G

Guest

Guest

This is Part Five and should be the last thread I create on the topic.

Links to other threads on this topic:

Part One

Part Two

Part Three

Part Four

Part Five

Purpose of this thread is to

I believe I have shown the method works substantially even with "good" pellets but (being an objective observer) also believe that further data needs to be available here which either supports my conclusion or refutes that opinion.

I will document the machine I built and am using to test in this spot as soon as time permits. Meanwhile entertain yourself with this experimental data or better still collect some yourself and post your results in this thread. Do remember the contents of the video linked at the top of part three.

https://www.youtube.com/watch?v=DVGoby1fggY

3d STL files for the Rolling Machine

Here is a test I ran today. I had time today and was testing the roller I am designing, checking an improvement. The wind was just right and I happened to notice. So I took the opportunity. I shot one of the tests I had prepared for tomorrow. I shot outdoors at 25 meters vice indoors at 25 yards. That test (tomorrow's test) is here but I'll used the HW-98 for that as it is already part of the study.

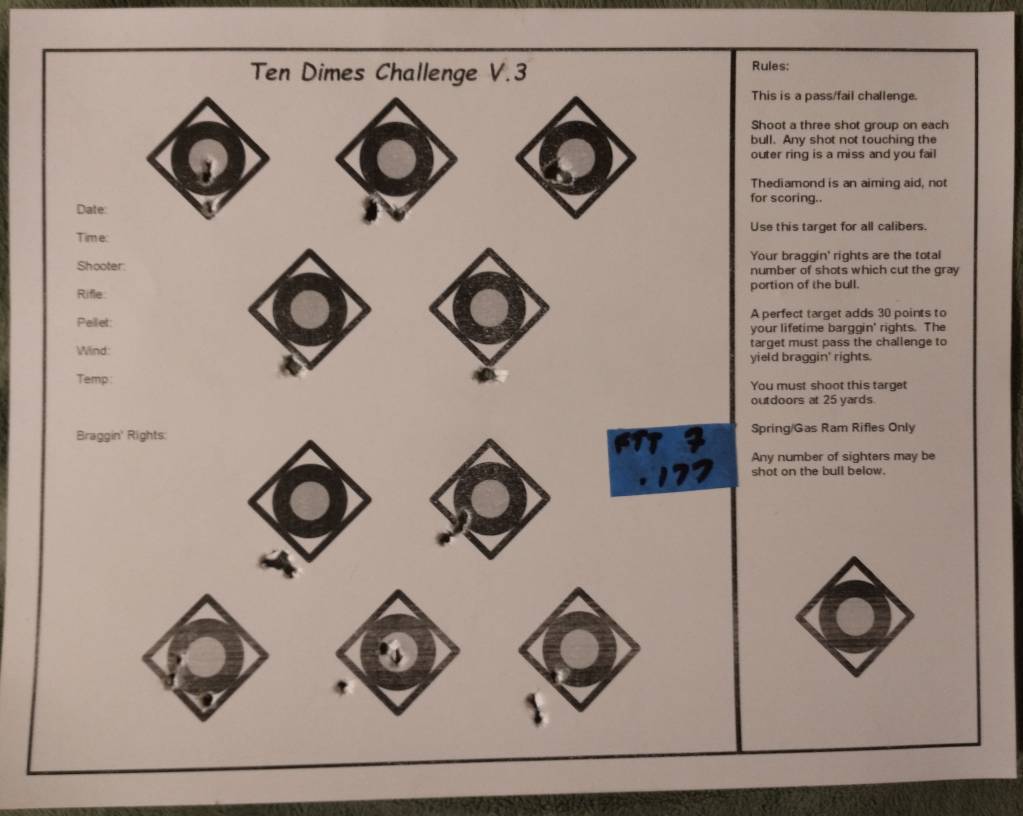

I rolled enough pellets from a fresh tin of H&N FTTs in 0.177 and shot the ten dimes challenge three times. Once with a control group from the tin and then a second and third time with test groups which had been classified on the roller. I named those groups #8 and #7 simply because of the cells they landed in during the roll test. The modified roller is now showing an error rate of about 2%.

