This is a guide on how to cut and finish airgun sprIng, the same technique can be used on the main spring on a spring powered airgun or the hammer and valve return springs on a PCP. The main reasons for cutting the spring is its a cheap and effective way to help balance the tune of a pcp, or to reduce the power or harsh firing cycle of a springer.

The illustration are from a Rapid/RAW hammer spring

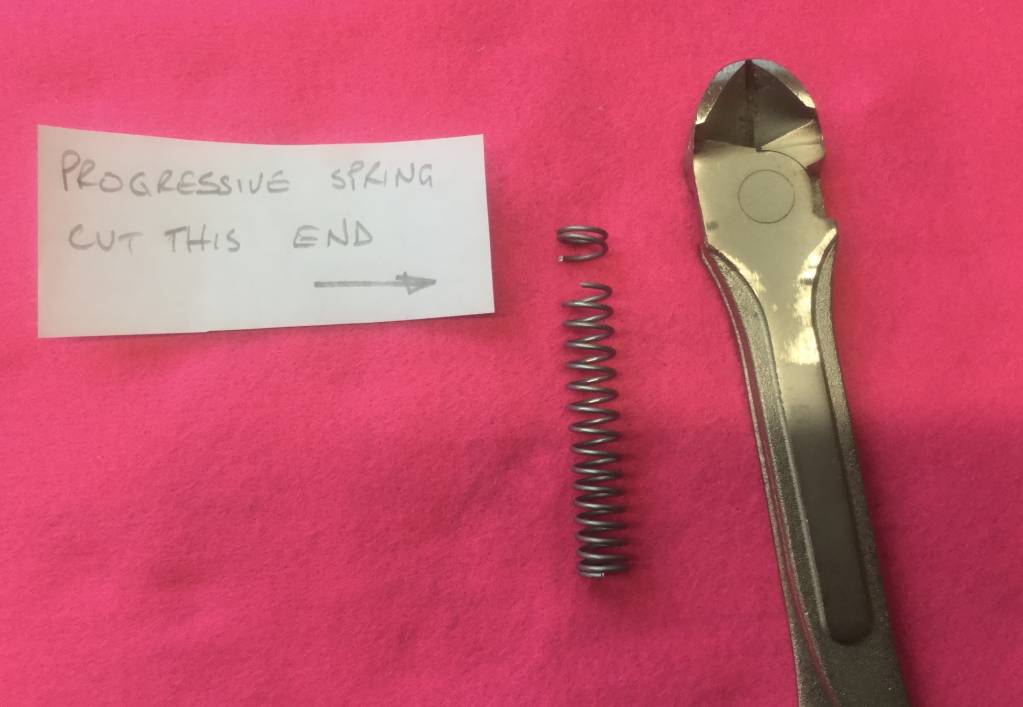

With a quality pair of snips, bolt cropper, dremel or grinder cut the coil. There are two main type of springs frequently used, fixed rate or progressive. Both can be cut from either end but progressive springs are best cut from the loose coil end.

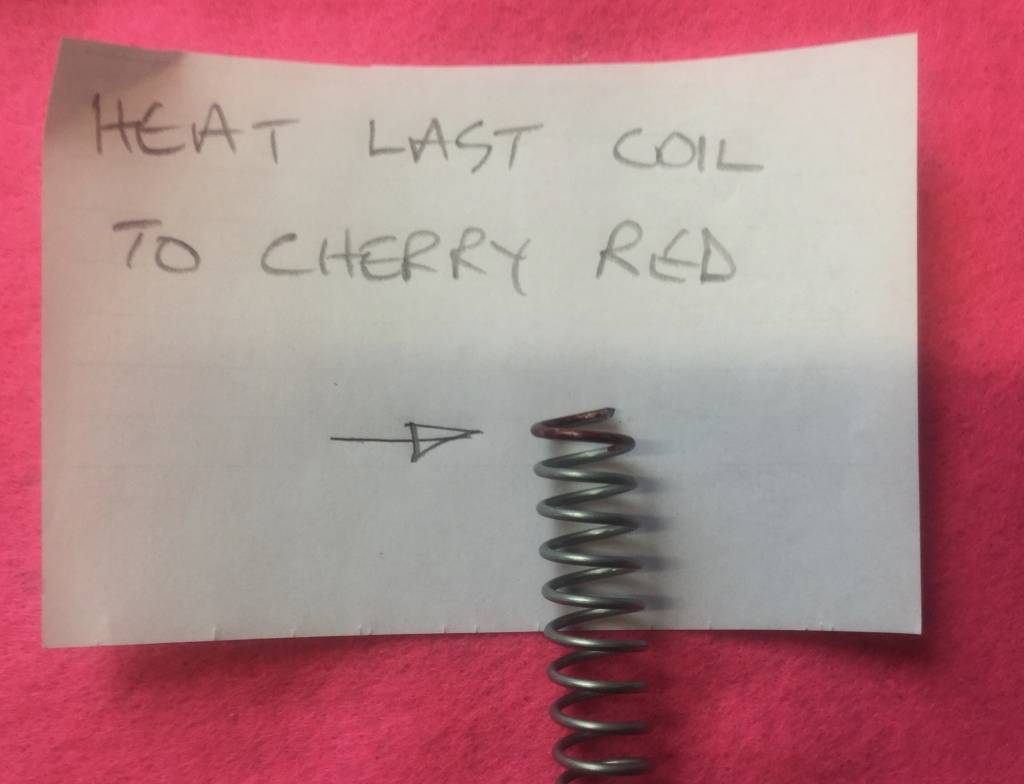

With a blow torch or gas kitchen hob heat the last coil until cherry red

Once red, immediately push down onto a flat surface.

With a grinder, sanding disc or a sheet of emery paper on a flat surface, carefully flatten the coil.

With a dowel in a drill, polish both the internal and external surface to ensure it’s as smooth as possible

When done, it should look something like this.

it only takes a few minutes to cut and finish a spring, IMO well worth effort, I believe it makes the action smoother and more consistent

Bb

The illustration are from a Rapid/RAW hammer spring

With a quality pair of snips, bolt cropper, dremel or grinder cut the coil. There are two main type of springs frequently used, fixed rate or progressive. Both can be cut from either end but progressive springs are best cut from the loose coil end.

With a blow torch or gas kitchen hob heat the last coil until cherry red

Once red, immediately push down onto a flat surface.

With a grinder, sanding disc or a sheet of emery paper on a flat surface, carefully flatten the coil.

With a dowel in a drill, polish both the internal and external surface to ensure it’s as smooth as possible

When done, it should look something like this.

it only takes a few minutes to cut and finish a spring, IMO well worth effort, I believe it makes the action smoother and more consistent

Bb