Hey fellas. I have been using 30 wieght silicone shock fluid from Amazon for awhile now for my pcp's and also handpumps. I got 12 ounces for like 20 bucks. Am I using the best kind of oil here? It works but I feel like a heavier wieght would make less mess or possibly last longer. I use divers grease for orings but what do you guys use for your hand pumps and pcp's? Also once a year I put a single drop in the foster fitting of my guns and let it lube up my valve and internals. It seems to work good but wonder what you guys think about that? It was kind of something I just did on my own. I thought it would keep my seals doing good. Thanks fellas.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Best silicone oil for pcp airguns?

- Thread starter Raden1942

- Start date

Silicone oils are a terrible lubricant ... only reason there used is having a VERY high flashpoint and Inert having little to no effect on rubber, plastics or leather etc ...

While it aids in assembly work used on o-rings and such, it is well known / acknowledged it does piss poor job of actually lubricating any sort of metal on metal parts or dynamic application unless some sort of rubber type seal running against a metal.

While it aids in assembly work used on o-rings and such, it is well known / acknowledged it does piss poor job of actually lubricating any sort of metal on metal parts or dynamic application unless some sort of rubber type seal running against a metal.

Upvote 0

Of course. I know that. I have never heard anyone offer any other product for pcp other than silicone. I am basically asking if there is a preferred brand or wieght. If there is some other product I should be using I've never heard of it. Isn't silicone like the only thing that won't detonate in a pcp?

Upvote 0

Scott - now that you slammed Silicone, can you answer the question. What is the best oil / lubricant?

Upvote 0

Krytox lubricants are used by some.

I think a VERY IMPORTANT fact within the USE of PCP's is spread around due to ignorance, having read what others repeat because those who read it previous did the same etc etc etc.

Compressing air CREATES HEAT and on the compressor side of things petroleum lubricants can be troublesome and why Silicone is used in many instances.

RELEASING already compressed air creates CHILLING and there is just shy of a snowballs chance in hell you could create a detonation issue within a PCP.

If you even could ? it would be upon ULTRA FAST FILLING which goes back to the COMPRESSION and Heat equation.

Personally assemble o-rings with silicone. Mechanical parts that are in dynamic use get petroleum oils or greases. Nearly all of them are outside of the HPA storage except for the valves poppet stem. Even Regulators internally I use a petroleum product to lubricate o-rings as well bevels because it is a DYNAMIC motion area and silicone's suck as lubricating !

I'm a professional tuner and the specific lubes used I keep proprietary ... I'm sure others will chime in on this thread and you will get many opinions on the subject.

Will say that LITHIUM base greases work very well and a little goes a long way. Triflow PTFE fortified synthetic grease another excellent one.

Scott S

I think a VERY IMPORTANT fact within the USE of PCP's is spread around due to ignorance, having read what others repeat because those who read it previous did the same etc etc etc.

Compressing air CREATES HEAT and on the compressor side of things petroleum lubricants can be troublesome and why Silicone is used in many instances.

RELEASING already compressed air creates CHILLING and there is just shy of a snowballs chance in hell you could create a detonation issue within a PCP.

If you even could ? it would be upon ULTRA FAST FILLING which goes back to the COMPRESSION and Heat equation.

Personally assemble o-rings with silicone. Mechanical parts that are in dynamic use get petroleum oils or greases. Nearly all of them are outside of the HPA storage except for the valves poppet stem. Even Regulators internally I use a petroleum product to lubricate o-rings as well bevels because it is a DYNAMIC motion area and silicone's suck as lubricating !

I'm a professional tuner and the specific lubes used I keep proprietary ... I'm sure others will chime in on this thread and you will get many opinions on the subject.

Will say that LITHIUM base greases work very well and a little goes a long way. Triflow PTFE fortified synthetic grease another excellent one.

Scott S

Upvote 0

I'm not sure how silicone became so widely accepted (in error) as the best lubricant for anything related to PCP air rifles. Silicone is okay to lightly lube O rings when assembling in a static application. When used in metal-on-metal in a high pressure application, it can actually cause seizing, and should be avoided. I'm no metallurgist (nor professional tuner), and there are many good lubricants available for all applications, to the point of confusion. I have found, for a very small price, you can buy a lifetime supply of two lubricants that can be used with good results in almost any metal-on-metal application, Mobil One synthetic oil, and grease. I'm sure there are many very good petroleum based lubricants, but here is what swayed me in favor of synthetics, summarized from lubricant industry information. It seems that petroleum-based oils incorporate molecules of hydrocarbons as well as additives such as paraffin, salts, and metals. Each of these molecules have slightly different reactions to heat, moisture and oxygen. These additives sometimes comprise as much as 25 percent of the oil’s formulation depending on the manufacturer. Synthetic lubricant bases contain no sulfur, metals or phosphorus, which makes synthetic oil more thermally stable than petroleum oil. So, each to his own. For a few bucks, a quart of Mobil One oil and grease will, best as I can estimate, last about 10 life times. I have not found a firearm or air rifle application in which one of these does not work very well.