Here are those results, the spread sheets are linked at the top.

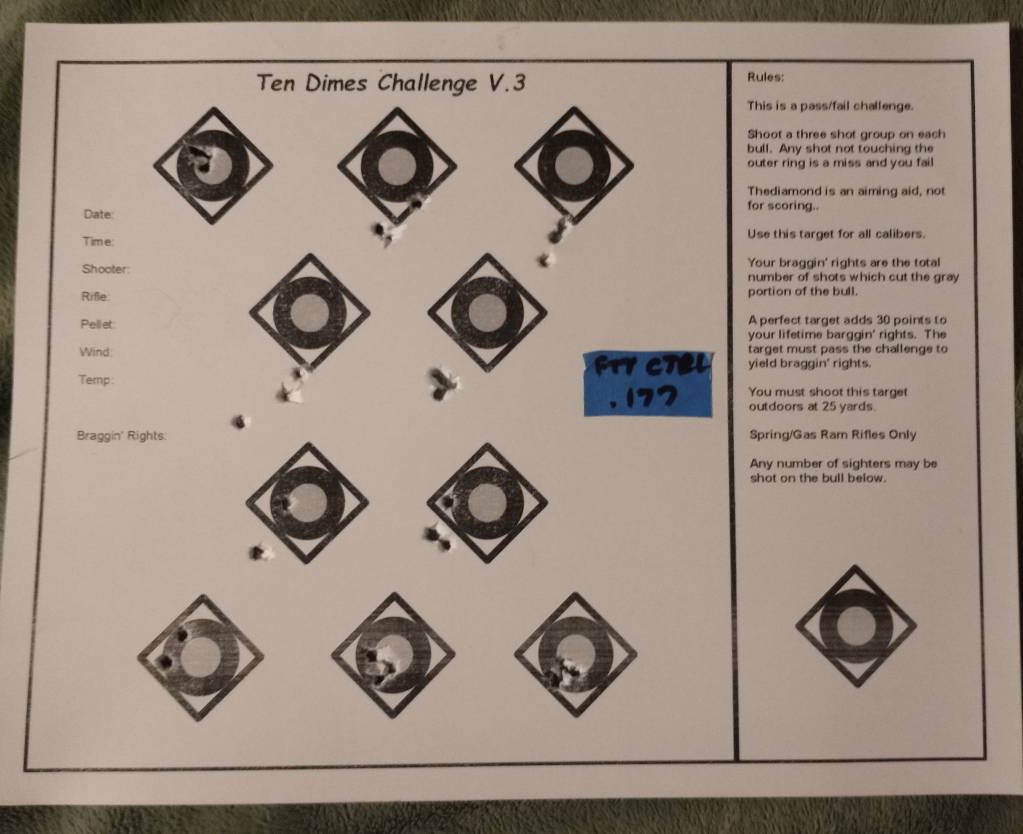

Control Group, 30 shots, 25 meters from the tin.

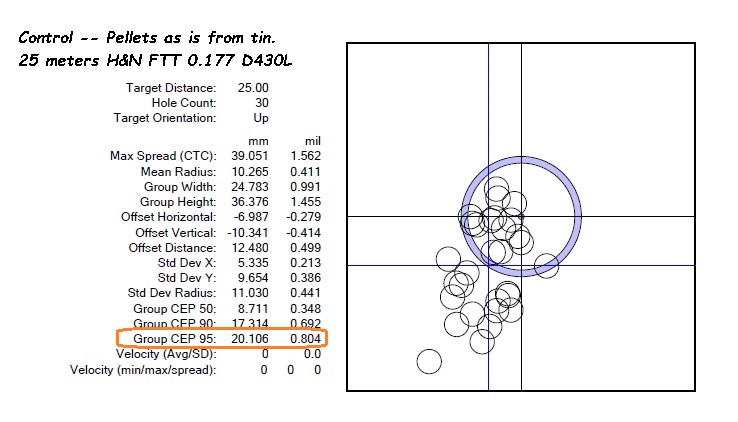

Aggregate group for the control target:

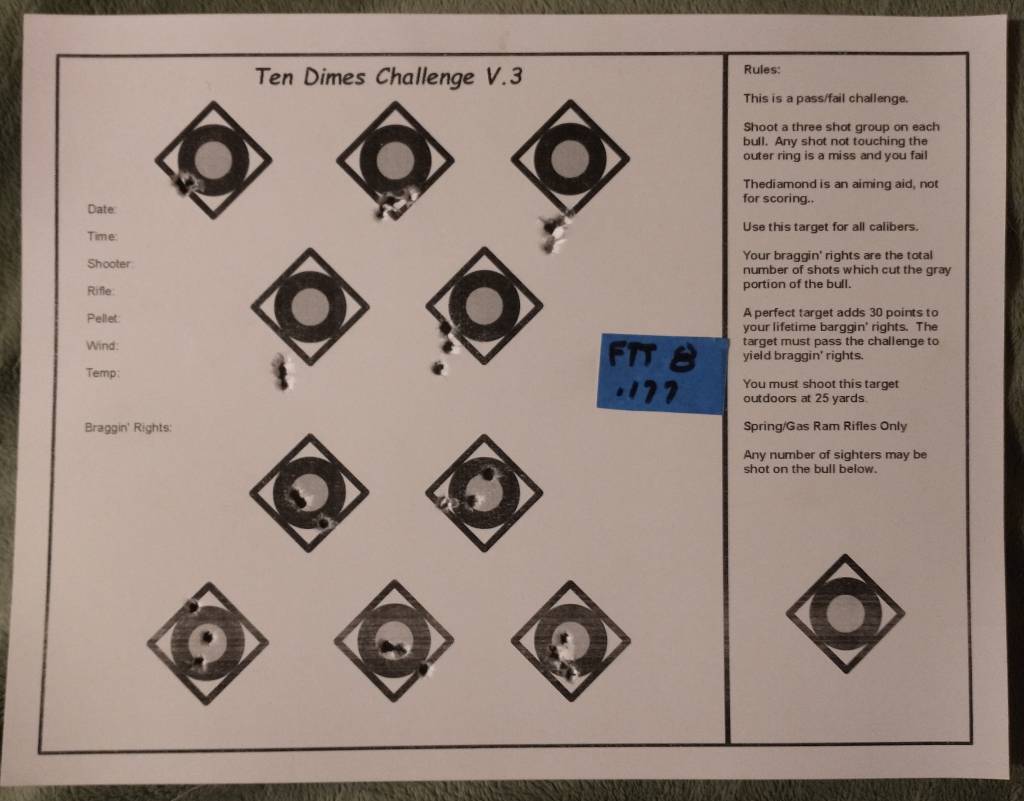

Test Group #8

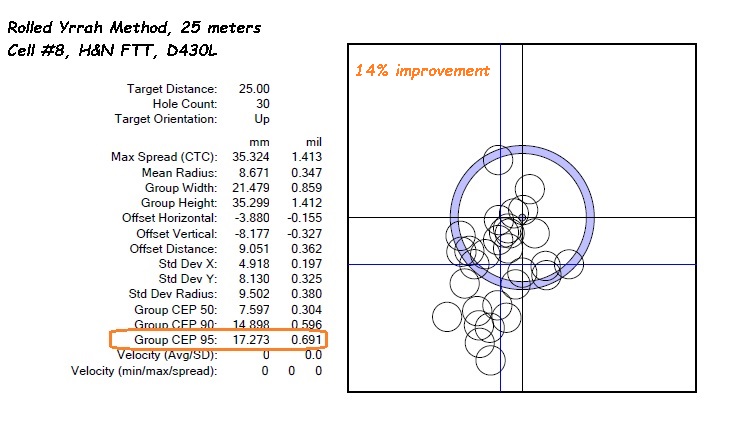

Aggregate of test groups for #8

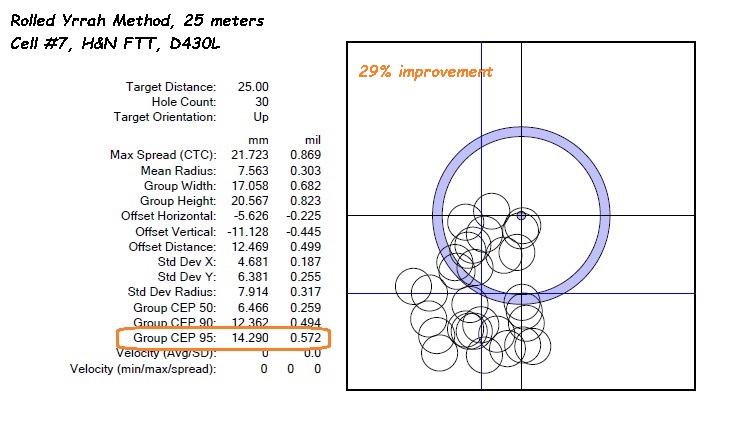

Test group #7

Aggregate for test group #7

Both test groups show an improvement in group size. This pellet is the best pellet I have found for this rifle. The weather conditions while shooting were 80f, overcast, light and variable winds 2 to 5 mph. Three range flags are on the range at 10, 20, and 30 yards. I tried to watch the flags and shoot during consistent conditions. I did not hold off for wind. I waited for wind.

Data collected for this experiment:

View attachment ftt-7.1628044374.csv

View attachment ftt-7.1628044374.csv

View attachment ftt-8.1628044374.csv

View attachment ftt-8.1628044374.csv

View attachment ftt-ctrl.1628044374.csv

View attachment ftt-ctrl.1628044374.csv

Links to other threads on this topic:

Part One

Part Two

Part Three

Part Four

Part Five

Purpose of this thread is to

- document the Yrrah Rolling Machine as I implemented it.

- provide a point of collection for peoples anecdotal (or experimental) comments with respect to the Yrrah pellet rolling method, as first documented by "Harry in Os" AKA @Yrrah on this forum and also others. By all means add your opinions and results whether anecdotal or actual experimental results to this thread.

- Provide a single thread where I can post results of my continued testing of this method.

I believe I have shown the method works substantially even with "good" pellets but (being an objective observer) also believe that further data needs to be available here which either supports my conclusion or refutes that opinion.

