So after many unsuccessful inquiries, I decided to make my own.

and what you'll need:

Delrin rod

1/8" drill bit

Junior (6") hacksaw or similar. I used a 32 teeth blade that I bought from Lowes.

Sand paper and Flat file ( I forgot to put it in picture)

Small round file (optional) but very convenient. You can buy a whole set from Harbor Freight or Northern Tools.

Caliper

Drill

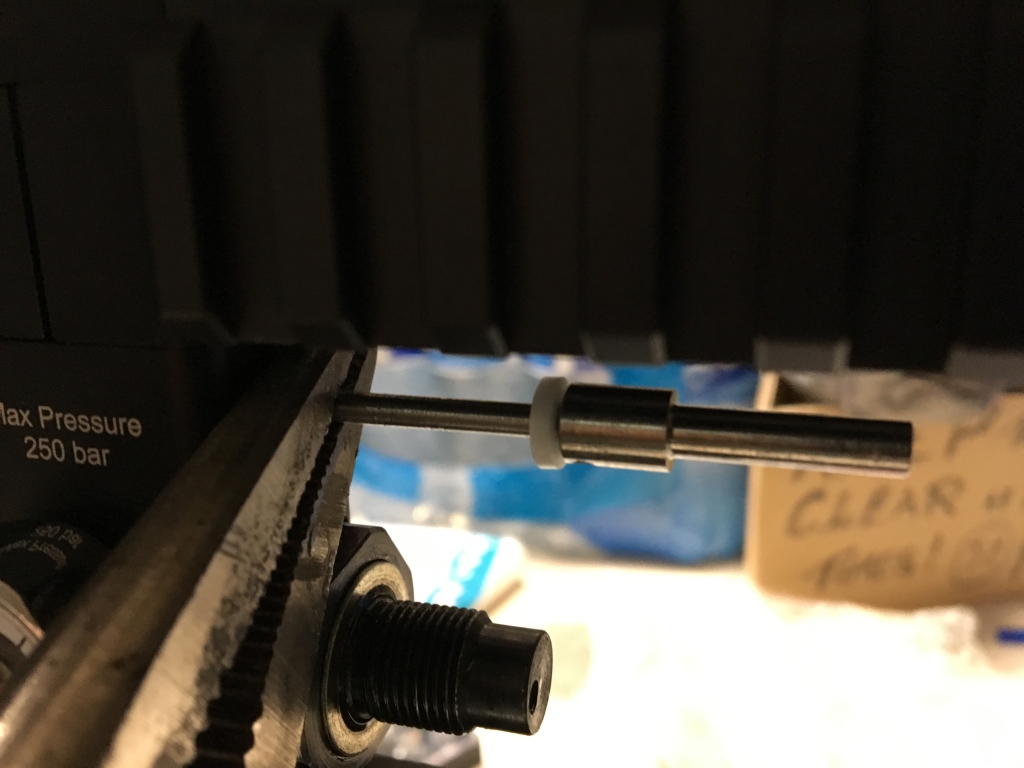

Now, Clamp the Rod in a very stable vice or something like a JawHorse ( I used this).

With steady hands drill a hole, well centered, using the 1/8" bit. Don't go larger or the hole will be too big as you will use the file to smooth it out. Drill about 1" or more into the rod.

With rod still clamped, adjust it so you can cut off some sections to make your washers (bumpers). I made a few with varying thickness of 1.4mm to 1.6mm. Make your cuts a little thicker than you need because you'll need to sand it to the correct thickness.

Use your flat file and sandpaper to get things nice and finished to your specification. Use the caliper to confirm the thickness.

Note: On my Impact X, the Rod's thickness was 3.13mm in diameter, so you do not want to use a larger drill bit than I/8".

On the photo you'll notice some of my finished bumpers along with the original greenish color stretched O-ring that came off the gun, and the 2 others from 2 different suppliers.

I do hope that this was helpful to some of you. Good luck

Funshine

and what you'll need:

Delrin rod

1/8" drill bit

Junior (6") hacksaw or similar. I used a 32 teeth blade that I bought from Lowes.

Sand paper and Flat file ( I forgot to put it in picture)

Small round file (optional) but very convenient. You can buy a whole set from Harbor Freight or Northern Tools.

Caliper

Drill

Now, Clamp the Rod in a very stable vice or something like a JawHorse ( I used this).

With steady hands drill a hole, well centered, using the 1/8" bit. Don't go larger or the hole will be too big as you will use the file to smooth it out. Drill about 1" or more into the rod.

With rod still clamped, adjust it so you can cut off some sections to make your washers (bumpers). I made a few with varying thickness of 1.4mm to 1.6mm. Make your cuts a little thicker than you need because you'll need to sand it to the correct thickness.

Use your flat file and sandpaper to get things nice and finished to your specification. Use the caliper to confirm the thickness.

Note: On my Impact X, the Rod's thickness was 3.13mm in diameter, so you do not want to use a larger drill bit than I/8".

On the photo you'll notice some of my finished bumpers along with the original greenish color stretched O-ring that came off the gun, and the 2 others from 2 different suppliers.

I do hope that this was helpful to some of you. Good luck

Funshine