Almost two years ago there was a topic started on someone inquiring about home made, DIY, pellet traps thst one could easily muster up parts and have somewhat of a safe projectile catcher that a target could be attached to. Rubber mulch was the media that was highly recommended on this topic, and sure enough different members started posting pics of their home brew set ups.

All the pics sparked an idea. Now mind you, I already own two pellet traps, steel structure snd backing media is the tried and true duct seal, but after a couple of years using these 10” x 10” steel boxes filled with 7 lbs of duct seal, the idea of the lighter media in rubber mulch appealed to me. Plus, one of my goals is to one day try my hand at one of(or both) of the annual benchrest competitions and I already know that’s a lot of practicing. Out to a 100 yards, I couldn’t see myself hauling around these heavy pellet traps, and say, I wanted to shoot closer the idea of moving the heavy trap closer or farther just put me off. Then, the worst part comes at the end of the shooting session, all the gear including those heavy steel boxes a 100 yards away would have to be put away.

so in my mind, it had to either be easily portable, or be able to withstand the weather and just be left outside. These two pluses alone means I’ll set up to shoot more often, as it would be less work to set up and clean up.

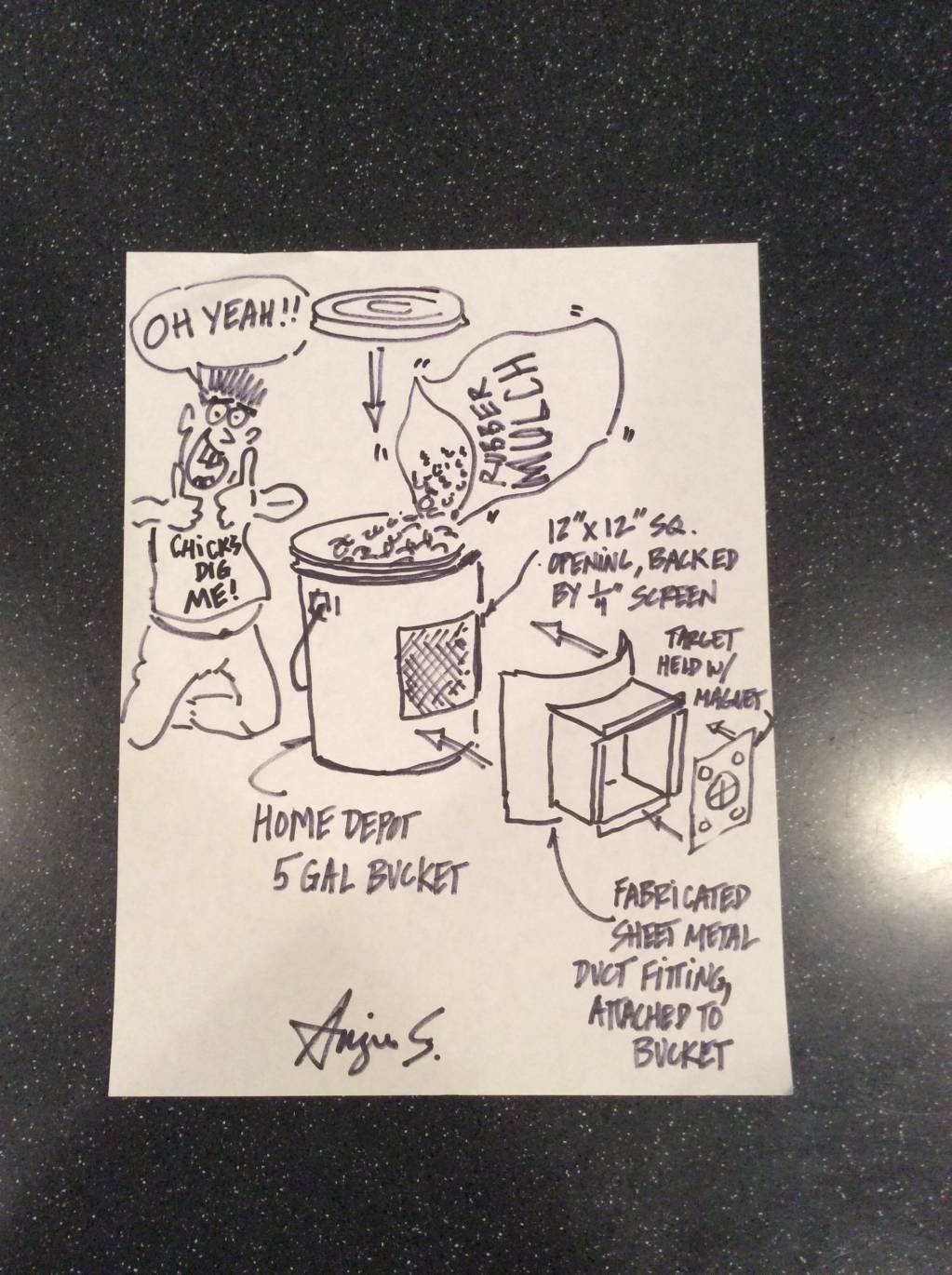

So I posted this cartoon plan of mine on that very thread, the DIY one, and said one day I’m going to build these-

I have had all the parts to make these for awhile, minus the rubber mulch. My goal was to build 5 of these so I could set these up at 12-18” off the ground, in 10 yard increments, starting from 60 yards all the way to 100.

So the first prototype was built today-

All the pics sparked an idea. Now mind you, I already own two pellet traps, steel structure snd backing media is the tried and true duct seal, but after a couple of years using these 10” x 10” steel boxes filled with 7 lbs of duct seal, the idea of the lighter media in rubber mulch appealed to me. Plus, one of my goals is to one day try my hand at one of(or both) of the annual benchrest competitions and I already know that’s a lot of practicing. Out to a 100 yards, I couldn’t see myself hauling around these heavy pellet traps, and say, I wanted to shoot closer the idea of moving the heavy trap closer or farther just put me off. Then, the worst part comes at the end of the shooting session, all the gear including those heavy steel boxes a 100 yards away would have to be put away.

so in my mind, it had to either be easily portable, or be able to withstand the weather and just be left outside. These two pluses alone means I’ll set up to shoot more often, as it would be less work to set up and clean up.

So I posted this cartoon plan of mine on that very thread, the DIY one, and said one day I’m going to build these-

I have had all the parts to make these for awhile, minus the rubber mulch. My goal was to build 5 of these so I could set these up at 12-18” off the ground, in 10 yard increments, starting from 60 yards all the way to 100.

So the first prototype was built today-