I will document the machine I built and am using to test in this spot as soon as time permits. Meanwhile entertain yourself with this experimental data or better still collect some yourself and post your results in this thread. Do remember the contents of the video linked at the top of part three.

https://www.youtube.com/watch?v=DVGoby1fggY

3d STL files for the Rolling Machine

Here is a test I ran today. I had time today and was testing the roller I am designing, checking an improvement. The wind was just right and I happened to notice. So I took the opportunity. I shot one of the tests I had prepared for tomorrow. I shot outdoors at 25 meters vice indoors at 25 yards. That test (tomorrow's test) is here but I'll used the HW-98 for that as it is already part of the study.

I rolled enough pellets from a fresh tin of H&N FTTs in 0.177 and shot the ten dimes challenge three times. Once with a control group from the tin and then a second and third time with test groups which had been classified on the roller. I named those groups #8 and #7 simply because of the cells they landed in during the roll test. The modified roller is now showing an error rate of about 2%.

Here are those results, the spread sheets are linked at the top.

Control Group, 30 shots, 25 meters from the tin.

Aggregate group for the control target:

Test Group #8

Aggregate of test groups for #8

Test group #7

Aggregate for test group #7

Both test groups show an improvement in group size. This pellet is the best pellet I have found for this rifle. The weather conditions while shooting were 80f, overcast, light and variable winds 2 to 5 mph. Three range flags are on the range at 10, 20, and 30 yards. I tried to watch the flags and shoot during consistent conditions. I did not hold off for wind. I waited for wind.

Data collected for this experiment: