You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Can theses be fixed?

- Thread starter Oreida05

- Start date

You can try to tap it on a piece of wood, it may unstuck.

Either ball(s) or spring jammed the outer sleeve.

Good luck.

Either ball(s) or spring jammed the outer sleeve.

Good luck.

Upvote 0

Are you sure they are rated for the required pressure? All couplers and nipples are not necessarily rated for pcp. If they have failed/are damaged should that be telling you something?

Upvote 0

I will try spraying some WD40 to the inner side of the sleeve through the gap at the back end of the sleeve. Then put the connector on a piece of soft wood ( e.g. pine ) with the connector standing on it's front end ( where the balls are ). Then tap the back end ( the threaded end ) with another piece of wood and see if it can be loosen. Even if it can be de-frozen that way, you will need to take it apart to see what is causing the problem ( very likely the spring ) and judge whether it is still usable.

Upvote 0

3000-4500 PSI...No brainer chuck 'em and get new ones. Small pieces flying around, you might as well step outside in an F5 tornado.

Upvote 0

I see they are partial brass or maybe all brass with chrome plating. Brass is not rated for 4500 psi when the stainless ones are only rated to 5000 psi

Upvote 0

I see they are partial brass or maybe all brass with chrome plating. Brass is not rated for 4500 psi when the stainless ones are only rated to 5000 psi

Balderdash! From what source do you base this advice? Reputable companies like Best Fittings use brass in their product. My advice is if they are only seized because of a bit of grit, they should be serviceable. If there is any sign of bulging or shifting of the balls, scrap them.

