Hey guys!

I got my second Crown a couple weeks ago. Why did I get a second Crown? Well, that's a whole story I'm not going to get into right now. But I sure do miss Crown #1!

It's nice to se that they're coming with hard cases now. And, it's a nice case too. Granted, it's egg shell inside, but it's still a nice hard case.

Finally got the Blue Lam I've wanted since the first time I saw it. ?

I think it's cool how the blue hit "FX" just right.

Ah, Finally! A Crown specific instruction manual!

After a quick look over, it was time to get started with cleaning the barrel and taking "factory settings" pictures. I was surprised to see the reg set at 120b. I thought it would have been closer to 150b. No big deal to me, factory usually knows best.

After that, I got to work on seasoning the barrel and working towards getting the reg broken in. It doesn't take me long at all to be reminded of how much I dislike shooting off a dual sandbag setup. So... time to get to work installing a rail since these don't come with anything. I try to always have at least one spare picatinny rail in supply. I've been sitting on a rare "right hand" specific Royale stock that needs a rail on it as well. I figured, If I'm doing one, I might as well do both!

I tape up the area I'll be drilling and drawing on, to protect the finish of the stock and help prevent tearout.

Center and locate my rails where I want them. I like my rails to be as far forward as possible but still aesthetically pleasing. this is where I started to notice an issue.

I wanted to use T-nuts since the Crowns tongue is sooo thin. FX - Don't you think it's time to start adding some type of rail system to your stocks? Come on.

It looked fine on the bottom but, if I were to put it there, the T-nut would protrude past the edge on the top side. No good! This is why I measure twice and cut once. In "one-shot-only" cases like this, it's measure much more than twice before cautiously cutting.

Just move it back a little, right?

Nope. I'd be intruding on the gauge.

This is still a feasible option, though. I'd just customize the T-nut by cutting and edge. But, I still don't like it.

Back to the original location. If I move the screw back a little inside the oval shaped hole, I could secure the rail and have the T-nuts clear everything. Yahtzee?

2 Issues with this... A) If I locate the screw at the high point between two slots I lose BOTH slots because the screw is wider than the picatinny slot. If I locate it within the low area of the picatinny, I lose only that slot.

This might be personal preference....

B) If I put the screw within the first slot, It pushes my bipod back so far that there has to be a better option available. If I put it in the second slot it not only looks odd but, in reality, it pushes my bipod back to the third slot due to the tapered sides.

Spinning the rail around won't solve any of these issues either. So, I said "Screw it!" and decided to sleep on it and see if I could come up with another solution.

I still managed to get the Royale stock done though. I decided to tap the holes for this one since the stock tongue is a little thicker.

On to the next difficulty... Tuning.

One of the benefits of the Crown is its ability to be tuned by the shooter. Thank goodness! In this case, it needs it straight out of the box!

