It's that time of year again when all my other projects take a back seat. I have the unique privilege of making the trophies for the Extreme Benchrest Competition. They were very well received at last years EBR as well as EBR Mexico. This year, I thought I'd bring you all along for the process and some sneak peeks.

Just outside the Tomcat Airguns filming/shooting room is the remainder of a busy 30x40 shop. This is where I spend a lot of my time DIY-ing, performing vehicle maintenance, experimenting, and woodworking. Before I can even start, I have to clean up the leftovers from a busy shop and a busy life. (The "busy life" part is just another way to say, "I'll pick it up later." lol!) These pic were taken after about 3+ hours of cleaning! I actually filled a 55 gallon drum full of sawdust!

Welcome... to Tomcat Woodworking!

This side of the shop is set up for cutting, shaping, and glue up.

Some of my clamps. The saying is true... you can't have too many clamps.

Table top sander, CNC, laser, and tabletop planer.

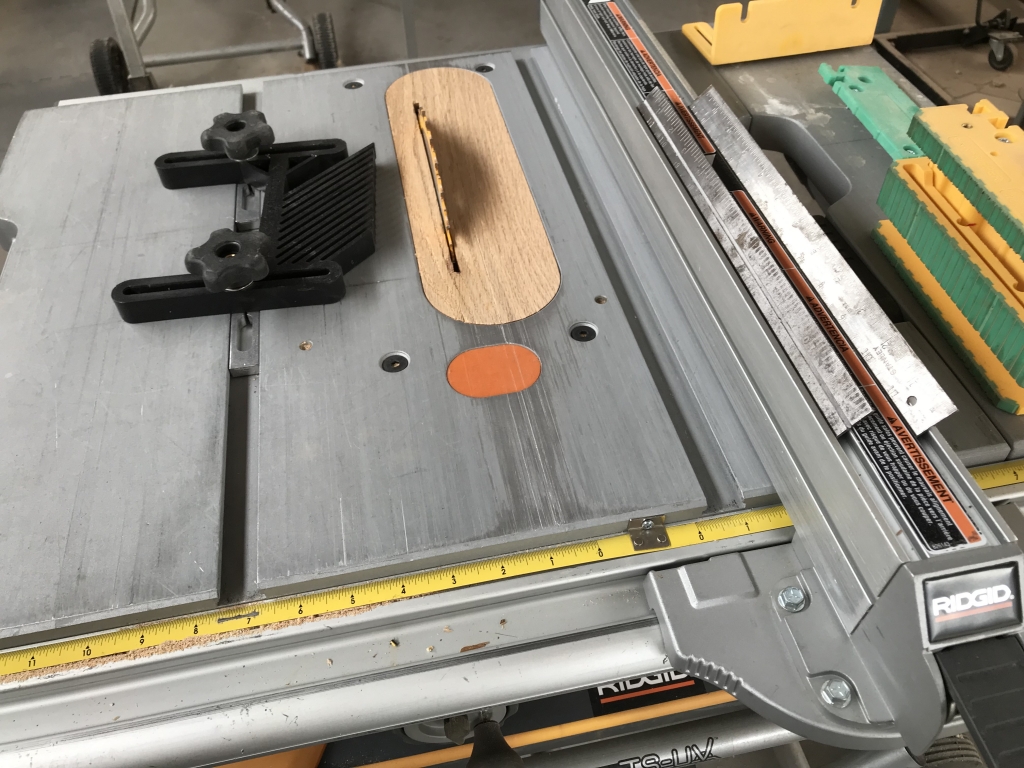

This is the router station that I built. I've got a dedicated router under that table extension. When not in use, I can flip it up and out of the way.

It's VERY RARE to see either one of these saws in this clean of a condition!

I wasn't able to get to cleaning the whole shop as you can tell by my sanding station. I'll be cleaning that up later on today. I use a lot of different tools when making these trophies but, it all comes down to the sanding to get the smoothness and finish right. I'll do bulk sanding on the tabletop sander, fine sanding with the twin RO sanders, and final sanding by hand. Yeah... I hand sand each trophy and yeah, hand sanding sucks. For me, making these trophies is a way for me to show how much I love the sport of air gunning and when the hand sanding starts to suck, I just think about the shooter that will be receiving it and it keeps me going. On the right side of the pic, you can just make out the back side of my rubber mulch shot box still on the bench top from some chrony work.

