If your wife, daughter or girlfriend have any spare hair bands, I'm sure they'll do the trick.

Upvote 0

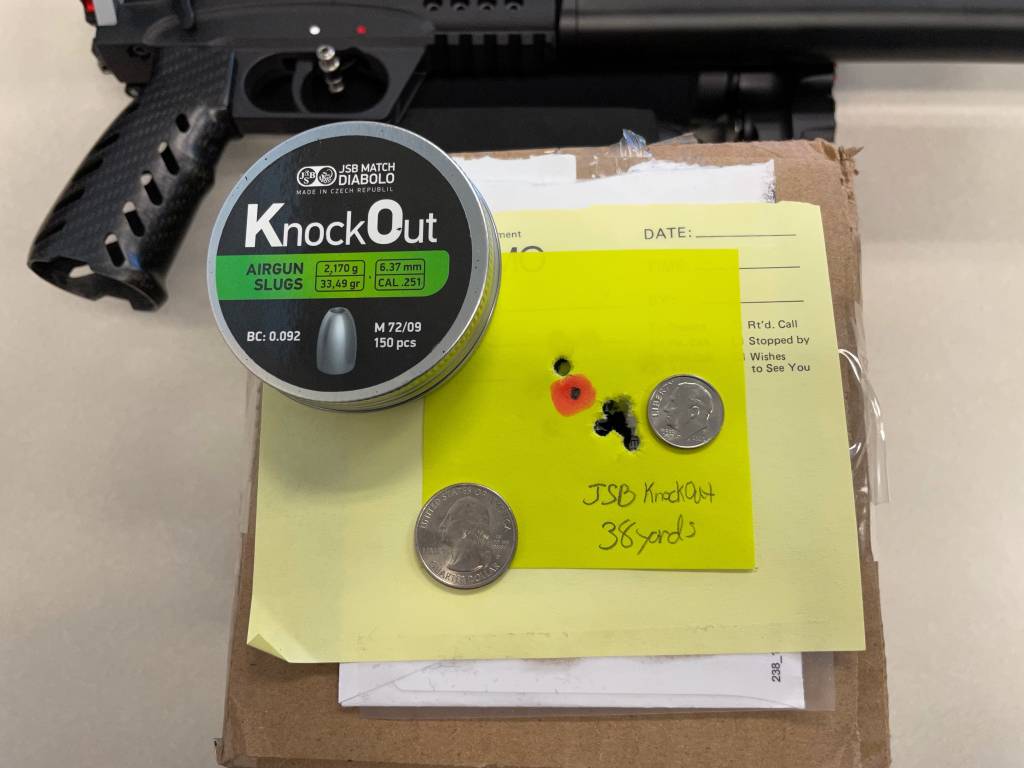

..But I was extremely surprised that the JSB KnockOuts .33.49gr at this low speed of around 800fps are very accurate at 38 yards in my L2.

..But I was extremely surprised that the JSB KnockOuts .33.49gr at this low speed of around 800fps are very accurate at 38 yards in my L2.

Ed also tested those:

https://www.youtube.com/watch?v=bFBjYkca1Jg

If you have to plate a part for rust you already made it out of the wrong material . And I agree alot of these manufacturer's use soft crappy aluminum and the anodizing overseas leaves ALOT be desired for sure and apparently their nickel plating also!

If you have to plate a part for rust you already made it out of the wrong material . And I agree alot of these manufacturer's use soft crappy aluminum and the anodizing overseas leaves ALOT be desired for sure and apparently their nickel plating also!

Such a sweeping statement is simply not true. Coating a part does not mean it's been made of the wrong material. I know a lot of engineers that would disagree with you.

If you have to plate a part for rust you already made it out of the wrong material . And I agree alot of these manufacturer's use soft crappy aluminum and the anodizing overseas leaves ALOT be desired for sure and apparently their nickel plating also!

Such a sweeping statement is simply not true. Coating a part does not mean it's been made of the wrong material. I know a lot of engineers that would disagree with you.

I have worked with engineers my whole life and they DO NOT KNOW EVERYTHING that should be used in the real world... Page 119 I believe is where Ed said the rusted so they played them!

If you have to plate a part for rust you already made it out of the wrong material . And I agree alot of these manufacturer's use soft crappy aluminum and the anodizing overseas leaves ALOT be desired for sure and apparently their nickel plating also!

Such a sweeping statement is simply not true. Coating a part does not mean it's been made of the wrong material. I know a lot of engineers that would disagree with you.

I have worked with engineers my whole life and they DO NOT KNOW EVERYTHING that should be used in the real world... Page 119 I believe is where Ed said the rusted so they played them!

I have been an engineer for most of my adult life. We certainly don't know everything (and usually it's only the shiny new ones that think they do...), but there is also not always a "right" answer. We'd all love the parts on our guns to be lightweight, super-rigid, without being brittle, corrosion and chemical proof, abrasion-resistant, non-galling, dimensionally stable across all temperatures, lubricous (except when they shouldn't be), and of course, dirt cheap. But... real life doesn't work that way so we trade one attribute, say abrasion resistance, for another, say corrosion resistance - all with cost considerations. And, of course, sometimes we choose poorly, and other times we're wrong - we are, after all, partly human. But we sure do hear from a lot of armchair experts who don't even know what the question was.

GsT

If you have to plate a part for rust you already made it out of the wrong material . And I agree alot of these manufacturer's use soft crappy aluminum and the anodizing overseas leaves ALOT be desired for sure and apparently their nickel plating also!

Such a sweeping statement is simply not true. Coating a part does not mean it's been made of the wrong material. I know a lot of engineers that would disagree with you.

I have worked with engineers my whole life and they DO NOT KNOW EVERYTHING that should be used in the real world... Page 119 I believe is where Ed said the rusted so they played them!

I have been an engineer for most of my adult life. We certainly don't know everything (and usually it's only the shiny new ones that think they do...), but there is also not always a "right" answer. We'd all love the parts on our guns to be lightweight, super-rigid, without being brittle, corrosion and chemical proof, abrasion-resistant, non-galling, dimensionally stable across all temperatures, lubricous (except when they shouldn't be), and of course, dirt cheap. But... real life doesn't work that way so we trade one attribute, say abrasion resistance, for another, say corrosion resistance - all with cost considerations. And, of course, sometimes we choose poorly, and other times we're wrong - we are, after all, partly human. But we sure do hear from a lot of armchair experts who don't even know what the question was.

GsT

Exactly. One of the biggest things I've learned through my engineering career so far is that we don't know everything. I just can't stand sweeping statements like the bolded one so I had to say something.

Just posted speed loader design files in .177, .22, .25 and .30 cal, if you own a 3D printer, be kind and print some for you mates

https://www.airgunnation.com/topic/leshiy-2-3d-print/?view=all#post-1002489

Can anybody say definitively what the twist rates are on the LW and Alpha barrels?

I'm looking specifically at .22 LW, .25 Alpha and .30 Alpha.

Yesterday i recived the insert from raxim777, who is a very nice guy, very profesional, really a big different, back yard-frienly now my L2.