and fits the hole.

The belleville washers are twice as stiff in this config, and the travel has decreased a lot.

Note that my stack is shorter, with a longer stack the regulator piston could not reach the adjuster screw anymore, so the reg. could not be adjusted.

Step 12, assemble in reverse order, and adjust reg pressure as specified by FX (but now you can run a higher reg pressure than FX's recommended 150bar.)

Note: all regulator parts should be assembled "finger tight", the o rings will seal the parts, not the threads. Rather be on the loose side than too tight. Especially the regulator adjustment screw.

As a bonus, my way of adjusting down without degassing:

When you dryfire a shot, the gauge of the regulator gauge takes a big dip in pressure.

This dip normally takes about 1 second before the pressure settles again.

In this second, the regulator piston is not making contact with the adjuster screw.

So, within this second, I immediately turn in the reg adjuster screw about 1/8th of a turn.

Now the regulated pressure will be down, and can be worked up to the desired pressure again.

Works perfect and saves a lot of hassle (degassing)

Good luck, Gijs