Hi, I write this feeling a little stupid. I have had my dreamline close to a year, and it lost all its air overnight, after no problems. So I thought I would give it a clean and check the obvious, like fill valve, tank, and reg O rings. I was looking at the trigger, and it had what looked like very fine silvery filings in, and around the hammer. So I took hammer/trigger out. It appears to me that the rough spring ends have possibly cut all these filings, as where the spring sits in the hammer adjuster, (Dreampup) one side has had black finish worn off it. So I polished the spring ends, and thought I would give everything that touches a light clean and smooth off. I didn't touch the sears, other than clean them.

So I put it all back together, and the small sear that latches onto the ridge around the hammer just won't engage. It slides past, but won't "hook up", and so the gun won't cock. It is the right way around too.

So in polishing the hammer, have I taken a micro edge off the hammer engagement ridge part? I didn't do anything more than hold 600 grit wet and dry onto this ridge and twirl with my fingers. It still has a matt look, so I didn't make it glow shiny. Any ideas?

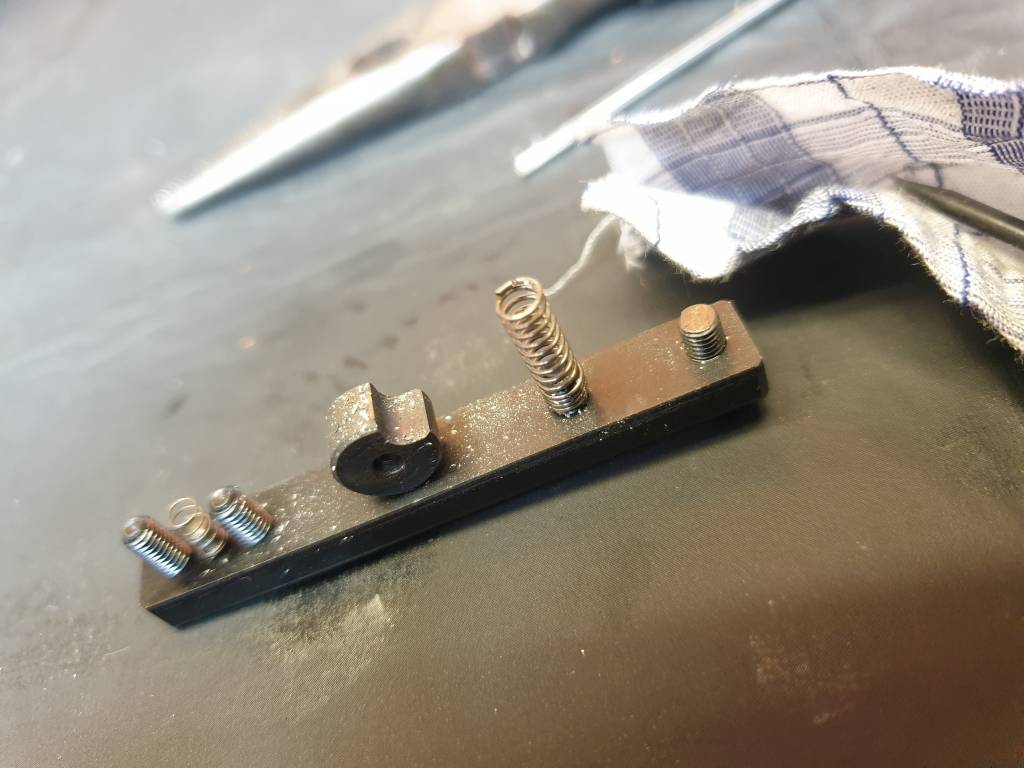

Picture shows the shiny flakes.

So I put it all back together, and the small sear that latches onto the ridge around the hammer just won't engage. It slides past, but won't "hook up", and so the gun won't cock. It is the right way around too.

So in polishing the hammer, have I taken a micro edge off the hammer engagement ridge part? I didn't do anything more than hold 600 grit wet and dry onto this ridge and twirl with my fingers. It still has a matt look, so I didn't make it glow shiny. Any ideas?

Picture shows the shiny flakes.