Update:

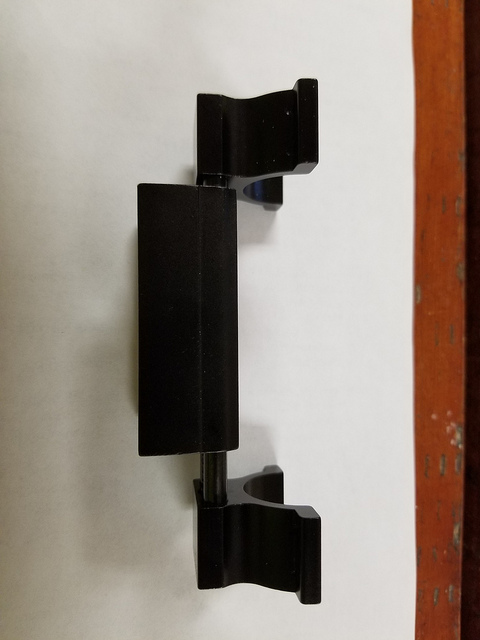

I just got home from work a little bit ago and unpackaged the ZR knock-off that I ordered. I won't add any extra photos because Insanity already covered that well. I can vouch that what I recieved in the mail today looks identical to what Insanity has posted of his. Here are some of my personal initial impressions and observations of this mount:

1. There is no branding anywhere on this mount. For my taste, that is not necessarily a bad thing.

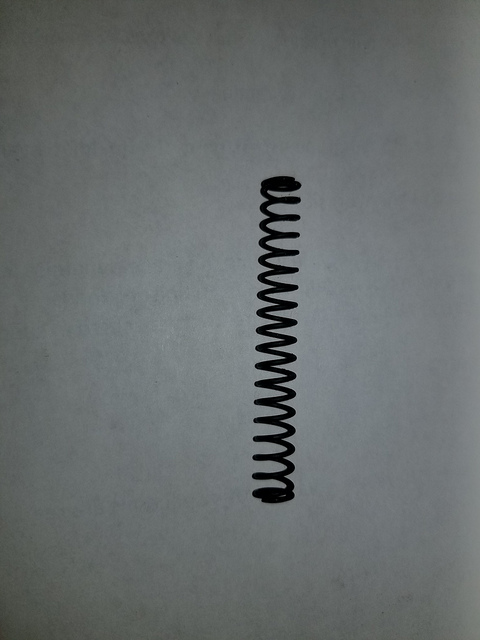

2. The spring on this mount "feels" like it has decent potential. It isn't hard to compress by hand, but it isn't weak either. It May have some real promise to it.

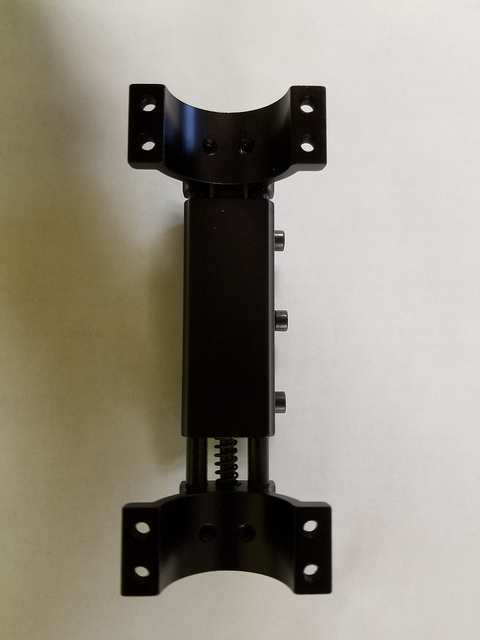

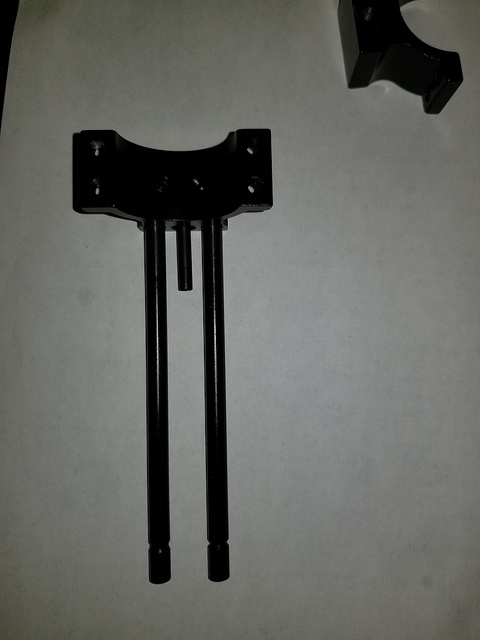

3. At first, I was a little concerned about the tie bars (rails). This mount came "assembled" (more on that in a minute), and the tie bars looked to have the same anodized coating on them as the rest of the aluminum did, which made me nervous about the manufacturer cutting some corners on this "cheap" mount. Once I disassembled it, I was pleasantly surprised to see that the tie bars are not anodized: Although a similar process, the tie bars are coated with a relatively smoothe black oxide finish, and with a small test I found that they are indeed made from hardened steel. There are also machined grooves 360-degrees around on both ends of each tie bar to catch the set screws for engagement at any radial point. I measured each quick with my calipers and they are identical in length at every reference point. This is good, no unexpected binding or unusual wear should be expected from that perspective. There was also a light, very thin coating of oil on the bars. It feels like a spray-on lube, not as thin as WD-40, but not thicker than a light air-tool oil. This is acceptable in terms of packaging and rust prevention, but in terms of functionality, there needs to be a thicker lube used here. More on that in a minute as well.

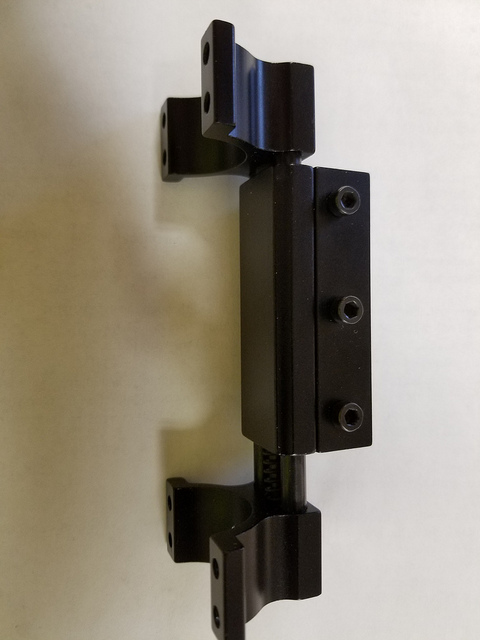

4. I found it interesting that the entire mount was assembled very loosely. Every screw for the top of the "rings" was loose as expected, but every set screw for the tie bars was engaged with the grooves of the tie bars, but was also very loose. It almost seems like when they loosely assembled and packaged this mount, that they fully expect the buyer to disassemble it to inspect it and "tune" it to their liking with a lube of choice? Maybe I am reaching a bit here, but I can't see how they would take the time to line everything up, run the set screws in far enough to engage the grooves in the bars, but not clinch anything down in the slightest. It just feels like they did this on purpose, which is fine with me, considering that my initial intentions were disassembly and inspection to begin with.

5. The packaging includes two different Allen keys, one for the 8 cap screws on top and the 3 mounting screws on the side, and a smaller Allen key for the 4 different set screws for the tie bars. For me, this isn't a big deal because I have more Allen keys than I can count, but for a buyer who may not own one size or the other, this is helpful.

