So I purchased my Daystate Huntsman Regal XL .22cal back in January 2017 from AoA. I've been filling it with my Hill MKIV Hand Pump but I later purchased a 97cu.ft. Great White CF Tank from Joe Brancato (airtanksforsale.com) back in September 2017 and I've been happy ever since. I noticed it developed a slow leak sometime back in July or August 2017. I monitored it and noticed it would leak about 60 to 70 BAR a week after filling it from 150 BAR to 210 BAR. I always made sure to top it off before pest hunting or any shooting sessions. I'm not sure what happened as far as it developing the leak. Maybe it was that one time after a shooting session when I left it inside my truck for over a week in the hot sun.

The highest I filled it to was 230 BAR when I was testing different pellets and running it through the chrony. Other than that, I've been filling it to 210 BAR which is the sweet spot that gives me the lowest extreme spread and best accuracy. I knew that I would eventually have to fix it because I was wasting air and having to fill it from 130/150 BAR to 210 BAR when the weekend came around which started to annoy me. The farthest I've taken it apart was just removing the stock to install some sling studs. Other than that, I was too afraid to take apart the whole rifle to try and fix the leak. Maybe it was that thread I came across when that dude's PCP rifle exploded on him after he was modifying it and the air cylinder stuck into the ceiling and part of the valve went through his thigh. Yikes!!!

I started to do some research on the airgun forums and tried to find a decent YouTube video that showed the whole process of disassembling the rifle but could never find one that was complete. It was just enough to get me by. I later recalled that JKing (Jimmy) here on AGN had posted a thread about fixing the leak in his Huntsman with some detailed pics and instructions. I reached out to him via the messaging system here on AGN and responded shortly thereafter. He re-posted his old thread via email and answered any questions that I had regarding the process of detail stripping the rifle. We have some great forum members here on AGN. Thanks again Jimmy.

Now I could have easily packed up my rifle and sent it to AoA to have them fix the leak but I didn't want to worry about all the shipping drama. Also, I wanted to learn how to fix it myself and learn how the rifle worked. So I called AoA to ask them if they had a re-seal kit for the Huntsman because I couldn't find it on their website. The sales rep informed me that they did have the kit which cost $50.00 and that the kit included all the necessary o-rings and dowty seal washers for the Huntsman Regal in .22cal. I bit the bullet and placed the order to get me on my way. When I received the Daystate Huntsman Regal .22 Complete Re-Seal Kit (Listed on invoice), it did not come with any parts list with the size of the o-rings and dowty seal washers. I don't know if Daystate or AoA is the one packaging these for sale but for $50.00, it should at least come with a parts list and maybe even an instruction sheet. Here's a couple pics of the Re-Seal Kit...

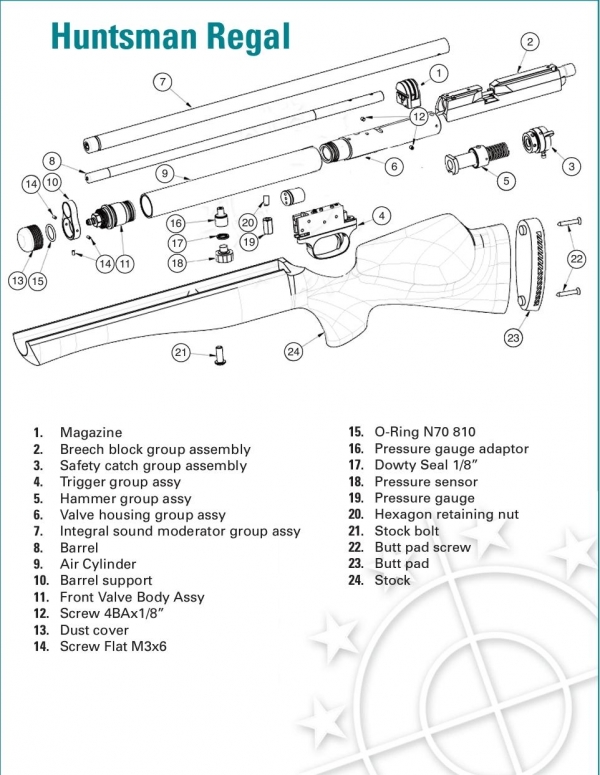

Before any disassembly is done, I do recommend that you have, purchase or borrow the proper tools for the job. Trust me. This advice is coming from a Garage Gunsmith who's boogered up a few projects in the past and continues to do so lol. Hey, I never said I was perfect and that you should take my advice seriously because after all, I'm still a newb. But on a serious note and back on topic, the tools you're going to need are some Allen Wrench Hex Key Sets in both SAE and Metric sizes. You're also going to need an Adjustable/Crescent Wrench or Open End/Box End Wrenches and some standard fixed flat head screw drivers and various dental picks to remove or install the o-rings. Here's a pic of the Huntsman Regal Exploded Parts Diagram that's in the Daystate Official Handbook on page 7 that should come with your rifle for reference.

