G

Guest

Guest

As the title implies, I can't tap out the pin holding the end of the cocking lever to the breech block on my Remington 725VTR. It shares many parts with the Benjamin NPXL725. I used a roll pin punch and a small brick layers hammer, but cannot begin to make it move? It doesn't look welded, but it did have a round depression in the center of one end of the pin where it was pressed in? But it's in there brutally tight. Might need a gunsmith with a hydraulic press to remove it in order to install the front sling swivel?

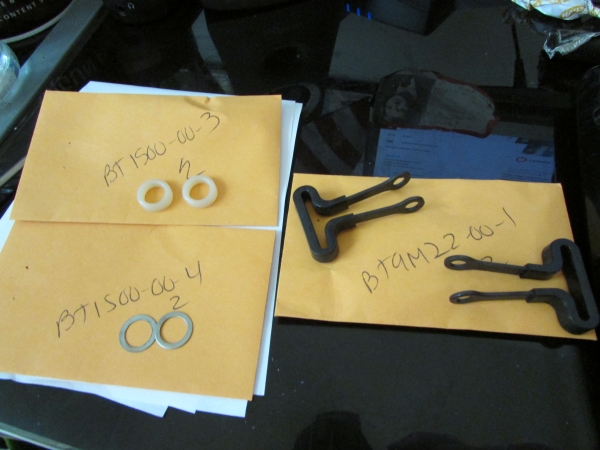

Really need a little help on this one? I wound up using a second shim on the breech seal to get a proper seal too. Just need to put a new seal in it. Again, parts from the NPXL725 fit great on this Remington 725VTR.

Really need a little help on this one? I wound up using a second shim on the breech seal to get a proper seal too. Just need to put a new seal in it. Again, parts from the NPXL725 fit great on this Remington 725VTR.