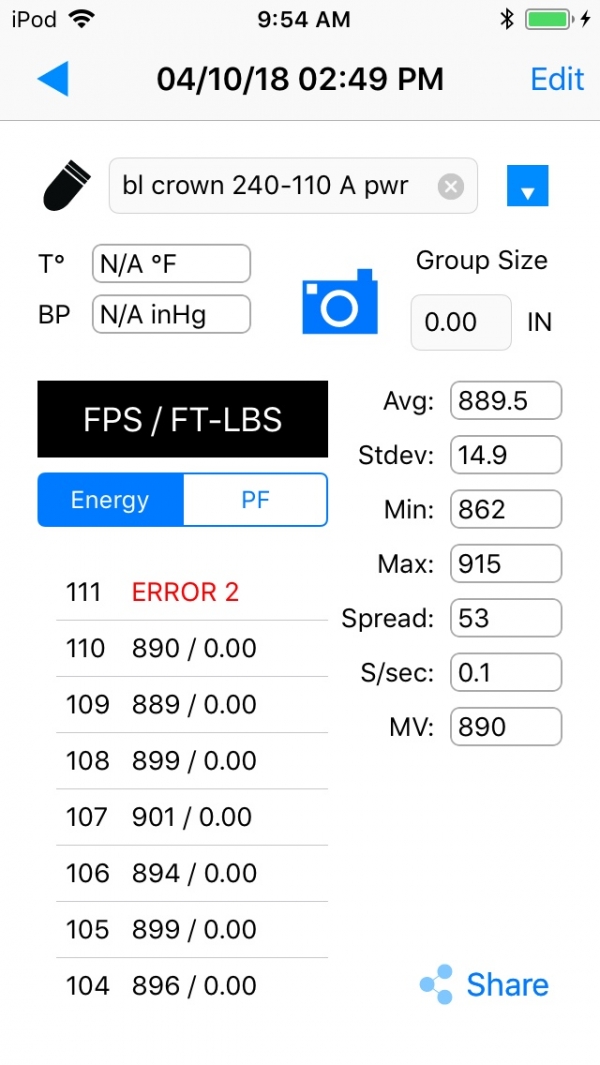

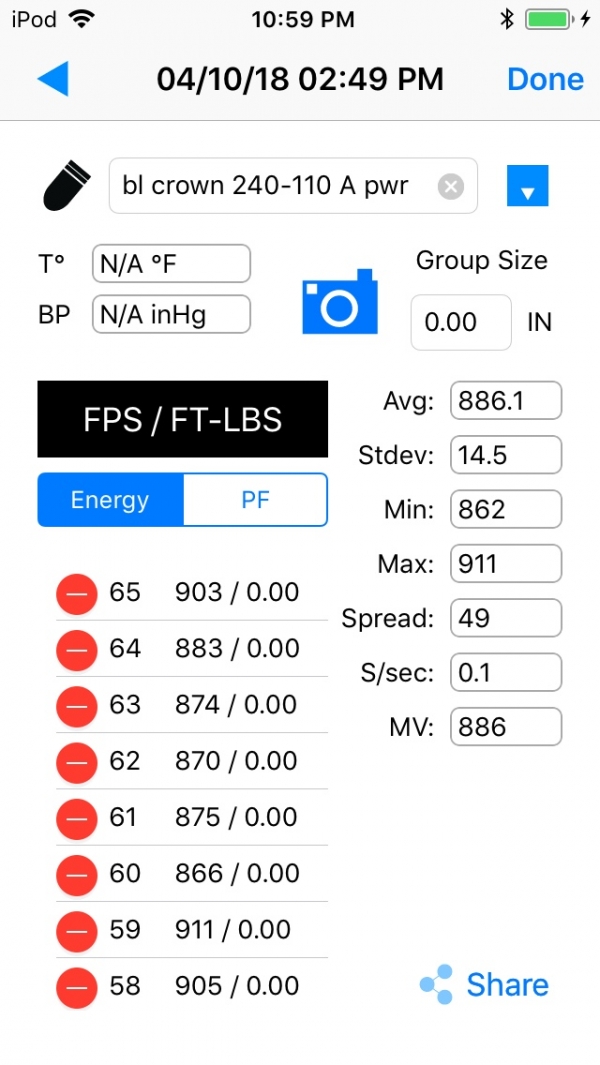

ES of 53? FX... I expected better than this.

Ok, Ok... Before you get into the "well, this" and "well that..."

Reg reading 120b, "A" power level, and I shot 110 shots from 240-110. So, it bumped up when it fell off the reg, right? I can accept that. It hit 915fps at shot #87 so, it's totally plausible.

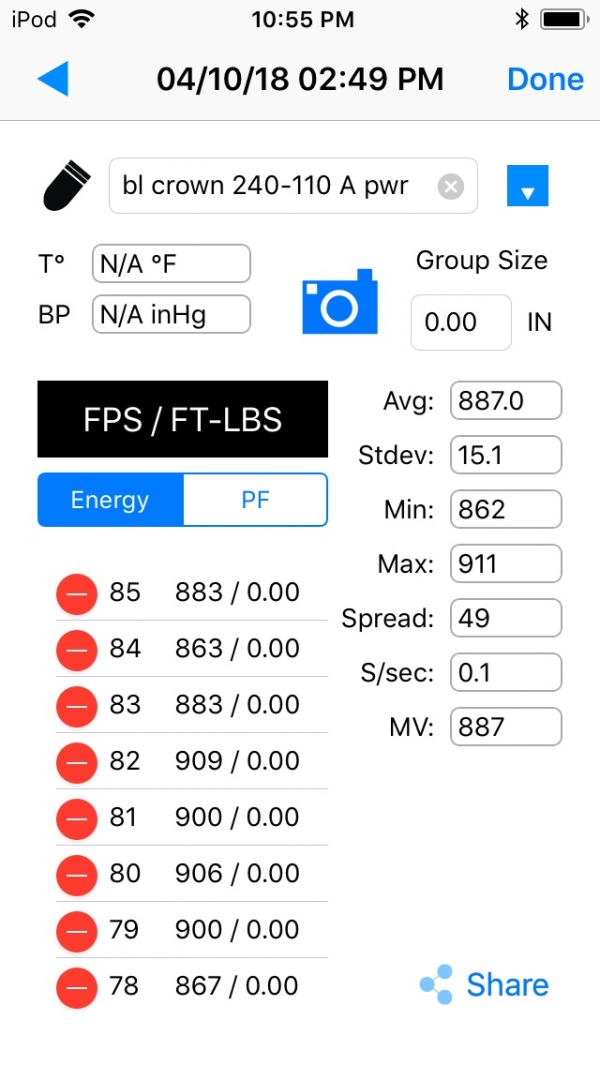

I deleted all the shots back to shot 85. (Yes, it re-calculates as I do this.)

ES went down only 3 fps and SD actually went up. I'll take off another 10...

Same numbers. Take off another 10...

Same numbers still!?

65 shots, SD of 14.5, and an ES of 49!? BTW, This is after a good 100 shots of break in.

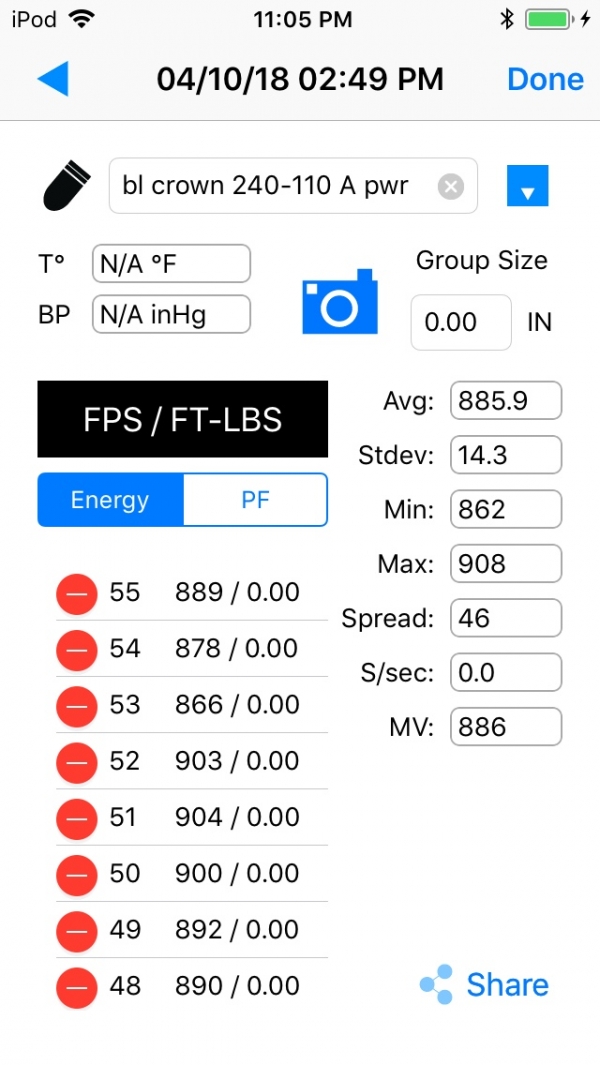

Take off another 10, maybe I'll start to see a difference...

I'm finally seeing a difference. But, not much.

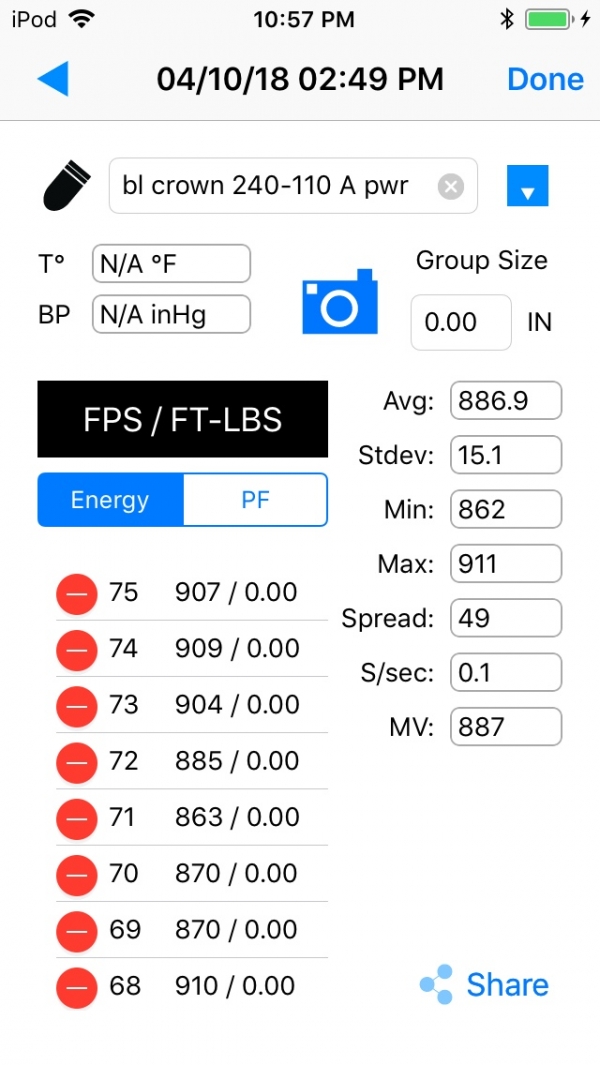

55 shots, SD of 14.3, ES of 46. I'd still expect better numbers than this. Also, does this show that I wasn't just falling off the reg?

Another 10...

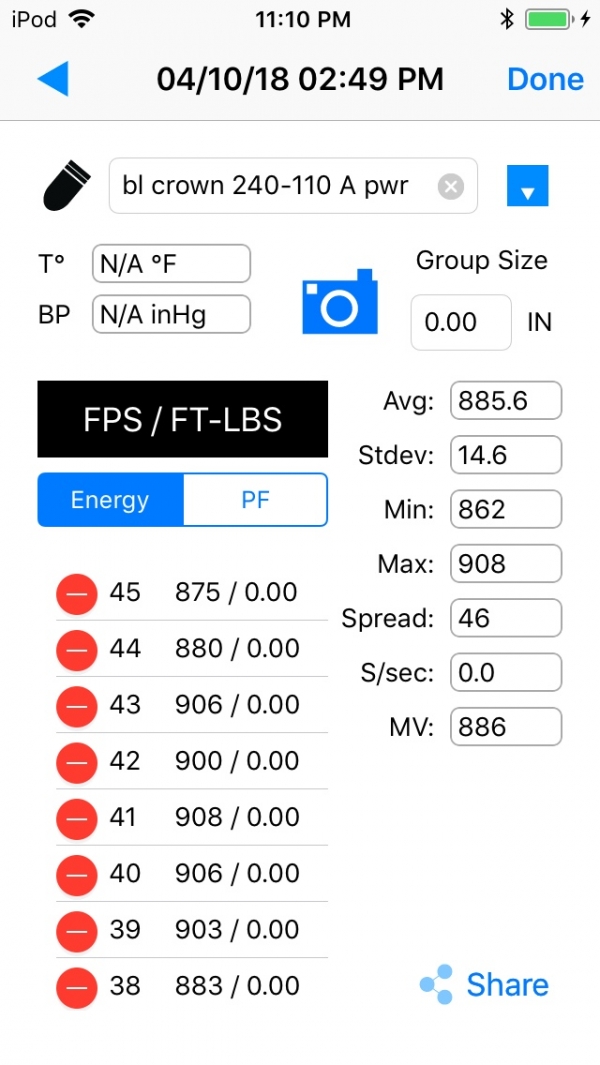

Worse? 45s, SD 14.6, ES 46

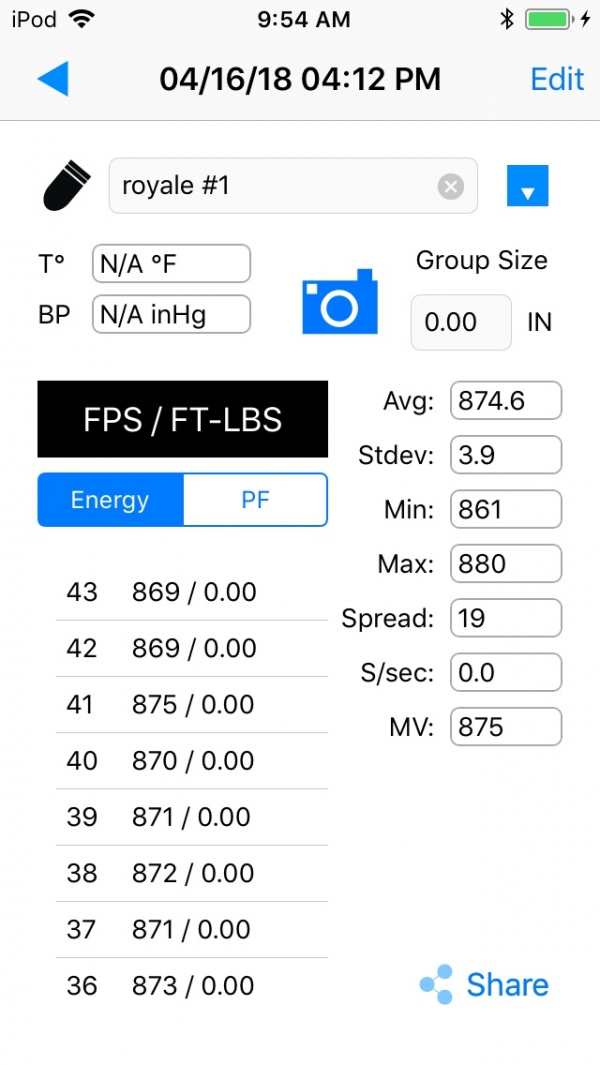

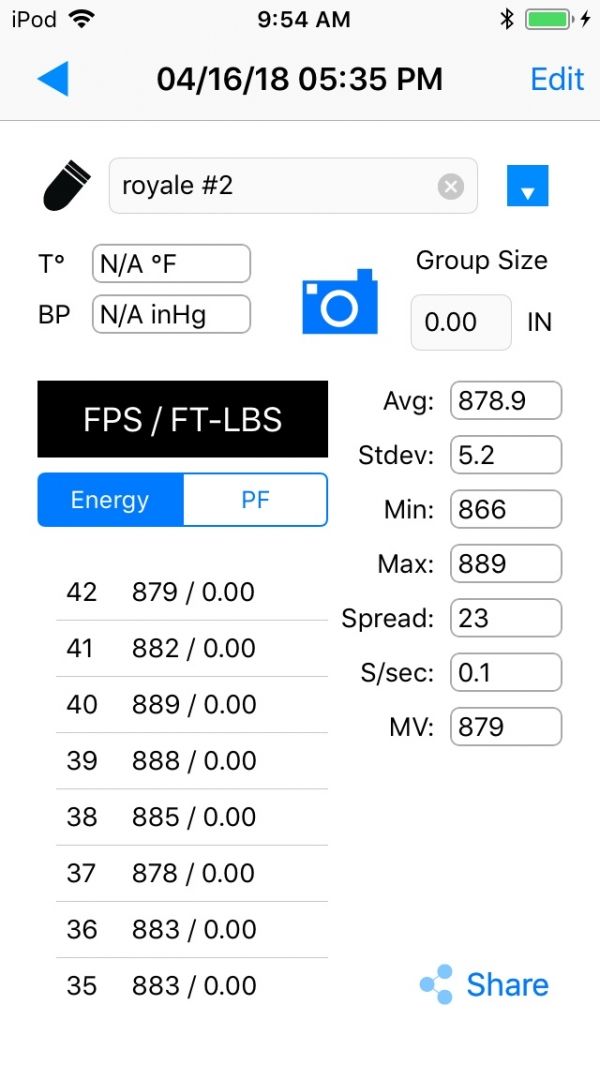

For comparison, I've got two shot strings from two different .22 Royales. Now... Admittedly, I've played around with Royales in the past, but I've never tuned either one of these. Royale #1 is my sweetheart and I can attest that it hasn't been touched since I bought it. Royale #2 I recently bought used with about 40 shots through it. The previous owner said it was shooting erratically and not performing well. No tuning to my knowledge.

Gotta love a Royale!

These should be comparable numbers now due to # of shots taken.

R#1 = 43s, SD 3.9, ES 19 Best

R#2 = 42s, SD 5.2, ES 23 Good

C#2 = 45s, SD 14.6, ES 46 WHAT!?!?

As I stated earlier, thank goodness these rifles were designed to be tuned by the shooter! This one's going to need it!

A CF bottle shooting a .25 around 880 should give more than 40 consistent shots. but, lets take off another 10...

Nah... what's the use? I could start screwing with the numbers in different ways but for what reason? And, to what end? Take off every shot that's not exactly (878) and I'll have a beautiful shot string but, it won't be a true story.

Overall, this rifle is beautiful but it is not happy with itself. I can't help but compare this to a Royale which (comparatively speaking) is a pain in the butt to tune but is coming out of the box shooting much more consistent.

Don't take this the wrong way guys, I know it sounds like I'm complaining here. Mostly, I'm not. I admit, I did expect more consistency out of the box but, I enjoy the tuning and learning. I just expected to screw it up more first, before bringing it back to a nice tune.

UPDATE: As you can see from the pics, these shot strings were taken yesterday. I have since fiddled around with some settings and am seeing my numbers improve. I did not shoot a string over the crony though since I was in the process of adjusting but I think the numbers are drastically improving. I may run a string tomorrow, if I have time.

The Crown, like the Impact, is an ongoing learning experience. Very soon, I'll be traveling and will have to put this all on hold.

As far as the picatinny rail goes, I found a solution and will expand on it some more soon. Happy to be off the sand bags!

Happy Shooting!

Tom... and Frank (he looks a little annoyed in this pic.)

I got my second Crown a couple weeks ago. Why did I get a second Crown? Well, that's a whole story I'm not going to get into right now. But I sure do miss Crown #1!

It's nice to se that they're coming with hard cases now. And, it's a nice case too. Granted, it's egg shell inside, but it's still a nice hard case.

Finally got the Blue Lam I've wanted since the first time I saw it. ?

I think it's cool how the blue hit "FX" just right.

Ah, Finally! A Crown specific instruction manual!

After a quick look over, it was time to get started with cleaning the barrel and taking "factory settings" pictures. I was surprised to see the reg set at 120b. I thought it would have been closer to 150b. No big deal to me, factory usually knows best.

After that, I got to work on seasoning the barrel and working towards getting the reg broken in. It doesn't take me long at all to be reminded of how much I dislike shooting off a dual sandbag setup. So... time to get to work installing a rail since these don't come with anything. I try to always have at least one spare picatinny rail in supply. I've been sitting on a rare "right hand" specific Royale stock that needs a rail on it as well. I figured, If I'm doing one, I might as well do both!

I tape up the area I'll be drilling and drawing on, to protect the finish of the stock and help prevent tearout.

Center and locate my rails where I want them. I like my rails to be as far forward as possible but still aesthetically pleasing. this is where I started to notice an issue.

I wanted to use T-nuts since the Crowns tongue is sooo thin. FX - Don't you think it's time to start adding some type of rail system to your stocks? Come on.

It looked fine on the bottom but, if I were to put it there, the T-nut would protrude past the edge on the top side. No good! This is why I measure twice and cut once. In "one-shot-only" cases like this, it's measure much more than twice before cautiously cutting.

Just move it back a little, right?

Nope. I'd be intruding on the gauge.

This is still a feasible option, though. I'd just customize the T-nut by cutting and edge. But, I still don't like it.

Back to the original location. If I move the screw back a little inside the oval shaped hole, I could secure the rail and have the T-nuts clear everything. Yahtzee?

2 Issues with this... A) If I locate the screw at the high point between two slots I lose BOTH slots because the screw is wider than the picatinny slot. If I locate it within the low area of the picatinny, I lose only that slot.

This might be personal preference....

B) If I put the screw within the first slot, It pushes my bipod back so far that there has to be a better option available. If I put it in the second slot it not only looks odd but, in reality, it pushes my bipod back to the third slot due to the tapered sides.

Spinning the rail around won't solve any of these issues either. So, I said "Screw it!" and decided to sleep on it and see if I could come up with another solution.

I still managed to get the Royale stock done though. I decided to tap the holes for this one since the stock tongue is a little thicker.

On to the next difficulty... Tuning.

One of the benefits of the Crown is its ability to be tuned by the shooter. Thank goodness! In this case, it needs it straight out of the box!

ES of 53? FX... I expected better than this.

Ok, Ok... Before you get into the "well, this" and "well that..."

Reg reading 120b, "A" power level, and I shot 110 shots from 240-110. So, it bumped up when it fell off the reg, right? I can accept that. It hit 915fps at shot #87 so, it's totally plausible.

I deleted all the shots back to shot 85. (Yes, it re-calculates as I do this.)

ES went down only 3 fps and SD actually went up. I'll take off another 10...

Same numbers. Take off another 10...

Same numbers still!?

65 shots, SD of 14.5, and an ES of 49!? BTW, This is after a good 100 shots of break in.

Take off another 10, maybe I'll start to see a difference...

I'm finally seeing a difference. But, not much.

55 shots, SD of 14.3, ES of 46. I'd still expect better numbers than this. Also, does this show that I wasn't just falling off the reg?

Another 10...

Worse? 45s, SD 14.6, ES 46

For comparison, I've got two shot strings from two different .22 Royales. Now... Admittedly, I've played around with Royales in the past, but I've never tuned either one of these. Royale #1 is my sweetheart and I can attest that it hasn't been touched since I bought it. Royale #2 I recently bought used with about 40 shots through it. The previous owner said it was shooting erratically and not performing well. No tuning to my knowledge.

Gotta love a Royale!

These should be comparable numbers now due to # of shots taken.

R#1 = 43s, SD 3.9, ES 19 Best

R#2 = 42s, SD 5.2, ES 23 Good

C#2 = 45s, SD 14.6, ES 46 WHAT!?!?

As I stated earlier, thank goodness these rifles were designed to be tuned by the shooter! This one's going to need it!

A CF bottle shooting a .25 around 880 should give more than 40 consistent shots. but, lets take off another 10...

Nah... what's the use? I could start screwing with the numbers in different ways but for what reason? And, to what end? Take off every shot that's not exactly (878) and I'll have a beautiful shot string but, it won't be a true story.

Overall, this rifle is beautiful but it is not happy with itself. I can't help but compare this to a Royale which (comparatively speaking) is a pain in the butt to tune but is coming out of the box shooting much more consistent.

Don't take this the wrong way guys, I know it sounds like I'm complaining here. Mostly, I'm not. I admit, I did expect more consistency out of the box but, I enjoy the tuning and learning. I just expected to screw it up more first, before bringing it back to a nice tune.

UPDATE: As you can see from the pics, these shot strings were taken yesterday. I have since fiddled around with some settings and am seeing my numbers improve. I did not shoot a string over the crony though since I was in the process of adjusting but I think the numbers are drastically improving. I may run a string tomorrow, if I have time.

The Crown, like the Impact, is an ongoing learning experience. Very soon, I'll be traveling and will have to put this all on hold.

As far as the picatinny rail goes, I found a solution and will expand on it some more soon. Happy to be off the sand bags!

Happy Shooting!

Tom... and Frank (he looks a little annoyed in this pic.)