First thing on my list was to check where the air leak was coming from so I removed the magazine and made sure it was unloaded and then removed the stock from the action.

I then placed a piece of painter's tape closest to the rear scope mount before I removed the scope as a reference point so when I re-install the scope, I wouldn't really mess up my zero.

I then lightly poured some soapy water between the three main components, the rear of the Air Cylinder (#9), Valve Housing Group Assembly (#6) and beneath the Breech Block Group Assembly/Action (#2) and I immediately noticed tiny bubbles forming from that area. Just to make sure, I also poured some soapy water on the Pressure Gauge (#18) to include the weep hole and the Pressure Gauge Adapter (#16), the breech face, the muzzle/end of the barrel, and the Front Valve Body Assembly/Male Foster Quick Fill (#11). No other bubbles formed on those areas listed except for the rear of the Air Cylinder.

Before I disassembled any other part of the rifle, I decided to let the air out first. I have seen other people start with other parts of the rifle first but I figured it would be safer to release the air in the tube while I removed the scope and the Barrel Support/Barrel Band (#10). I used an adjustable wrench and slowly turned it counter clock-wise. You could also use open box wrenches for the Pressure Gauge although I'm not sure what size would be used for it and I already had the adjustable wrench on hand. I noticed that I made several turns before the air started to release making a loud hissing sound.

I just let it sit while it slowly exhausted all the air and I noticed it took a while. I did some other stuff around the house and went back to check on it. I put my ear close to the Pressure Gauge and I could barely hear the air coming out so I slowly loosened the Pressure Gauge and more air escaped at a faster pace with a loud hiss which kind of scared me lol. One thing I didn't expect was the cold condensation on the Air Cylinder after a majority of the air was released.

After placing my ear close to the Pressure Gauge and I did not hear any air escaping, I slowly removed it from the Valve Housing Group Assembly.

Next step was to remove the Barrel Support/Barrel Band (#10). I also hear this referred to as the Figure of Eight on some videos. There are three (3 each) grub/set screws or referred to in the diagram as Screw Flat M3x6 (#14) that need to be loosened or removed before you unscrew the Air Cylinder from the Valve Housing Group Assembly. Once the screws are loosened or removed, you could slide the Barrel Support forward and off the Barrel Shroud. Keep in mind that prior to all this, I removed the factory Daystate Airstream Reflex Moderator that came attached to the Barrel Shroud because it wasn't that great.

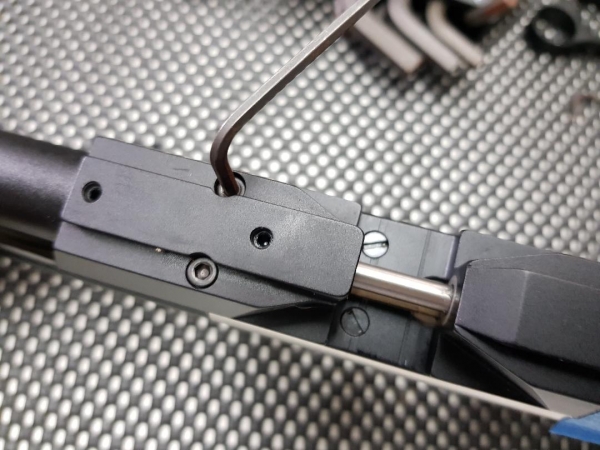

Next step is to either loosen or unscrew the six (6) bolts located on top of the Breech Block Group Assembly/Action (#2) so you will be able to unscrew the Air Cylinder. I decided that I would completely unscrew all 6 bolts from the action. There are 4 hex bolts (2 located at the front and 2 located at the rear and they are different sizes so be aware and use the correct hex keys in either metric or SAE). There are also 2 slotted screws at the breech area where the bolt probe is located.

