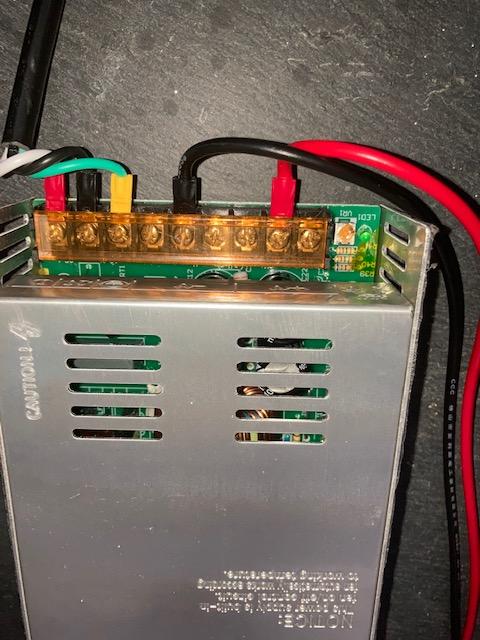

I just received my generic Chinese oil-less/waterless 12V portable air compressor that is branded under a dozen different names and versions. Some are sold by major US airgun dealers. The GROUND wire on the transformer was not properly hooked up. If there is a short and you happened to touch the transformer casing 110V electricity would travel through your body. Recommend to check your GROUND and make sure it works. I have not checked the pump yet. The pump itself is 12V only so no danger of death, but has up to 30 amps which can weld metal together if shorted (like a car battery).

How I tested for GROUND? Took a multi-meter/Ohm meter and touched one probe to unplugged center/lower pin of the 110V plug. The other probe to the case of the transformer. Note that the case is covered almost entirely with a very thin plastic sticky sheet (like the kitchen wrap) so the best is to touch the screw heads. If you do not get any readings, then the GROUND is not connected.

The easy fix:

The easiest fix is to run a ground wire directly from the green terminal of the transformer to the case of the transformer. MAKE SURE TO DISCONNECT POWER. Choose an exposed metal area that you can secure the wire with a screw or bolt. Mae sure it does not touch any components inside the case.

More involved fix:

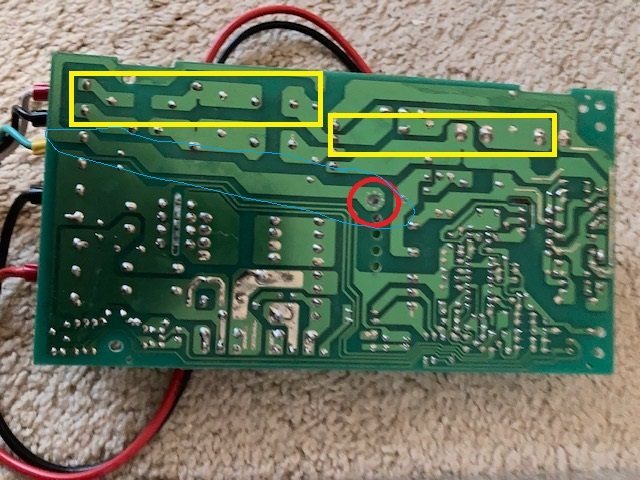

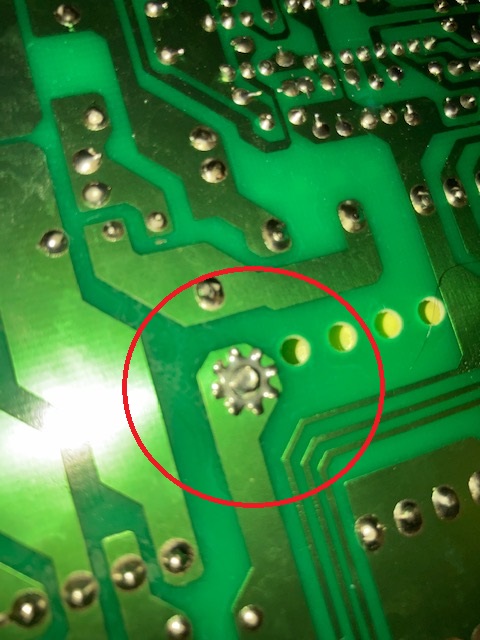

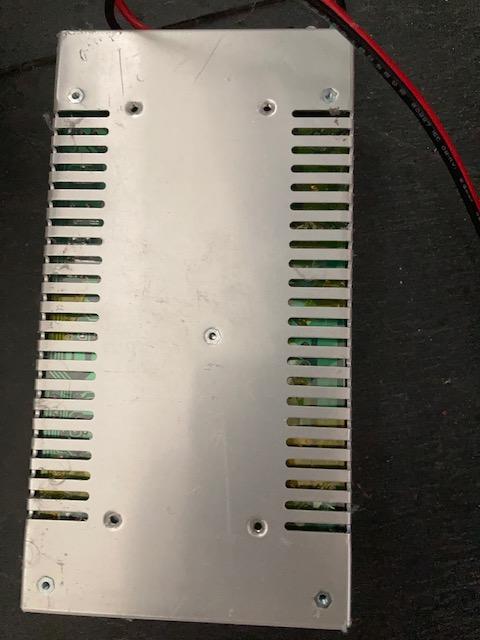

MAKE SURE TO DISCONNECT POWER. I took mine apart by taking out the 6 screws holding the top of the transformer in place. See the blue circled area as the GROUND circuit. And yellow is live 110V area.

Then I removed the two long screws that hold two brackets for two heat-sinks flush against the side of the case. Then removed the two metal brackets. When you put it back together, recommend to put a small blob of epoxy on each that prevent the brackets from turning and hitting the circuit board components. There is only 12V below them, but still could cause a 30 amps short.