6. The plastic reducers that are included adapt the 30mm aluminum ring pattern down to 1", and they also look just like the similar (or same) Diana rings. I like the idea of flexibility between sizes here as with the Diana mount.

7. The forward stop-pin also appears to be hardened steel and creates positive engagement with the mount for repeatable location. HOWEVER: Out of the box (just like the looseness of the set screws) this cannot be ignored. Just holding it my hand and compressing the mount into the spring and releasing it, the mount slams forward FAST and the lower mount contacts the hardened stop screw rather violently. I can only imagine that with the weight of a scope mounted, this would eventually indent the aluminum mount over time, potentially altering POI through the scope or worse. Again, a thicker lubrication than what is provided out of the box will be key here to slow the action down on it's return-travel forward.

8. There is some visually noticeable play between the tie bars and the mount. Now, it is not a huge difference, and I have not put my own preferred lube on this yet, which will undoubtedly shore things up quite a bit. And this is not necessarily a bad thing, as long as the forward-stop location proves to be repeatable after cycling. Like anything else with a geometry like this, location is not a deal-breaker, but repeatability will be.

9. I would rate the overall machining and mating of the parts here at a B+ or an A-. Everything looks very square and thought out relatively well from what I have seen. However, I would like to see just a LITTLE MORE tightness in tolerance between the tie bars and the base mount. However, this may change drastically as I work some different lube into it tomorrow.

10. There is no documentation included with the packaging, anywhere. It is literally two plain white boxes, no pamphlet, no branding, no frills. For me, I can live with that, but for a younger and/or inexperienced or unsuspecting buyer, this may be a problem if they do not have experience or foresight on what to possibly expect about how this was sent to them, which may lead to negative results if they tried mounting and using this thing as-is straight out of the box.

11. There is a stop-pin included in the base of this. This is probably my most negative take on anything mentioned here, and for four reasons. First, there are three screws that retain the side plate for the Weaver mount. The front and middle screws are 10mm length, and for the thread engagment that they have into the base, they are sufficient. However, the rear screw is at least 12mm in length. Instead of tightening into the mount base, it tightens through threads that are in the stop pin. See Insanity's photos above for a good visual of this.

This creates a small annoyance just to my eyes, because there is enough of a cant to the stop pin while tightening that brings it off-center while the rear mount screw is tightened. The tolerances between the outer dimension of the stop pin and the inner dimensions of the mount base are extremely loose, so one must be mindful of the order in which things get tightened here: The rear mounting bolt must be torqued first before the other two are so the stop pin is located and doesn't put stress or maring into the receiver.

Also, there is little wall depth between the threads of the stop pin and the outer circumference of the pin. Even if we assume that this is machined from hardened steel, from my experience I will tell you that it would not take much effort to split/crack the sides of this stop pin from a mild over-torque. This may be mitigated if the tolerances between the mount and the outer dimensions of the stop pin were tighter, but there is not enough room to stop the threaded area from failing and expanding. For that reason alone, I plan on putting this into a drill press (maybe a mill, depending on alignment with the mount, more on that in a moment) and opening the stop pin hole up from an M8 to a M10 threaded and hardened pointed set screw.

The included stop pin is "machined down" to dimensions much smaller than most stop pin grooves than I have seen in any receiver. Again, this is not acceptable. If a mount ever came loose, slop is your biggest enemy. A loose mount with a tight-fitting stop pin will at least give you a chance. A semi-loose mount with a loose-fitting stop pin will either break the stop pin from g-force, or cut a nasty gouge across the top of your receiver.

The Weaver-to-Picatinny adapter that was packaged here did not mate up with the stop pin of the Diana-style mount. Again, I am an avid DIY'er, but it irks me a little bit when a company offers to sell you something that is marketed as a potential necissity for compatibility, only to find out that what has been sent to you is not compatible. The outer dimensions of the stop pin were too large to engage the Weaver rail. Now granted, 40 seconds and a belt sander solves that problem for the stop pin, but to some young lads, this may be sonething not easily picked up on.

Conclusion:

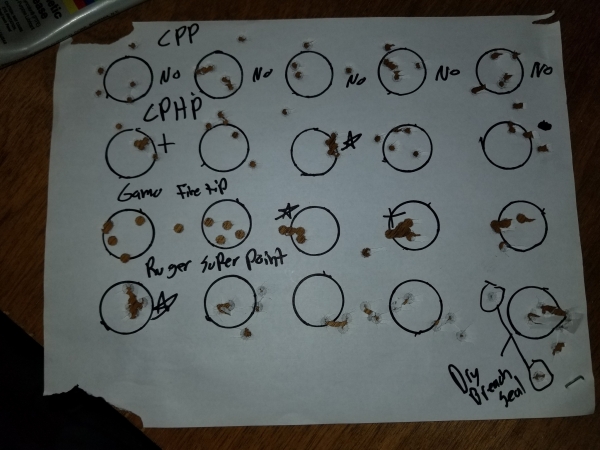

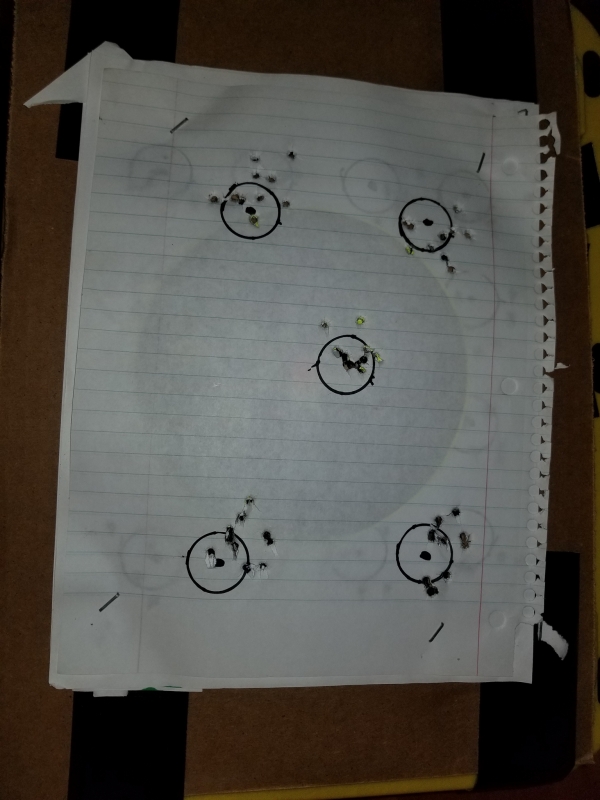

The jury is out until I send some shots downrange on paper with this. However, for a "$15 mount," I am somewhat impressed with what was shipped to me. After 20 years of working in engineering and preventative maintenance solutions, one thing I can say is that with a mechanical setup like this, a decent white lithium grease would be the best lubricant for this, possibly blended with a thicker moly paste. I do have a concern about the hardened forward stop screw, but I think I have also identified a solution to help suppliment this. But overall, for a $15 investment shipped (plus $7 for the low-profile Weaver-Picatinny adapter), I feel like there is some serious potential here.

I also feel like Diana either does not have that strong of a patent on their mount, or the company who is producing this one is getting around it with the slight design change with the Weaver mount... Or, they are selling this mount as a legit 100% rip-off and are going to ride it and make a few bucks until they get sued and disband themselves from it. But in my honest opinion, I can see how Diana is probably making $55 profit on their $63 price-tag, while this company is probably making $8 profit on a $15 sale. Having to use a 8mm Weaver-to-Picatinny adapter may be a deal-breaker for some, but spending the additional $50 for the Diana name may be a deal-breaker for others when there is little other difference to be mentioned. Just food for thought. Time will tell, I am looking forward to tinkering with it and seeing how POI stands up with it.

PT