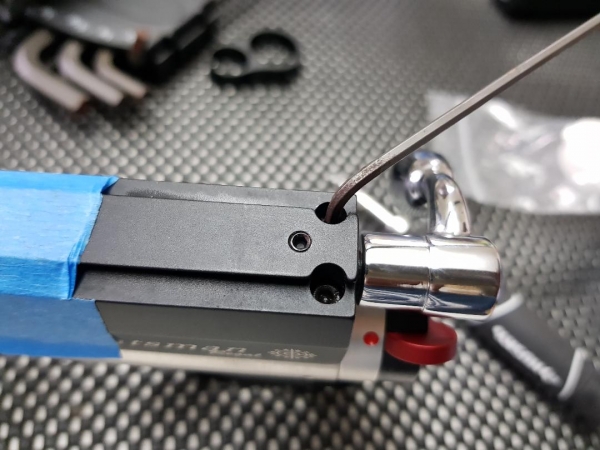

This is why I suggest that you use the proper tools for the job. In this pic, you could see that I was using a bit driver to loosen these 2 screws. The problem is that the shoulder of the bit driver gets in the way of the shoulder on the breech face so I was not able to keep it flat and I ended up stripping the head of the screw.

Once you got all 6 screws loosened, you could just lift the Breech Block Group Assembly (#2) straight up off the Valve Housing Group Assembly (#6). Be aware that there is an o-ring for the Transfer Port towards the front of the Valve Housing Group Assembly in case it falls out.

I cleaned off all the old grease and reapplied some silicone grease prior to reassembly.

Here's the Transfer Port o-ring I was talking about. You could put it to the side in case it gets lost while you're working on the Valve Housing Group Assembly.

Here's a pic of the underside of the Breech Block Group Assembly/Action (#2). You could see the brass Transfer Port located on the left by the four screw openings. That o-ring I mentioned earlier sits on the recess of the Transfer Port. You could also work the bolt and see how it functions. I did not go as far as taking the bolt apart due to time constraints. I started this project late in the day and we had a pending Tropical Storm that evening on July 4th lol. If I need to polish some areas on the bolt, I could save it for another rainy day.

The next thing I did was remove the Barrel Shroud or the proper term, Integral Sound Moderator Group Assembly (#7) but that's a mouth full and Barrel Shroud sounds better. Now you don't need to do this but for some reason, I wanted to check if it had a stainless barrel underneath the shroud and inspect it for rust. I removed the two grub/set screws at the rear of the Barrel Shroud and pulled the shroud forward. It was a little tight but I was able to wiggle it off.

Yep, it's a stainless barrel for sure.

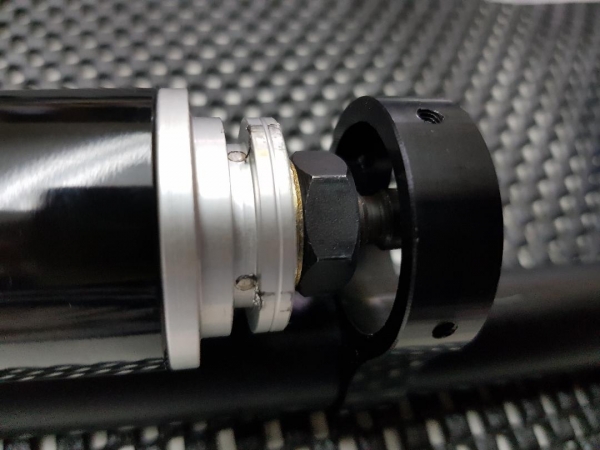

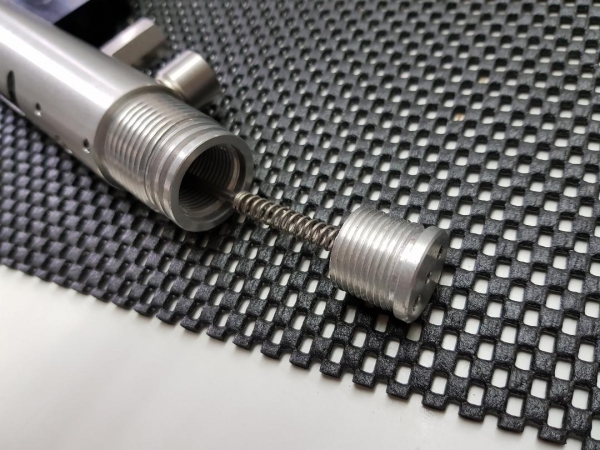

I unscrewed the Air Cylinder from the Valve Housing Group Assembly by hand. I've heard some people on the forums say that they couldn't unscrew the Air Cylinder by hand and later had to place it in a vice or use a strap wrench or a piece of leather and use channel locks or vice grips to unscrew it but mine was actually pretty easy to unscrew by hand.