Upvote 0

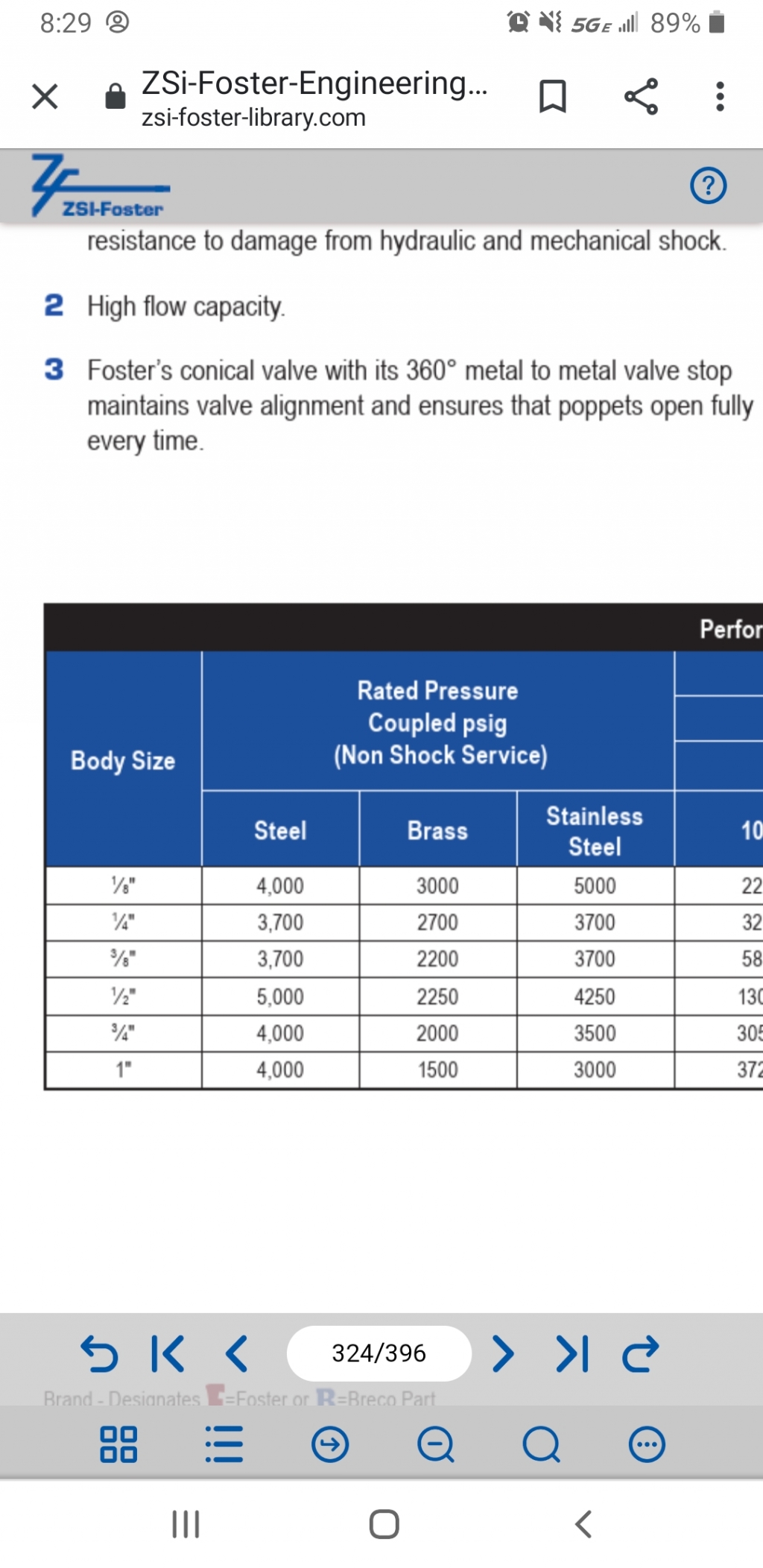

Here you go. Just common sense if you know anything about materials

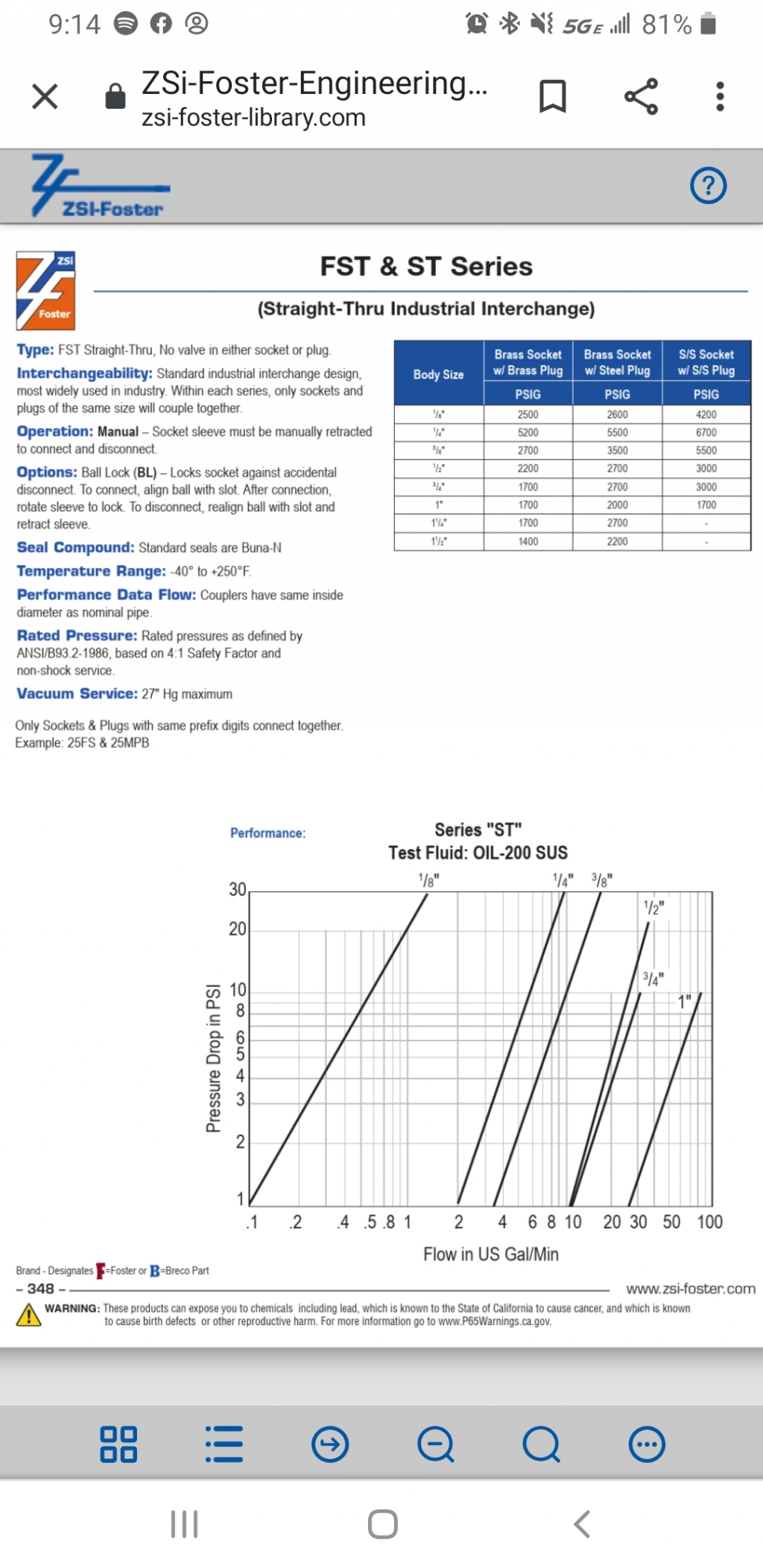

Can you say "Apples to Oranges"? Look at page 349 of that same catalog. Seems to me that the 1/4" body fitting in BRASS are rated to 5000psi.