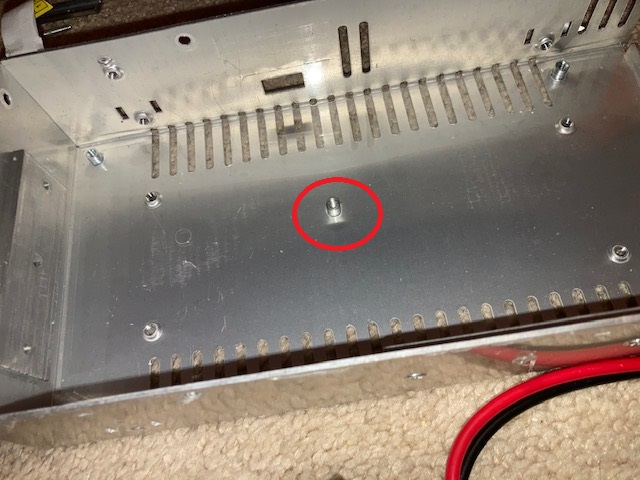

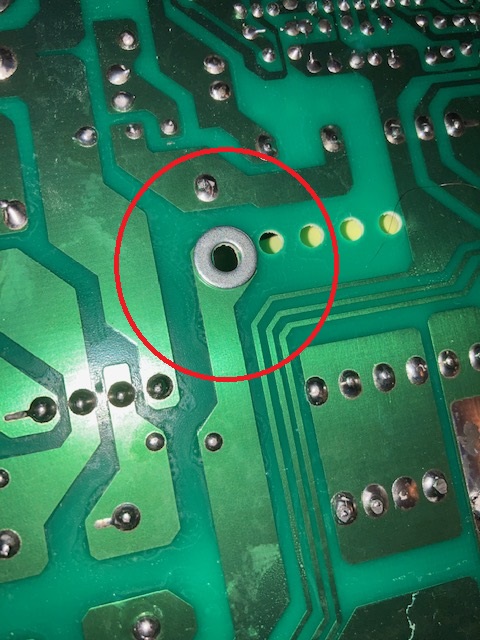

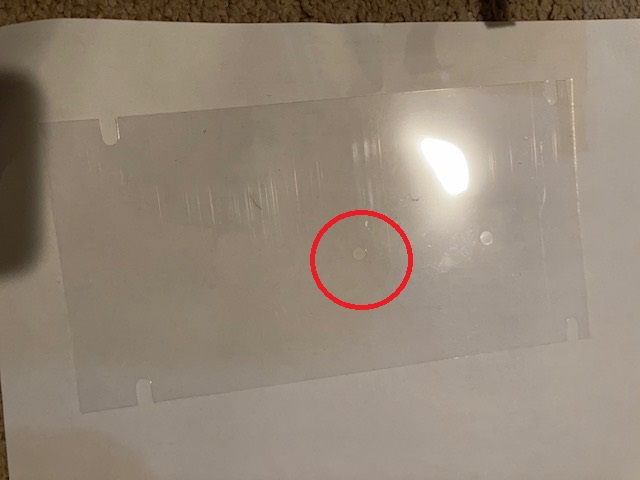

Next, remove the 3 screws holding the circuit board (maybe be more for you) including the middle one that is supposed to be the ground. Slide out the circuit board to the front. Careful with the two heat-sink assemblies. Remove the thin plastic safety-insulating sheet (barely can see it) from the bottom of the case. In the middle of the case is the ground terminal for the ground screw that you took out from the middle of the board. Only the bottom of the circuit board has any conductivity as far as the grounding point. But the barely visible plastic sheet may be blocking the path, so I made the hole in the sheet larger around it. There are some very small conductive pegs in a circle around the ground mounting location hole on the circuit board, but they must not have made a contact with the GROUND terminal below. Add a washer, etc between the bottom hole where the conductive circle pegs are and the GROUND terminal peg in the center of the case. I used a small blob of epoxy to keep the washer over the ground terminal socket on the case. Make sure you do not insulate it with the epoxy.

I also recommend that you secure the barely visible plastics sheet to the circuit board,(I used kapton tape in case it gets hot) to allow for ventilation of the case. If the thin plastic sheet is flush against the bottom it will block the two largest ventilation grills for the entire case. Please note that the only thing that is between you and 110 Volts is that think plastic sheet. So there should be no water, metal parts, etc ever entering the case on the bottom. The 110V live portion of the circuit board is only gapped less than 1/4 inch from the case ventilation grills and only the super-thin plastic sheet is over it.

Putting it back together: Slide in the circuit board (careful with the heat sinks) and secure the GROUND screw terminal first. The washer is underneath the circuit board. There is nothing conductive on the top of the board where the GROUND screw bolts on. Test for GROUND. Then put the rest of the circuit board screws back in their place. Also the two long heat-sink bolts. And then top of the case.

How I tested for GROUND? Took a multi-meter/Ohm meter and touched one probe to unplugged center/lower pin of the 110V plug. The other probe to the case of the transformer. Note that the case is covered almost entirely with a very thin plastic sticky sheet (like the kitchen wrap) so the best is to touch the screw heads. If you do not get any readings, then the GROUND is not connected.

The easy fix:

The easiest fix is to run a ground wire directly from the green terminal of the transformer to the case of the transformer. MAKE SURE TO DISCONNECT POWER. Choose an exposed metal area that you can secure the wire with a screw or bolt. Mae sure it does not touch any components inside the case.

More involved fix:

MAKE SURE TO DISCONNECT POWER. I took mine apart by taking out the 6 screws holding the top of the transformer in place. See the blue circled area as the GROUND circuit. And yellow is live 110V area.

Then I removed the two long screws that hold two brackets for two heat-sinks flush against the side of the case. Then removed the two metal brackets. When you put it back together, recommend to put a small blob of epoxy on each that prevent the brackets from turning and hitting the circuit board components. There is only 12V below them, but still could cause a 30 amps short.

Next, remove the 3 screws holding the circuit board (maybe be more for you) including the middle one that is supposed to be the ground. Slide out the circuit board to the front. Careful with the two heat-sink assemblies. Remove the thin plastic safety-insulating sheet (barely can see it) from the bottom of the case. In the middle of the case is the ground terminal for the ground screw that you took out from the middle of the board. Only the bottom of the circuit board has any conductivity as far as the grounding point. But the barely visible plastic sheet may be blocking the path, so I made the hole in the sheet larger around it. There are some very small conductive pegs in a circle around the ground mounting location hole on the circuit board, but they must not have made a contact with the GROUND terminal below. Add a washer, etc between the bottom hole where the conductive circle pegs are and the GROUND terminal peg in the center of the case. I used a small blob of epoxy to keep the washer over the ground terminal socket on the case. Make sure you do not insulate it with the epoxy.

I also recommend that you secure the barely visible plastics sheet to the circuit board,(I used kapton tape in case it gets hot) to allow for ventilation of the case. If the thin plastic sheet is flush against the bottom it will block the two largest ventilation grills for the entire case. Please note that the only thing that is between you and 110 Volts is that think plastic sheet. So there should be no water, metal parts, etc ever entering the case on the bottom. The 110V live portion of the circuit board is only gapped less than 1/4 inch from the case ventilation grills and only the super-thin plastic sheet is over it.

Putting it back together: Slide in the circuit board (careful with the heat sinks) and secure the GROUND screw terminal first. The washer is underneath the circuit board. There is nothing conductive on the top of the board where the GROUND screw bolts on. Test for GROUND. Then put the rest of the circuit board screws back in their place. Also the two long heat-sink bolts. And then top of the case.