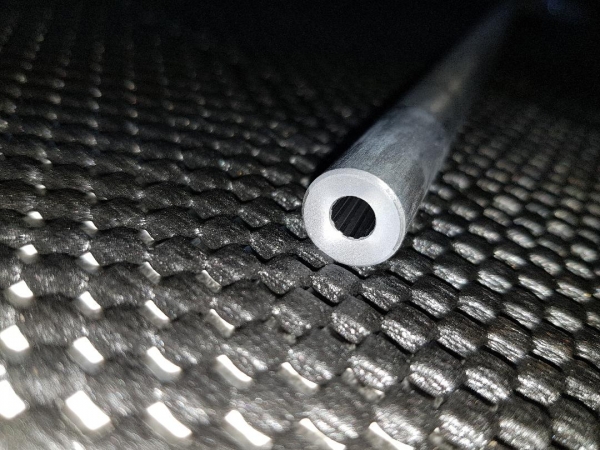

And here is the culprit, the source of my leak and problems. A busted o-ring towards the rear.

I removed both o-rings and inspected the one that looked good towards the front. I later cleaned the threads with a soft brush and canned air. This is the diver's silicone that I bought from Craig at Straight Shooters (Great guys over there). I later re-lubed the new o-ring from the kit and re-lubed the old one and placed them back on. Now I should've probably replaced the second o-ring but the kit only came with three. If it fails, at least I know how to fix it now. Here's a pic of the silicone diver's grease I purchased a while back from Straight Shooters.

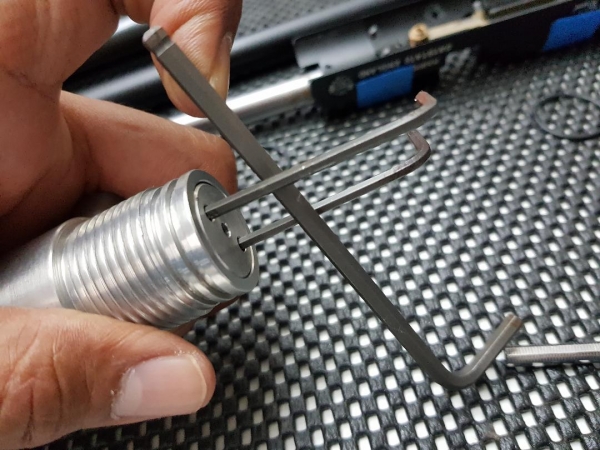

I removed the Valve Housing Group Assembly Face (Not sure what this part is exactly called if anyone wants to help me identify it). It's shown in the diagram but it's not numbered or named. I used three hex keys to unscrew it.

I also don't know what these parts are officially called if someone wants to help this newb lol.

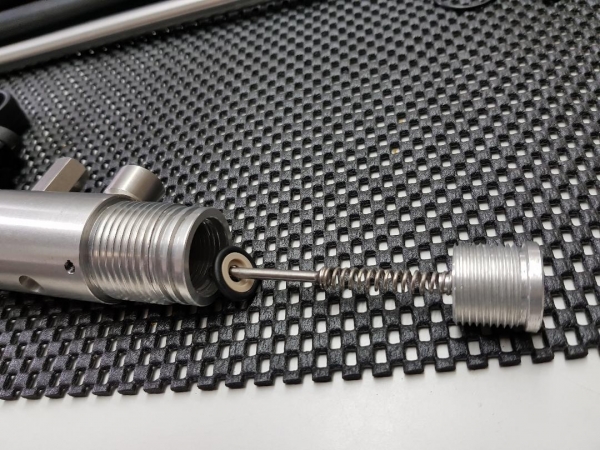

I do know that the seal sits at the bottom of the Valve Housing Group Assembly (#6). I cleaned it with a q-tip and canned air and re-lubed with silicone grease.

Front facing forward

Backside that sits flush on the Valve Housing Group Assembly (#6).

I cleaned them up, re-lubed the seal, and then placed them back inside the housing.

After making sure I cleaned and re-lubed all the seals, I re-assembled everything in reverse. I cocked the bolt and filled it with air from my Great White CF tank back up to 210 BAR and let it sit for 3 days and it finally held air.

I want to say thank you to Jking (Jimmy) and everyone who has contributed and continues to contribute to this great forum. You guys are all right in my book.