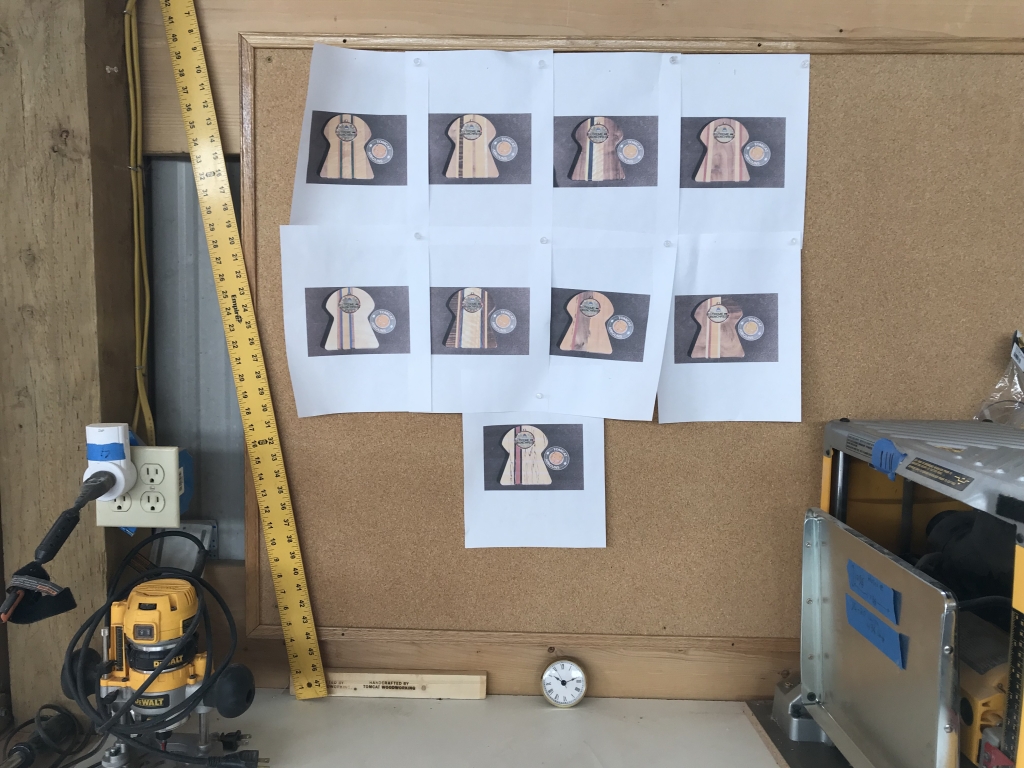

My inspiration wall.

LUMBER!!

I collect exotic hardwoods throughout the year for this project more than any other unique woodworking projects I take on. I also keep an eye out for unique woods from other resources. Believe it or not, I have found some very stunning wood inside chunks of firewood. On the list of woods... walnut, maple, curly maple, thermally modified curly maple, mahogany, beli, wenge, lati (white wenge), red heart, yellow heart, purple heart, bamboo, bloodwood, black palm, red palm, patagonian rosewood, canary wood, cherry, oak, bubinga, silver leaf poplar, sycamore, zebra wood, ash, leopard wood, marble wood, spalted maple, spalted tamarind, bocote, and more. There's some that I don't even know what they are! This is most of my hardwood and exotics collection but, there's even more that I'm didn't take pics of. I'd say I'm somewhere in the neighborhood of 4K in hards & exotics.

And, Laminates!! Working with hardwoods and exotics is hard enough but, laminates can be extremely challenging!! I use them because they seem to be the easiest way to get the most vibrant and unique colors such as blue, aqua, green, orange, wine, olive, and so on.

I've actually laminated laminates in order to get the color combination I was looking for. I don't ever want to do that again!

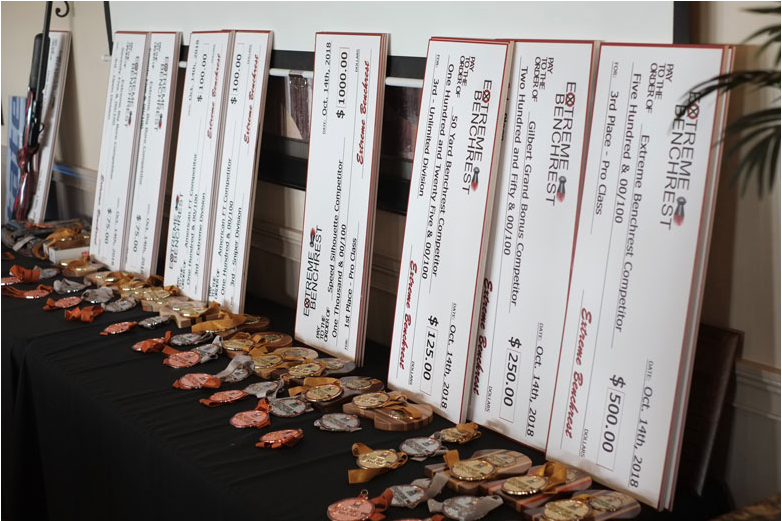

Here's some pics from the Hard Air Magazine article from last years Extremem Benchrest showing the winners receiving their prizes.