Upvote 0

I have a nomad ii compressor and does that mean that I should stop using silicone as a lubricant and switch to a synthetic like mobil 1??

hegshen

hegshen

Upvote 0

I use radio control car silicone shock/diff oil. Really good stuff. You can get it in different weights as well. If I use grease I just use the divers stuff.

Upvote 0

https://www.movingupgaragedoors.com/lubriplate-l0034-094-motor-assembly-grease?_vsrefdom=adwords&gclid=EAIaIQobChMIgfD9hsrQ6AIVBh6tBh08owohEAQYASABEgJATvD_BwE#

can anyone give me their opinion on Lubriplate assembly grease? Always wondered about this stuff, especially in areas with threads such as air tube end caps.

can anyone give me their opinion on Lubriplate assembly grease? Always wondered about this stuff, especially in areas with threads such as air tube end caps.

Upvote 0

I thought silicone divers grease was safe to use. YO!

As Scott described, it's usually not a matter of safety, silicone is just a poor metal-to-metal lubricant. If you use it in an application that has little heat or pressure, it's probably okay, since that application usually doesn't need much lubrication anyway. The risk involves heat and pressure. A rifle maker told me of instances where connections such as the air bottle or adapter were seized in place because the owner used silicone on the threads.

Upvote 0

For metal to metal, like trigger mechanisms use grease. For compressors use a compressor specific lubricant. I've used FP10 to lube pellets and protect the finish of my airguns for years with no I'll effects.

Upvote 0

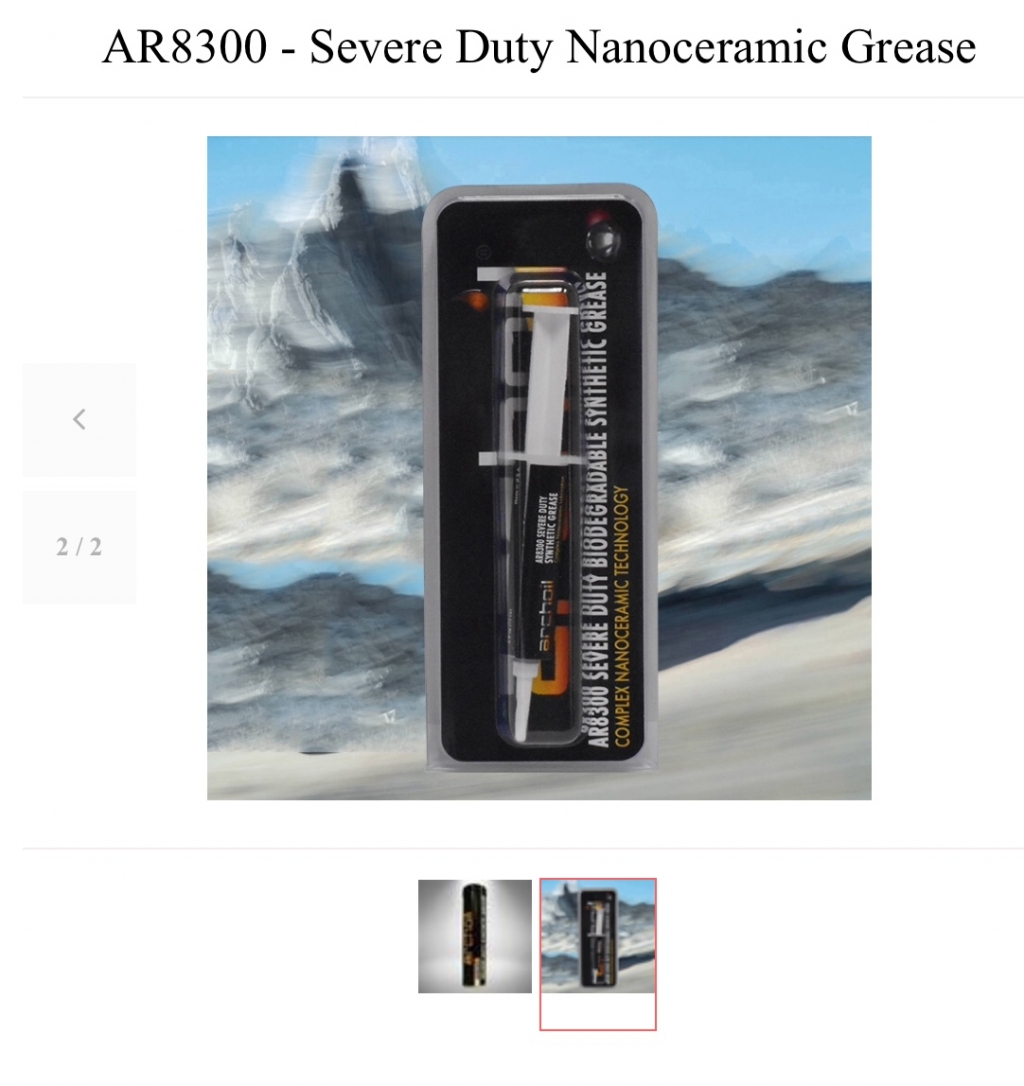

I have used the below for years now. AR 8300 on metal to metal or moving stuff external to the air reservoir and Superlube on all orings. I am not a lube Engineer. Just sharing what I use with good results.