The fitting in your pic has a check valve on the female side, I've NEVER seen a female foster in use in airguns that has a check valve.

https://zsi-foster-library.com/ZF-Catalog/?#p=349

Upvote 0

If people want to find out what happens when one blows apart fine. Know someone that was sold one that was brass but looked stainless from chrome plating. It ruined the hose and he said he was lucky he didnt get hit by the whipping hose

Upvote 0

Here is 348 that shows the ratings for 349. Brass is no where near the strength of the stainless and there rated at 5000 psi.

If people want to find out what happens when one blows apart fine. Know someone that was sold one that was brass but looked stainless from chrome plating. It ruined the hose and he said he was lucky he didnt get hit by the whipping hose

Are you saying the fittings (1/4) on page 349 are NOT rated for the 5200psi or 5500psi (depending on which male plug is used)? I mean you posted above....

I see they are partial brass or maybe all brass with chrome plating. Brass is not rated for 4500 psi when the stainless ones are only rated to 5000 psi

But then the manufacturer that you linked says it is. At least that's what I'm reading. Are you seeing something different?

Or are you making a blanket statement based on someone you know who apparently bought some junk?

Upvote 0

Those are 1/4" fitting. Not the 1/8" fitting we use. Who uses 1/4"

Who uses a Female Foster with a check valve in it? Like the link you posted?

BTW - If you want I can fine another brand, Parker, Best Fittings or other reliable brand it you'd like in 1/8". FACT is YOU stated that Brass was not rated to 5000psi. A Blanket statement with nothing to back it up.

Upvote 0

I don't know why you would want to argue about this. The OP shows a pic of a 1/8" foster. Why would you even bring up 1/4" fittings? Just to argue? This topic is about what we use, 1/8". I never said brass wasn't strong enough. It's not strong enough in are application.

I just got off the phone with foster engineer. The stainless are rated at 4200 psi. Just like it says. Brass are 2500 psi.

I just got off the phone with foster engineer. The stainless are rated at 4200 psi. Just like it says. Brass are 2500 psi.

Upvote 0

I don't know why you would want to argue about this. The OP shows a pic of a 1/8" foster. Why would you even bring up 1/4" fittings? Just to argue? This topic is about what we use, 1/8". I never said brass wasn't strong enough. It's not strong enough in are application.

I just got off the phone with foster engineer. The stainless are rated at 4200 psi. Just like it says. Brass are 2500 psi.

The way I see it is that YOU are the one arguing. YOU came on saying "Brass is not rated for 4500psi", but in reality there ARE Brass fitting, in 1/8" that ARE rated to 4500psi. And in the same respect you say that "Stainless are rated to 5000" and I have seen plenty of SS that are NOT rated to 5000.

Basically I'm saying use a RATED fitting whether it be brass, carbon steel or stainless steel. It seems to me, from reading your posts, that you are saying "Don't use Brass, use stainless".

Here is a fitting that appears to be very similar to the ones shown in the original post.

https://spaweapons.com/collections/high-quality-air-fittings-and-accessories/products/best-fittings-extended-quick-coupler-socket

Upvote 0

I find it hard to believe that those are rated at 5000 psi when the same fitting in steel is 4500 psi on the same website.

Brass yield is 19,600 psi and 316 stainless is 42,100. At half the strength how could it it be rated that high

I will leave it at that.

Brass yield is 19,600 psi and 316 stainless is 42,100. At half the strength how could it it be rated that high

I will leave it at that.

Upvote 0

I find it hard to believe that those are rated at 5000 psi when the same fitting in steel is 4500 psi on the same website.

Brass yield is 19,600 psi and 316 stainless is 42,100. At half the strength how could it it be rated that high

I will leave it at that.

You're using the #'s for regular 230 brass (Red Brass) . There are plenty of brass compositions that are way over that, and then you also have to add temper in.

Look at 330 Brass (low lead) which most tubing is made from, and then come back with those #'s for us. I'll help you out - Temper - Hard Drawn - Tensile = 75Kpsi and Yield 60Kpsi

Upvote 0