The highest I filled it to was 230 BAR when I was testing different pellets and running it through the chrony. Other than that, I've been filling it to 210 BAR which is the sweet spot that gives me the lowest extreme spread and best accuracy. I knew that I would eventually have to fix it because I was wasting air and having to fill it from 130/150 BAR to 210 BAR when the weekend came around which started to annoy me. The farthest I've taken it apart was just removing the stock to install some sling studs. Other than that, I was too afraid to take apart the whole rifle to try and fix the leak. Maybe it was that thread I came across when that dude's PCP rifle exploded on him after he was modifying it and the air cylinder stuck into the ceiling and part of the valve went through his thigh. Yikes!!!

I started to do some research on the airgun forums and tried to find a decent YouTube video that showed the whole process of disassembling the rifle but could never find one that was complete. It was just enough to get me by. I later recalled that JKing (Jimmy) here on AGN had posted a thread about fixing the leak in his Huntsman with some detailed pics and instructions. I reached out to him via the messaging system here on AGN and responded shortly thereafter. He re-posted his old thread via email and answered any questions that I had regarding the process of detail stripping the rifle. We have some great forum members here on AGN. Thanks again Jimmy.

Now I could have easily packed up my rifle and sent it to AoA to have them fix the leak but I didn't want to worry about all the shipping drama. Also, I wanted to learn how to fix it myself and learn how the rifle worked. So I called AoA to ask them if they had a re-seal kit for the Huntsman because I couldn't find it on their website. The sales rep informed me that they did have the kit which cost $50.00 and that the kit included all the necessary o-rings and dowty seal washers for the Huntsman Regal in .22cal. I bit the bullet and placed the order to get me on my way. When I received the Daystate Huntsman Regal .22 Complete Re-Seal Kit (Listed on invoice), it did not come with any parts list with the size of the o-rings and dowty seal washers. I don't know if Daystate or AoA is the one packaging these for sale but for $50.00, it should at least come with a parts list and maybe even an instruction sheet. Here's a couple pics of the Re-Seal Kit...

Before any disassembly is done, I do recommend that you have, purchase or borrow the proper tools for the job. Trust me. This advice is coming from a Garage Gunsmith who's boogered up a few projects in the past and continues to do so lol. Hey, I never said I was perfect and that you should take my advice seriously because after all, I'm still a newb. But on a serious note and back on topic, the tools you're going to need are some Allen Wrench Hex Key Sets in both SAE and Metric sizes. You're also going to need an Adjustable/Crescent Wrench or Open End/Box End Wrenches and some standard fixed flat head screw drivers and various dental picks to remove or install the o-rings. Here's a pic of the Huntsman Regal Exploded Parts Diagram that's in the Daystate Official Handbook on page 7 that should come with your rifle for reference.

First thing on my list was to check where the air leak was coming from so I removed the magazine and made sure it was unloaded and then removed the stock from the action.

I then placed a piece of painter's tape closest to the rear scope mount before I removed the scope as a reference point so when I re-install the scope, I wouldn't really mess up my zero.

I then lightly poured some soapy water between the three main components, the rear of the Air Cylinder (#9), Valve Housing Group Assembly (#6) and beneath the Breech Block Group Assembly/Action (#2) and I immediately noticed tiny bubbles forming from that area. Just to make sure, I also poured some soapy water on the Pressure Gauge (#18) to include the weep hole and the Pressure Gauge Adapter (#16), the breech face, the muzzle/end of the barrel, and the Front Valve Body Assembly/Male Foster Quick Fill (#11). No other bubbles formed on those areas listed except for the rear of the Air Cylinder.

Before I disassembled any other part of the rifle, I decided to let the air out first. I have seen other people start with other parts of the rifle first but I figured it would be safer to release the air in the tube while I removed the scope and the Barrel Support/Barrel Band (#10). I used an adjustable wrench and slowly turned it counter clock-wise. You could also use open box wrenches for the Pressure Gauge although I'm not sure what size would be used for it and I already had the adjustable wrench on hand. I noticed that I made several turns before the air started to release making a loud hissing sound.

I just let it sit while it slowly exhausted all the air and I noticed it took a while. I did some other stuff around the house and went back to check on it. I put my ear close to the Pressure Gauge and I could barely hear the air coming out so I slowly loosened the Pressure Gauge and more air escaped at a faster pace with a loud hiss which kind of scared me lol. One thing I didn't expect was the cold condensation on the Air Cylinder after a majority of the air was released.

After placing my ear close to the Pressure Gauge and I did not hear any air escaping, I slowly removed it from the Valve Housing Group Assembly.

Next step was to remove the Barrel Support/Barrel Band (#10). I also hear this referred to as the Figure of Eight on some videos. There are three (3 each) grub/set screws or referred to in the diagram as Screw Flat M3x6 (#14) that need to be loosened or removed before you unscrew the Air Cylinder from the Valve Housing Group Assembly. Once the screws are loosened or removed, you could slide the Barrel Support forward and off the Barrel Shroud. Keep in mind that prior to all this, I removed the factory Daystate Airstream Reflex Moderator that came attached to the Barrel Shroud because it wasn't that great.

Next step is to either loosen or unscrew the six (6) bolts located on top of the Breech Block Group Assembly/Action (#2) so you will be able to unscrew the Air Cylinder. I decided that I would completely unscrew all 6 bolts from the action. There are 4 hex bolts (2 located at the front and 2 located at the rear and they are different sizes so be aware and use the correct hex keys in either metric or SAE). There are also 2 slotted screws at the breech area where the bolt probe is located.

This is why I suggest that you use the proper tools for the job. In this pic, you could see that I was using a bit driver to loosen these 2 screws. The problem is that the shoulder of the bit driver gets in the way of the shoulder on the breech face so I was not able to keep it flat and I ended up stripping the head of the screw.

Once you got all 6 screws loosened, you could just lift the Breech Block Group Assembly (#2) straight up off the Valve Housing Group Assembly (#6). Be aware that there is an o-ring for the Transfer Port towards the front of the Valve Housing Group Assembly in case it falls out.

I cleaned off all the old grease and reapplied some silicone grease prior to reassembly.

Here's the Transfer Port o-ring I was talking about. You could put it to the side in case it gets lost while you're working on the Valve Housing Group Assembly.

Here's a pic of the underside of the Breech Block Group Assembly/Action (#2). You could see the brass Transfer Port located on the left by the four screw openings. That o-ring I mentioned earlier sits on the recess of the Transfer Port. You could also work the bolt and see how it functions. I did not go as far as taking the bolt apart due to time constraints. I started this project late in the day and we had a pending Tropical Storm that evening on July 4th lol. If I need to polish some areas on the bolt, I could save it for another rainy day.

The next thing I did was remove the Barrel Shroud or the proper term, Integral Sound Moderator Group Assembly (#7) but that's a mouth full and Barrel Shroud sounds better. Now you don't need to do this but for some reason, I wanted to check if it had a stainless barrel underneath the shroud and inspect it for rust. I removed the two grub/set screws at the rear of the Barrel Shroud and pulled the shroud forward. It was a little tight but I was able to wiggle it off.

Yep, it's a stainless barrel for sure.

I unscrewed the Air Cylinder from the Valve Housing Group Assembly by hand. I've heard some people on the forums say that they couldn't unscrew the Air Cylinder by hand and later had to place it in a vice or use a strap wrench or a piece of leather and use channel locks or vice grips to unscrew it but mine was actually pretty easy to unscrew by hand.

And here is the culprit, the source of my leak and problems. A busted o-ring towards the rear.

I removed both o-rings and inspected the one that looked good towards the front. I later cleaned the threads with a soft brush and canned air. This is the diver's silicone that I bought from Craig at Straight Shooters (Great guys over there). I later re-lubed the new o-ring from the kit and re-lubed the old one and placed them back on. Now I should've probably replaced the second o-ring but the kit only came with three. If it fails, at least I know how to fix it now. Here's a pic of the silicone diver's grease I purchased a while back from Straight Shooters.

I removed the Valve Housing Group Assembly Face (Not sure what this part is exactly called if anyone wants to help me identify it). It's shown in the diagram but it's not numbered or named. I used three hex keys to unscrew it.

I also don't know what these parts are officially called if someone wants to help this newb lol.

I do know that the seal sits at the bottom of the Valve Housing Group Assembly (#6). I cleaned it with a q-tip and canned air and re-lubed with silicone grease.

Front facing forward

Backside that sits flush on the Valve Housing Group Assembly (#6).

I cleaned them up, re-lubed the seal, and then placed them back inside the housing.

After making sure I cleaned and re-lubed all the seals, I re-assembled everything in reverse. I cocked the bolt and filled it with air from my Great White CF tank back up to 210 BAR and let it sit for 3 days and it finally held air.

I want to say thank you to Jking (Jimmy) and everyone who has contributed and continues to contribute to this great forum. You guys are all right in my book.