Upvote 0

Bigragu lubriplate works insanely well on moving parts that are in contact with water. I use it on my m1 garand and it's designed to be used firing tons of rounds in the rain or in the ocean or whatever and it takes high heat. There are better greases made today as far as lubricant such as common high temp vehicle grease at Walmart or autozone. I love the lubriplate for my garand but probably not the best for airguns.

Upvote 0

I used to lubricate the the barrel on my impact, where the loading block is, with silicone grease. I then noticed the loading block scratched off the black finish on the barrel. I then switched to grease, and all was fine. So yes silicone oil is bad on metal against metal. So now I use grease on even the barrel O-rings, when I switch barrels. But I would not use it on O-rings inside the pressure chamber, just in case. Silicone oil can work as pellet lube though.

Upvote 0

I have a nomad ii compressor and does that mean that I should stop using silicone as a lubricant and switch to a synthetic like mobil 1??

hegshen

I do not know about that specific compressor, but if you use silicone oil to lubricate the moving parts like pistons, it sounds like a very bad idea to me. I would use the recommended oil by the manufacturer (or one with similar properties), and that would normally be some kind of compressor oil. You can use silicone on the fill hose O-rings if you like, as there is no moving parts there.

Upvote 0

The problem with professional tuners telling us to use unknown petroleum lubes is that many rubber and plastic parts melt when exposed or soaked in oils. Even if the actual oil is fine with most O-rings, it may still melt with a carrier solvent. So moving away from silicone oil without a safe alternative is just bad advice.

I have many years experience with motorcycle suspension and bicycle suspension and I have seen well known brands of motorcycle fork oil melt internal parts of bicycle forks. The worst of which was a White Bros fork that had a bottom out bumper melted into a pudding state. Some bicycles used the same bumpers as the main springs.There are at least 5 different materials that O-rings are made from, some resist solvents, but have other issues at high pressure.

I have many years experience with motorcycle suspension and bicycle suspension and I have seen well known brands of motorcycle fork oil melt internal parts of bicycle forks. The worst of which was a White Bros fork that had a bottom out bumper melted into a pudding state. Some bicycles used the same bumpers as the main springs.There are at least 5 different materials that O-rings are made from, some resist solvents, but have other issues at high pressure.

Upvote 0

On threaded end caps of a pressure tube, it relies on an inner o ring seal to seal air pressure We all know that. But we also know the silicone oil or grease we apply on the o ring will get onto those threads somehow which cause them to seize up. Will copper anti seize work on those threads in that application?

im starting to make a habit in using copper anti seize on air gun fasteners that tend to get removed more often than others, as I have either rounded off allen head sockets, or snapped them altogether.

Raden, yes, I’ve always wondered about Lubriplate assembly lube in firearms and Airgun use. It doesn’t take much do do it’s magic. That stuff works awesome. I first used it when I had to replace the crankshaft thrust bearing on my 1993 Cummins diesel. While I was under the truck doing this with engine in place, I went ahead and changed out all the crankshaft bearings along the with piston rod bearings. I thought one tube wouldn’t be enough, but I still have plenty left.

im starting to make a habit in using copper anti seize on air gun fasteners that tend to get removed more often than others, as I have either rounded off allen head sockets, or snapped them altogether.

Raden, yes, I’ve always wondered about Lubriplate assembly lube in firearms and Airgun use. It doesn’t take much do do it’s magic. That stuff works awesome. I first used it when I had to replace the crankshaft thrust bearing on my 1993 Cummins diesel. While I was under the truck doing this with engine in place, I went ahead and changed out all the crankshaft bearings along the with piston rod bearings. I thought one tube wouldn’t be enough, but I still have plenty left.

Upvote 0

Have any of you guys ever tried Nano-Oil? Something I've used on steel moving parts for a long time. It has a magnetic component that measures 0.09 microns to get into and stick in the microscopic crevices.

Upvote 0

maybe not necessary air guns,butt among the best is BOESHIELD T-9..."take it to the bridge...anyhow I use fishing reel lubricants I like Quantum Hot Sauce,SpeedX .good enough for my reels good enough for my guns...

Upvote 0