Michael Wendt starting his collection.

Michael Wendt growing his collection! LOL! Way to go Michael!

Here's Claudios trophy. This one was a lot of work! The center is actually unknown but, I think it's a flame birch or flame maple. The two layers of laminates were very difficult to make. I had to cut each of them on an angle, flip the pieces, glue them back together, square them off, and then cut them to size. It was a lot of work for those 4 little strips of wood! After those is some bamboo and the outsides are thermally modified dark curly maple which is a softer wood that chips very easily but smells wonderful when working with it. It's almost like a chocolate-coffee smell.

Some of you may know that I sell clocks and mini pellets using this design. What may not be as well known is that the trophy pellets are a certain size which is smaller than the clocks, and bigger than the mini's. It's a size that I will never sell to anyone. The only way to get that particular size is to win it at the Extreme Benchrest Competition! I hope to see you there!

Happy Shooting!

Tom

Just outside the Tomcat Airguns filming/shooting room is the remainder of a busy 30x40 shop. This is where I spend a lot of my time DIY-ing, performing vehicle maintenance, experimenting, and woodworking. Before I can even start, I have to clean up the leftovers from a busy shop and a busy life. (The "busy life" part is just another way to say, "I'll pick it up later." lol!) These pic were taken after about 3+ hours of cleaning! I actually filled a 55 gallon drum full of sawdust!

Welcome... to Tomcat Woodworking!

This side of the shop is set up for cutting, shaping, and glue up.

Some of my clamps. The saying is true... you can't have too many clamps.

Table top sander, CNC, laser, and tabletop planer.

This is the router station that I built. I've got a dedicated router under that table extension. When not in use, I can flip it up and out of the way.

It's VERY RARE to see either one of these saws in this clean of a condition!

I wasn't able to get to cleaning the whole shop as you can tell by my sanding station. I'll be cleaning that up later on today. I use a lot of different tools when making these trophies but, it all comes down to the sanding to get the smoothness and finish right. I'll do bulk sanding on the tabletop sander, fine sanding with the twin RO sanders, and final sanding by hand. Yeah... I hand sand each trophy and yeah, hand sanding sucks. For me, making these trophies is a way for me to show how much I love the sport of air gunning and when the hand sanding starts to suck, I just think about the shooter that will be receiving it and it keeps me going. On the right side of the pic, you can just make out the back side of my rubber mulch shot box still on the bench top from some chrony work.

My inspiration wall.

LUMBER!!

I collect exotic hardwoods throughout the year for this project more than any other unique woodworking projects I take on. I also keep an eye out for unique woods from other resources. Believe it or not, I have found some very stunning wood inside chunks of firewood. On the list of woods... walnut, maple, curly maple, thermally modified curly maple, mahogany, beli, wenge, lati (white wenge), red heart, yellow heart, purple heart, bamboo, bloodwood, black palm, red palm, patagonian rosewood, canary wood, cherry, oak, bubinga, silver leaf poplar, sycamore, zebra wood, ash, leopard wood, marble wood, spalted maple, spalted tamarind, bocote, and more. There's some that I don't even know what they are! This is most of my hardwood and exotics collection but, there's even more that I'm didn't take pics of. I'd say I'm somewhere in the neighborhood of 4K in hards & exotics.

And, Laminates!! Working with hardwoods and exotics is hard enough but, laminates can be extremely challenging!! I use them because they seem to be the easiest way to get the most vibrant and unique colors such as blue, aqua, green, orange, wine, olive, and so on.

I've actually laminated laminates in order to get the color combination I was looking for. I don't ever want to do that again!

Here's some pics from the Hard Air Magazine article from last years Extremem Benchrest showing the winners receiving their prizes.

Michael Wendt starting his collection.

Michael Wendt growing his collection! LOL! Way to go Michael!

Here's Claudios trophy. This one was a lot of work! The center is actually unknown but, I think it's a flame birch or flame maple. The two layers of laminates were very difficult to make. I had to cut each of them on an angle, flip the pieces, glue them back together, square them off, and then cut them to size. It was a lot of work for those 4 little strips of wood! After those is some bamboo and the outsides are thermally modified dark curly maple which is a softer wood that chips very easily but smells wonderful when working with it. It's almost like a chocolate-coffee smell.

Some of you may know that I sell clocks and mini pellets using this design. What may not be as well known is that the trophy pellets are a certain size which is smaller than the clocks, and bigger than the mini's. It's a size that I will never sell to anyone. The only way to get that particular size is to win it at the Extreme Benchrest Competition! I hope to see you there!

Happy Shooting!

Tom