I am having an issue with the three magazines that I have. I'm using normal 25 Cal JSB Kings, and when I go to load the magazine, anywhere from three to five of the pellets are crushing the o-ring against the front of the pellet and the wall of the magazine as I push them in and the pellets are getting stuck. To give you a better idea of the issue, instead of the pellet riding over and moving past the two o-rings, the pellet is moving past the first o-ring and crushing the second o-ring against the wall of the magazine in front of the pellet. This "obstruction" of sorts, stops the pellet from advancing and I've had to use accessive force with a screwdriver in the reverse direction to get the pellet out. I have tried to troubleshoot the issue by using Teflon lubricant on the o-ring, and that helps the pellet get past the initial o-ring very quickly now, though many still get stuck on the second o-ring and have the same pinching effect. I have tried to remove one of the o-rings but using a single o-ring show to have the same issue. This issue is happening with all three magazines, and the problem will occur with random pellets within the loading phase. Not sure if these magazines are defective or the o-ring channel is cut too deep and the pellet is squeezing the o-ring against the edge of the magazine instead of riding over it. Has anyone else experienced this issue? Maybe a different type of o-ring could be used?

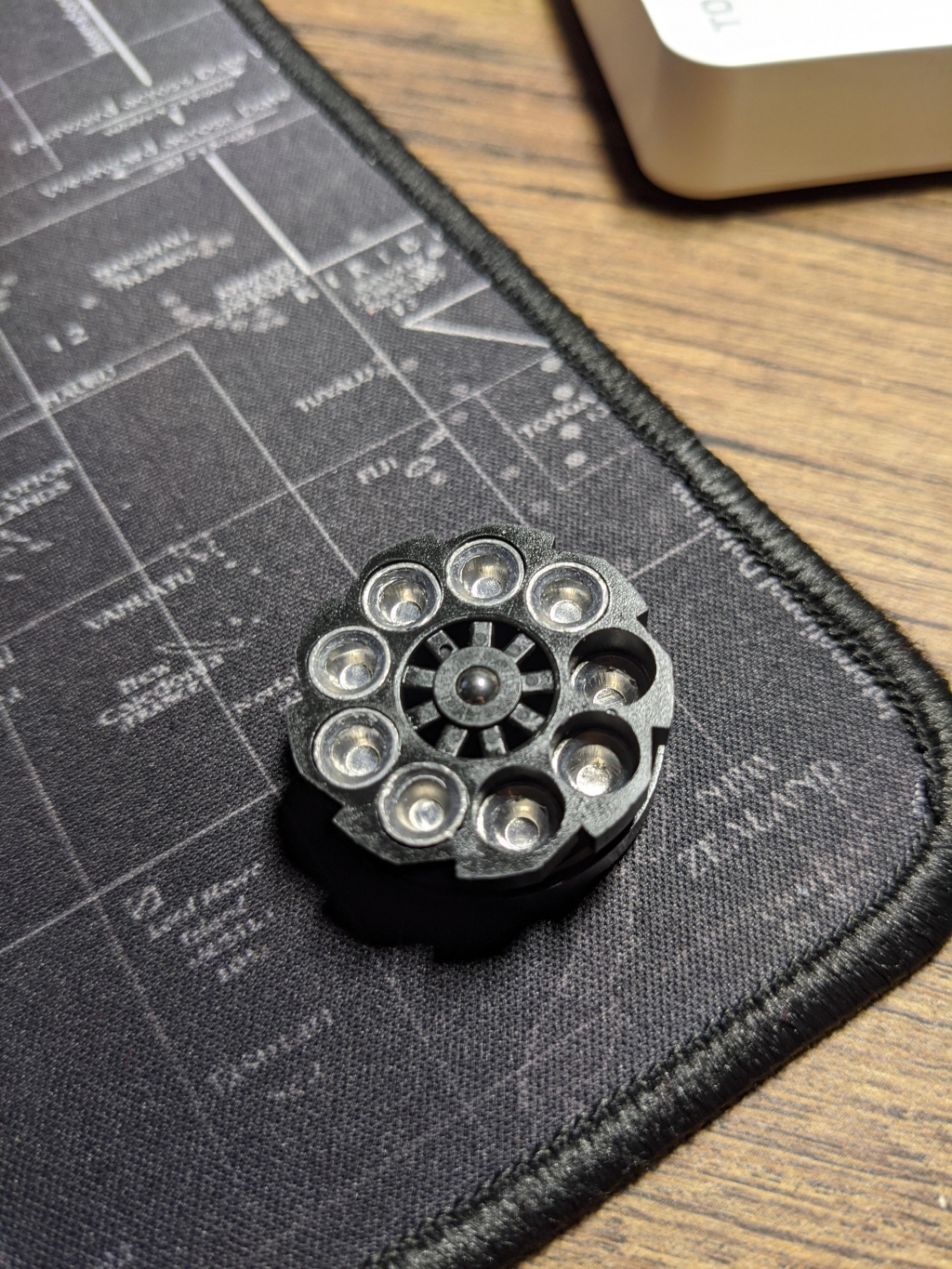

You can see in this picture that I was able to get three to seat properly and move past the two o-rings, the six that are not seated as far are stuck on the last o-ring as it pinches it against the wall:

If this picture, you can see that the pellet is visible through the double o-ring as it is pinched and not visible on the pellet that has been seated properly, the two red circles on the left highlight the pellets that have been seated properly, the two circles on the right show the pinched o-rings:

In this final picture, you can see that the o-ring is stopping the pellet from advancing any further into the magazine. These were not simply pressed in, I am using a hex wrench to seat the pellets and once I experience resistance I stopped. This just so happened to be six in a row but often it's random when it pinches the o-ring against the wall of the magazine:

You can see in this picture that I was able to get three to seat properly and move past the two o-rings, the six that are not seated as far are stuck on the last o-ring as it pinches it against the wall:

If this picture, you can see that the pellet is visible through the double o-ring as it is pinched and not visible on the pellet that has been seated properly, the two red circles on the left highlight the pellets that have been seated properly, the two circles on the right show the pinched o-rings:

In this final picture, you can see that the o-ring is stopping the pellet from advancing any further into the magazine. These were not simply pressed in, I am using a hex wrench to seat the pellets and once I experience resistance I stopped. This just so happened to be six in a row but often it's random when it pinches the o-ring against the wall of the magazine: