An Air Odyssey

Well, I am in the middle of a fun little project replacing O-Rings, installing an Altaros Regulator and performing a layman's tune on my AAS510 Extra (Inspired by Matt Dubber). I want to stress that although I have rebuilt several PCP's, most of what I post here is experimental and not based on technical knowledge. I will be posting my progress and results of short-stroking this air-arms S510 air rifle on the slim chance someone is interested.

To begin, finding exact O-ring sizes online for this rifle and certain others for that matter seems to be hit and miss or top secret. So, after extensive research and taking my own measurements, I finally came up with an easy to read O-ring chart containing the different sizes needed to rebuild an AirArms Model S410 & S510 (link to chart below). PyramydAir carries an O-ring kit, but note that it is only for the bottom end. Full service kits are available from the UK, but it's a longer wait and runs the risk of getting stuck or lost at Customs. In the end, ordering from theoringstore.com was the logical choice for me.

Link to O-Ring size chart for AirArms S510 https://flic.kr/p/W9NeTW

Link to Parts List for AirArms S510 https://flic.kr/p/W9NfgQ

O-ring size chart .Pdf https://drive.google.com/file/d/0B5Nu6UixbtYRR011R1VDRnJxUGM/view?usp=sharing

I won't bore you with the rebuild itself or the Altaros Regulator install in this post, but here is a link to a very long comprehensive video of the AAS510 tear-down, regulator install and O-ring replacement if interested. The video also includes shroud removal and O-ring change on the inner barrel tube support which is Important for accuracy.

https://youtu.be/HQAfyI6qSqA

The rifle I am working on is an AAS510 Extra FAC in .22cal.

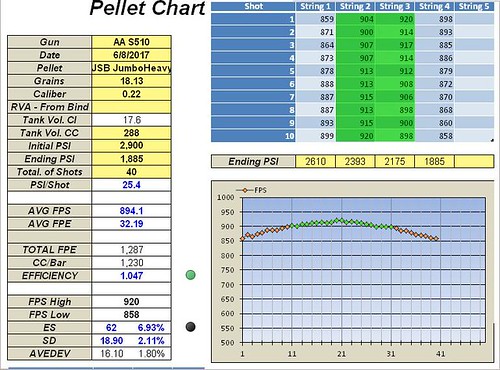

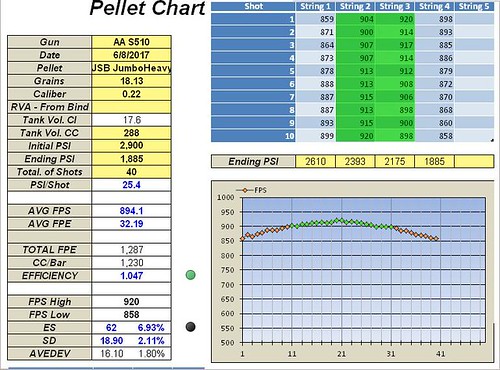

Before making any changes to the rifle, I filled it to the factory recommended 200Bar (2900psi) and put 40 shots down the barrel using JSB Jumbo Heavy 18.13gr over the chronograph before installing the regulator. That gave me a baseline for the tune and a realistic idea of what to expect from the rifle after the regulator install. Pellet Chart below shows results. Rifle averaged 894fps at 32.19fpe. End pressure was 1885psi. That is about 25.4 psi/shot with an ES of 62

Only 18-20 shots in the 20ES range.

40 shots Pre Regulator, Stock Hammer Spring 61.97mm, Stock Hammer

Based on these results, I have set a goal to achieve at least 40 shots at 30fpe on a 200Bar fill (2900psi) using JSB Jumbo Heavy 18.13gr with an ES of 20 or under.

The Altaros regulator was then installed while retaining the original valve spring, hammer and hammer spring. I did not change the factory settings on regulator. It is as I received it.

The reason I went with the Altaros brand is the fact there is no drilling the cylinder and the gauge will still read cylinder pressure after installation.

Regulator screw position as set from factory

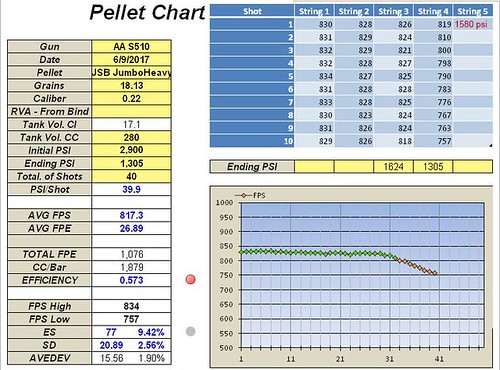

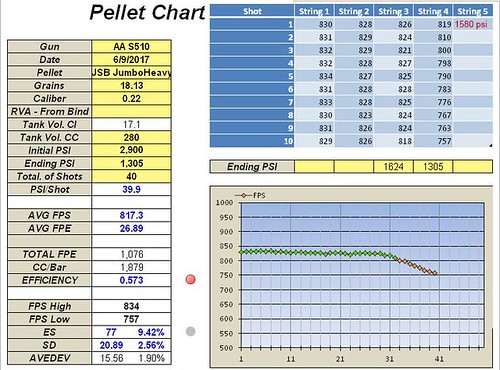

After shooting over the chronograph it appears the regulator was set to 110Bar+-. Pellet Chart below shows the result of 40 shots from a 200Bar (2900psi) fill down to 90bar (1305psi) for an average of 817fps at 26.89fpe. That’s about 39.9 psi/shot with an ES of 77. As expected, it is using a bunch of air and the specs are well under my objective.

Regulator 110Bar, Stock Hammer Spring 61.97mm, Stock Hammer

To reduce air consumption, I had a choice of cranking up the regulator to help balance out the heavy hammer and spring, replacing the valve spring with a heavier one, turning the hammer down to remove some weight or maybe shorten/lighten the hammer spring. Given the fact that I was only getting 817 fps average, I decided to adjust the regulator first and leave everything else as is for now. I turned the screw on the regulator counter-clockwise (as per Altaros online instructions) until it reached the red mark (Maxed out I think). Altaros claims it should be around 150Bar at the red mark.

Regulator set to max

Put the rifle back together and test fired over the chronograph.

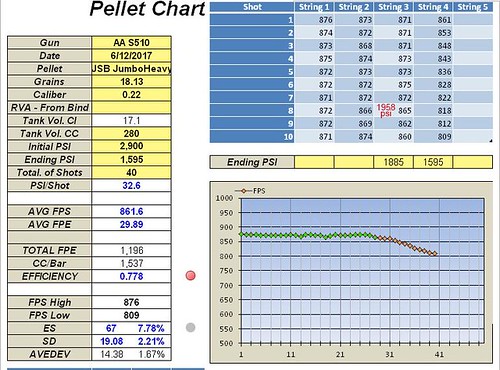

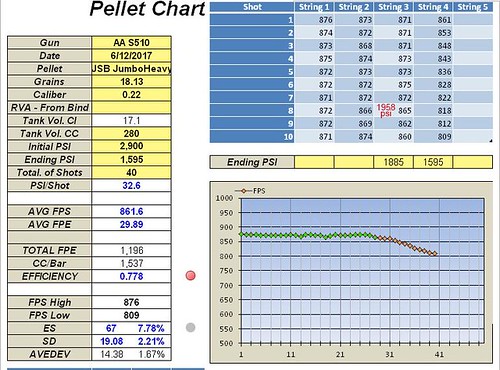

She got 28 shots on the regulator. Pellet Chart below shows a 40 shot string from a 200Bar (2900psi) fill down to 110bar (1595psi). It had an average of 862fps at 29.89fpe with an ES of 67. That is 32.6 psi/shot. Bad news is that the regulator is maxed out at 135Bar. Better news is that I reached my FPE and ES goal within those 28 regulated shots. It’s now time to work on that shot count.

Regulator 135Bar, Stock Hammer Spring 61.97mm, Stock Hammer

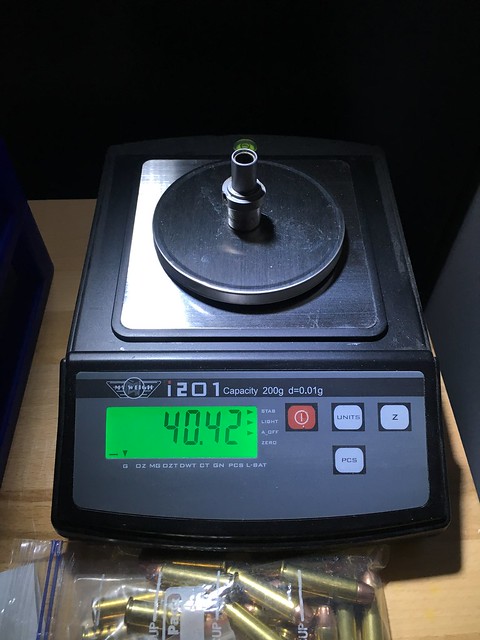

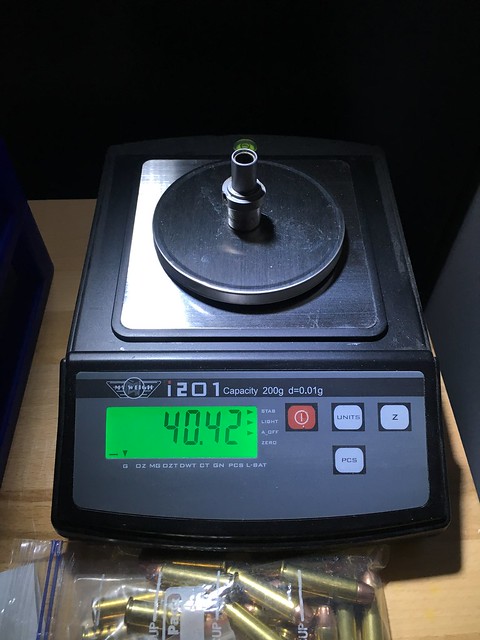

Next step....I decided to remove some weight off the hammer. Factory hammer weight was 49.59 grams. I turned it down a little and ended up with a weight of 40.42 grams. I do not have a lathe so I improvised using a drill press, die grinder and a couple files. Check out video link if interested in that Red-neck technique.

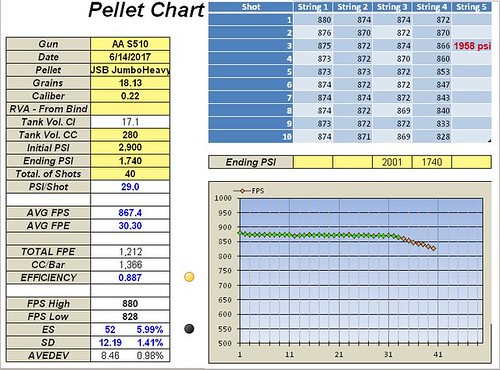

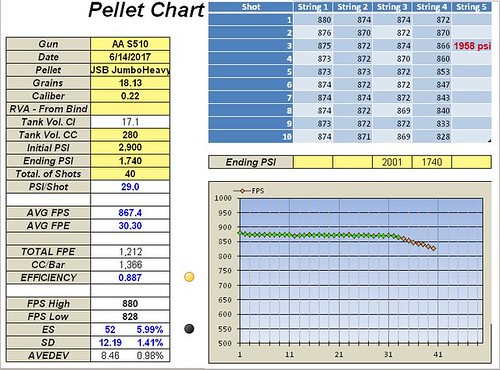

I then installed the lighter hammer leaving everything else as is. Test fired over chronograph again. Pellet Chart results are shown below. Rifle was getting 33 shots before falling off regulator. 40 shots averaged 867fps at 30.30fpe with an ES of 52. Now it is using 29 psi/shot. I did not lose any velocity but gained 5 shots. Getting closer to my goal. Now time to shave the hammer a bit further to save a little more air.

Regulator set at 135Bar, Stock Hammer Spring 61.97mm and Hammer lightened to 40.42grams

Back to the drill press and took a few more grams off the hammer. It is now down to 37.81grams.

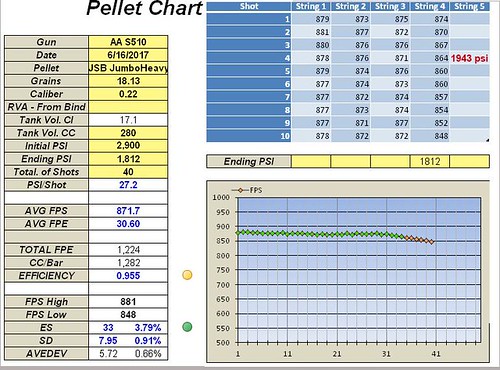

Installed lighter hammer and fired 40 pellets over chronograph again.

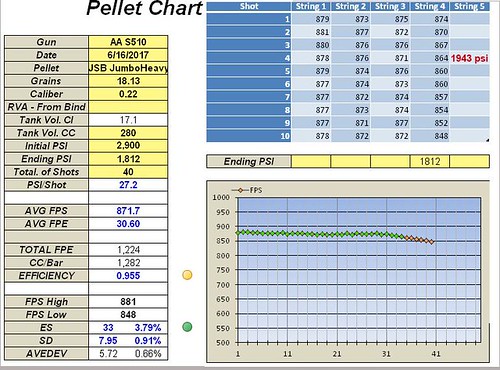

Chart results posted below, but not much change. I gained maybe one shot for a total of 34 shots before falling off reg. Interesting thing though, I noticed when it falls off the regulator the velocity does not drop as fast. Around 20fps higher at shot 40, making the shots 35-40 curve a little flatter. Rifle averaged 871fps at 30.60fpe with an ES of 33. Air consumption is now 27.2psi/shot.

Hmmmmmmm.......I expected better results.

Regulator set at 135Bar, Stock Hammer Spring 61.97mm and Hammer lightened to 37.81grams

At this point I debated which direction to go. I needed to use less air per shot so do I shave a little more off the hammer or start clipping on the spring. After all, I did buy a couple extra springs from PyramydAir to play with. Took some time to ponder; that’s when I had a brain storm and decided to short stroke the hammer.

I dug out a hardened washer to attach to the business end of the hammer. I did not want to permanently attach it until I knew it would work with my setup, so I temporarily tack welded the washer onto the hammer for testing purposes and then turned down the outside edges slightly on the red-neck lathe. The washer thickness is 2.24mm. I didn’t want to remove too much more weight at this point, because there is now shorter travel to reach the valve stem and the extra weight from the washer may come in handy in order to open the valve fully.

Hammer weight 39.91grams with hardened steel washer tack welded

Total hammer weight has now increased about 2 grams after adding the washer.

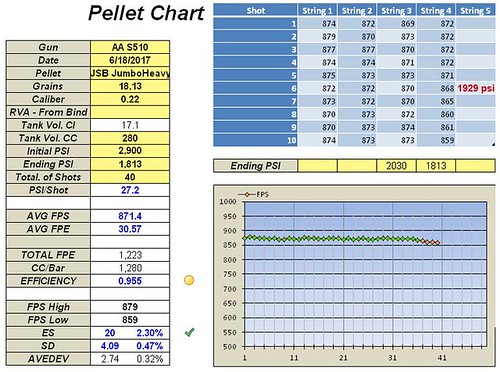

Below is the Chart showing results of a 40 shot string with the Short Stroke Hammer (39.91g).

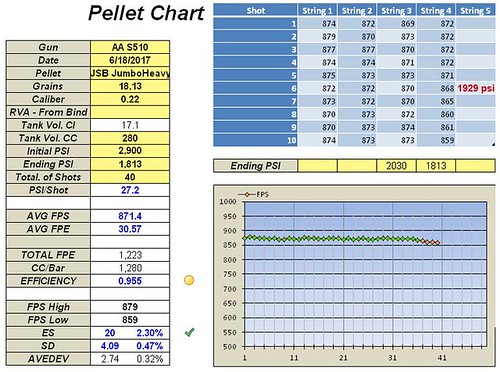

Filled to 200Bar (2900psi) and ended at 125Bar (1813psi). Rifle now averaged 871fps at 30.57fpe with an ES of 20 using about 27.2 psi/shot.

Hey!! It appears I have reached my goal right.......well sort of. Efficiency is not where it should be. Rifle is getting about 36 shots before falling off regulator.

Regulator set at 135Bar, Stock Hammer Spring 61.97mm

Short-stroked hammer weight at 39.91grams

I am now leery of taking any more weight off the hammer so I think the next step is a little tweaking of the hammer spring.

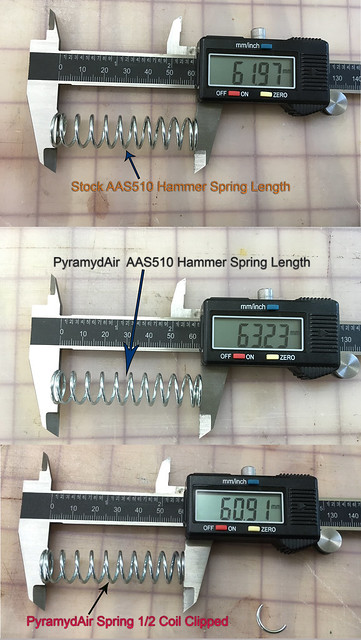

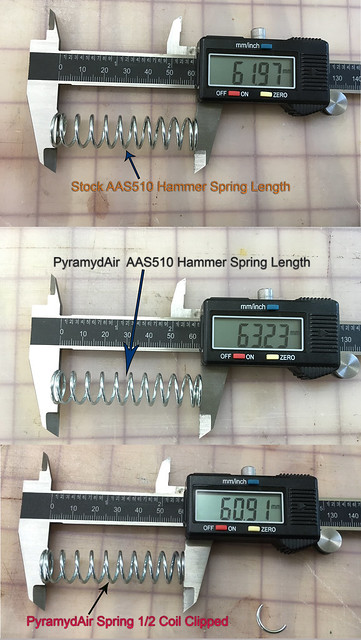

I didn’t want to trim on the stock hammer spring so it was swapped out for one from PyramydAir. Clipped 1/2 coil off the PyramydAir spring then heated end to close gap. Ground it flat on disc sander. It is now 1.06mm shorter than stock spring for a length of 60.91mm. Seemed like a good place to start.

Clipped PyramydAir Spring to 60.91mm

Below is a link to video of how to shorten a hammer spring and close the end.

https://youtu.be/gI4_yt04wUA

At this point I committed fully to the shorter stroke; therefore, I Silver-brazed the washer to the hammer (Stronger than the temporary tack weld). Now hammer weight is slightly heavier at 40.19 grams.

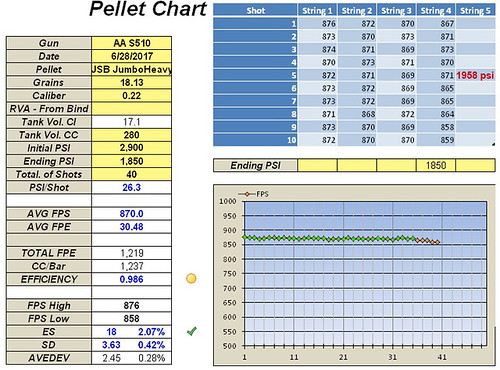

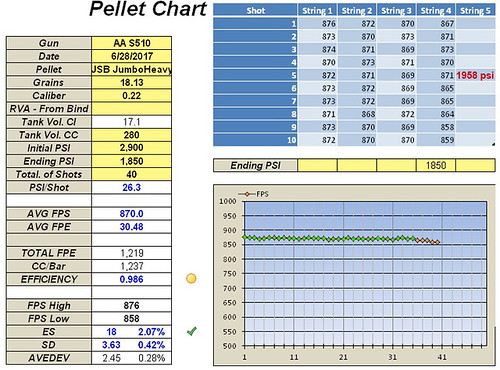

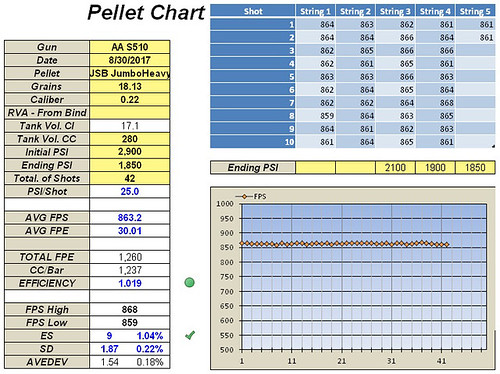

Installed the shorter 60.91mm spring and Short Stroke hammer then fired 40 pellets over the chronograph. Chart below contains results.

Filled to 200Bar (2900psi) and ended at 127.5Bar (1850psi). Rifle now averaged 870fps at 30.48fpe with an ES of 18 using about 26.3 psi/shot. There is a slight improvement in efficiency by about 1 psi/ shot with the shorter spring.

Regulator set at 135Bar, New Hammer Spring 60.91mm

Short-stroked hammer weight at 40.19 grams

I liked the results so I decided to leave that spring alone and just cut the other new PyramydAir spring down for further testing. It ended up being 58.02mm which is about 3mm shorter than previous.

Now it was time to test the new spring length. Fired 56 shots over chronograph and below are the results of 51 of those shots. Filled to 200Bar (2900psi) and ended at 120.6Bar (1720psi). Rifle now averaged 843fps at 28.6fpe with an ES of 23 using about 23.1 psi/shot.

That’s over 50 shots on a 200bar fill with a decent ES and the efficiency looks pretty good also. As you can read in green print on the pellet chart below, the first 40 shots of the string were within 17ES which falls within my set parameters. So can I live with 28- 29fpe to gain an extra 10 shots? Maybe….we shall see. For now, I am not finished experimenting yet. Seems the spring is a smidge too short now and not opening the valve fully as velocity dropped a bit.

Regulator set at 135Bar, New Hammer Spring 58.02mm

Short-stroked hammer weight at 40.19 grams

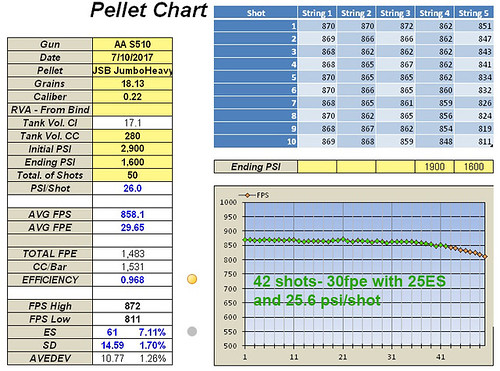

To compensate for the decrease in velocity and the slight rise at the end of the string, I turned the regulator down to about 130bar give or take and put the slightly longer spring(60.91mm) back in .That should let the spring /hammer combo open the valve a bit more and bring velocity back up a bit.

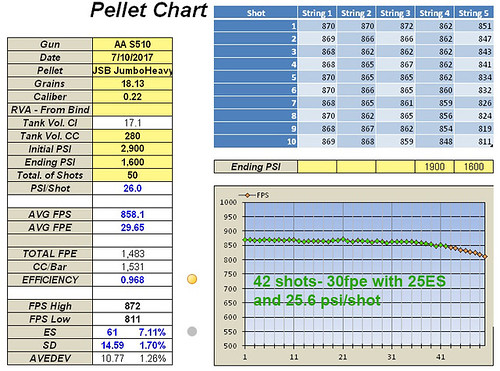

Filled to 200Bar (2900psi) and shot 50 pellets over the chronograph. The ending cylinder pressure was 110Bar (1600psi). Rifle now averaged 858fps at 29.7fpe with an ES of 61. So the velocity is back up a bit but efficiency is back down using about 26 psi/shot.

42 of those shots (shown in green on the pellet chart below) had an average of 864fps at 30fpe and an ES of 25 using 25.6 psi/shot.

Regulator set at 130Bar, New Hammer Spring 60.91mm

Short-stroke hammer weight at 40.19 grams

Finding a happy medium between the last two shot strings would be great.

I was feeling brave, so I trimmed some more weight off the hammer to see what would happen. No turning back now. Also decided to put the shorter 58.02mm spring back in at the same time.

My care free attitude about lightening the hammer even more is due the fact I have an Anti-Bounce Hammer kit from Lane Regulators in my possession, which I will install at a later date for comparison.

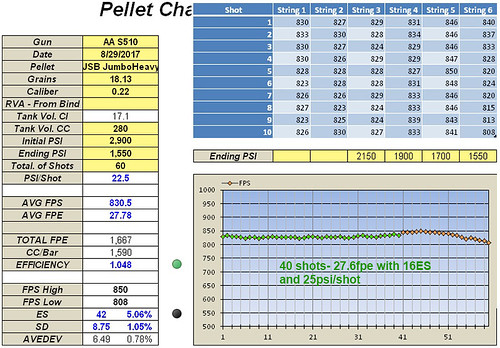

The lightened short-stroke hammer now weighs in at 36.27 grams. About four grams lighter than before.

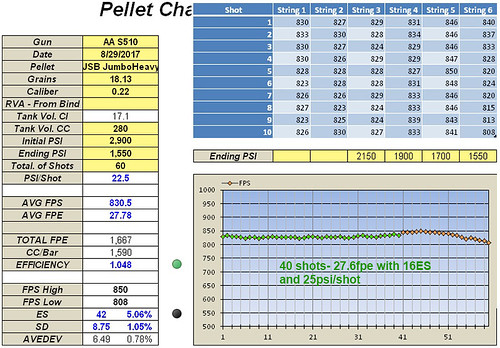

Start fill pressure was 200Bar (2900psi). Shot 60 pellets over the chronograph. End cylinder pressure was 107Bar (1550psi). Rifle now averaged 830.5fps at 27.78fpe with an ES of 42.

Pellet Chart below shows details of the 60 shot string.

Regulator set at 130Bar, New Hammer Spring 58.02mm,

Lightened Short-stroke hammer weight now at 36.27 grams

As you can see, the rifle falls off the regulator at 40 shots and is only averaging 27.8fpe. Well under my 30fpe goal. On the other hand, it was getting 60 usable hunting shots which I think is great.

Notice there is a rise in velocity after shot 40 so it seems the hammer spring should be a bit heavier/longer to compensate. So, on this next test, I swapped out the 58.02mm spring for the slightly longer 61.97mm original stock hammer spring to give it a little kick in the butt.

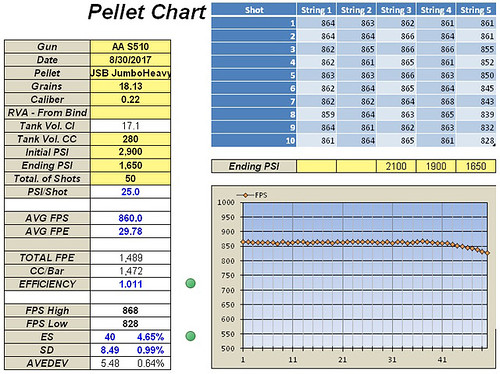

Results for a 50 shot string are below.

Regulator set at 130Bar, 2900PSI fill, Stock Hammer Spring 61.97mm,

Lightened Short-stroke hammer weight now at 36.27 grams

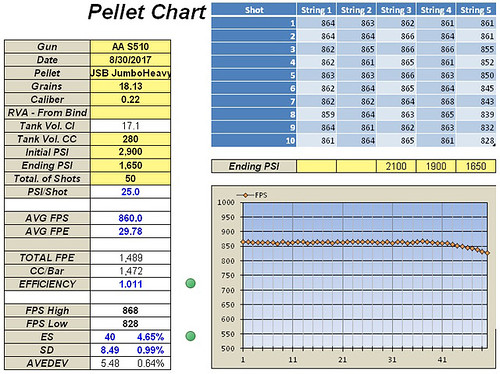

Well that 50 shot string put a big smile on my face. Fill pressure started at 200Bar (2900psi) and ended at 113Bar (1650psi).

After swapping springs, velocity is back up where I want it averaging 860fps at 29.7fpe with an ES of 40.

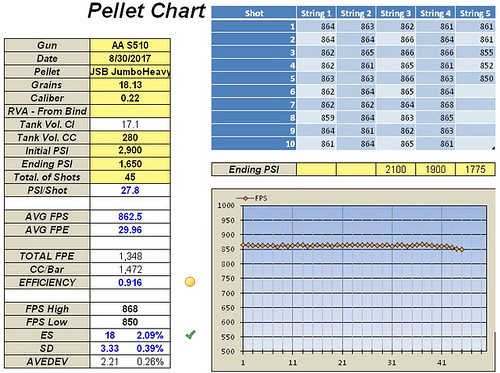

Now if we look back, my original goal was to get at least 40 shots averaging 30fpe with an ES of 20 or less. So let’s break this pellet chart down a bit. Below is the same chart showing results of the first 45 shots only.

Same Chart as above showing first 45 shots

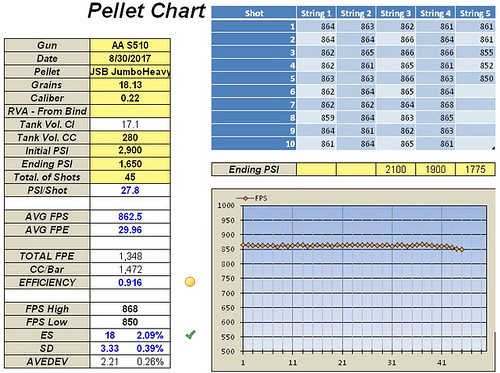

As you can see she averaged 862.5fps at 29.96fpe with an ES of 18 for 45 shots. Cylinder pressure ended at 122Bar (1775psi) best I could tell. This exceeds my expectations.

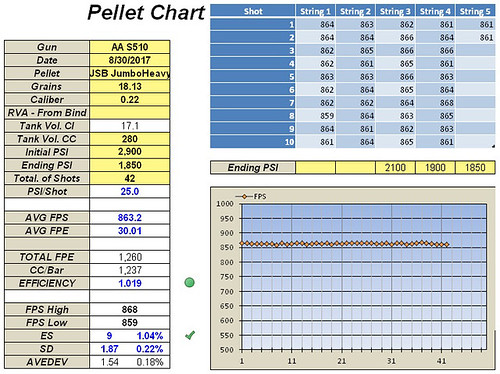

If we break this same shot string down to the first 42 shots the Extreme Spread is in the single digits.

See Pellet Chart below.

Same Chart as above showing first 42 shots

Descent results for 42 shots I think. She averaged 863fps at 30.0fpe with an ES of 9.

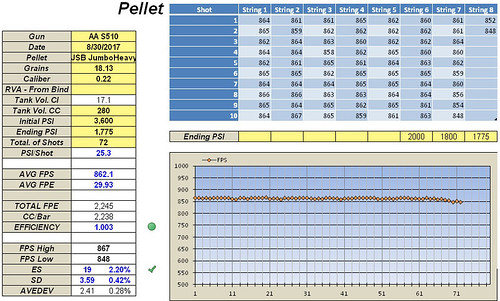

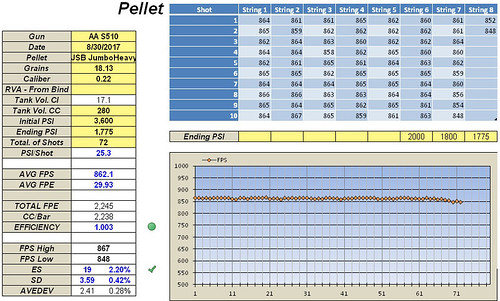

Ok… so now some of you may be curious as to how many shots it will get on a 250Bar (3600psi) fill. Well, I wanted to know also. So below is another pellet chart that shows just that.

Regulator set at 130Bar, 3600PSI fill, Stock Hammer Spring 61.97mm,

Lightened Short-stroke hammer weight now at 36.27 grams

As you can see from the nice flat string the rifle is performing very well with the new Altaros regulator. Final result of the 3600psi fill is 72 shots averaging 862fps at 29.9fpe with an ES of 19. Ending pressure in cylinder was 122Bar (1775psi) which is about 25.3 psi/shot.

So my conclusion to this Air Odyssey is that short stroking my AA S510 was a resounding success. And although they’re not a plug-n-play devices, the Altaros Regulators are simple to install, easy to adjust, there is no drilling of the air cylinder and the gauge will still read cylinder pressure. But most importantly….. the regulator is providing great results. I have found filling it to 2900psi yields 40+ shots, filling to 3100psi yields 50+ shots and a 3200psi fill will get me 60+ shots. Which works out great because I happen to have (6) 10 shot mags.

Well, I am in the middle of a fun little project replacing O-Rings, installing an Altaros Regulator and performing a layman's tune on my AAS510 Extra (Inspired by Matt Dubber). I want to stress that although I have rebuilt several PCP's, most of what I post here is experimental and not based on technical knowledge. I will be posting my progress and results of short-stroking this air-arms S510 air rifle on the slim chance someone is interested.

To begin, finding exact O-ring sizes online for this rifle and certain others for that matter seems to be hit and miss or top secret. So, after extensive research and taking my own measurements, I finally came up with an easy to read O-ring chart containing the different sizes needed to rebuild an AirArms Model S410 & S510 (link to chart below). PyramydAir carries an O-ring kit, but note that it is only for the bottom end. Full service kits are available from the UK, but it's a longer wait and runs the risk of getting stuck or lost at Customs. In the end, ordering from theoringstore.com was the logical choice for me.

Link to O-Ring size chart for AirArms S510 https://flic.kr/p/W9NeTW

Link to Parts List for AirArms S510 https://flic.kr/p/W9NfgQ

O-ring size chart .Pdf https://drive.google.com/file/d/0B5Nu6UixbtYRR011R1VDRnJxUGM/view?usp=sharing

I won't bore you with the rebuild itself or the Altaros Regulator install in this post, but here is a link to a very long comprehensive video of the AAS510 tear-down, regulator install and O-ring replacement if interested. The video also includes shroud removal and O-ring change on the inner barrel tube support which is Important for accuracy.

https://youtu.be/HQAfyI6qSqA

The rifle I am working on is an AAS510 Extra FAC in .22cal.

Before making any changes to the rifle, I filled it to the factory recommended 200Bar (2900psi) and put 40 shots down the barrel using JSB Jumbo Heavy 18.13gr over the chronograph before installing the regulator. That gave me a baseline for the tune and a realistic idea of what to expect from the rifle after the regulator install. Pellet Chart below shows results. Rifle averaged 894fps at 32.19fpe. End pressure was 1885psi. That is about 25.4 psi/shot with an ES of 62

Only 18-20 shots in the 20ES range.

40 shots Pre Regulator, Stock Hammer Spring 61.97mm, Stock Hammer

Based on these results, I have set a goal to achieve at least 40 shots at 30fpe on a 200Bar fill (2900psi) using JSB Jumbo Heavy 18.13gr with an ES of 20 or under.

The Altaros regulator was then installed while retaining the original valve spring, hammer and hammer spring. I did not change the factory settings on regulator. It is as I received it.

The reason I went with the Altaros brand is the fact there is no drilling the cylinder and the gauge will still read cylinder pressure after installation.

Regulator screw position as set from factory

After shooting over the chronograph it appears the regulator was set to 110Bar+-. Pellet Chart below shows the result of 40 shots from a 200Bar (2900psi) fill down to 90bar (1305psi) for an average of 817fps at 26.89fpe. That’s about 39.9 psi/shot with an ES of 77. As expected, it is using a bunch of air and the specs are well under my objective.

Regulator 110Bar, Stock Hammer Spring 61.97mm, Stock Hammer

To reduce air consumption, I had a choice of cranking up the regulator to help balance out the heavy hammer and spring, replacing the valve spring with a heavier one, turning the hammer down to remove some weight or maybe shorten/lighten the hammer spring. Given the fact that I was only getting 817 fps average, I decided to adjust the regulator first and leave everything else as is for now. I turned the screw on the regulator counter-clockwise (as per Altaros online instructions) until it reached the red mark (Maxed out I think). Altaros claims it should be around 150Bar at the red mark.

Regulator set to max

Put the rifle back together and test fired over the chronograph.

She got 28 shots on the regulator. Pellet Chart below shows a 40 shot string from a 200Bar (2900psi) fill down to 110bar (1595psi). It had an average of 862fps at 29.89fpe with an ES of 67. That is 32.6 psi/shot. Bad news is that the regulator is maxed out at 135Bar. Better news is that I reached my FPE and ES goal within those 28 regulated shots. It’s now time to work on that shot count.

Regulator 135Bar, Stock Hammer Spring 61.97mm, Stock Hammer

Next step....I decided to remove some weight off the hammer. Factory hammer weight was 49.59 grams. I turned it down a little and ended up with a weight of 40.42 grams. I do not have a lathe so I improvised using a drill press, die grinder and a couple files. Check out video link if interested in that Red-neck technique.

I then installed the lighter hammer leaving everything else as is. Test fired over chronograph again. Pellet Chart results are shown below. Rifle was getting 33 shots before falling off regulator. 40 shots averaged 867fps at 30.30fpe with an ES of 52. Now it is using 29 psi/shot. I did not lose any velocity but gained 5 shots. Getting closer to my goal. Now time to shave the hammer a bit further to save a little more air.

Regulator set at 135Bar, Stock Hammer Spring 61.97mm and Hammer lightened to 40.42grams

Back to the drill press and took a few more grams off the hammer. It is now down to 37.81grams.

Installed lighter hammer and fired 40 pellets over chronograph again.

Chart results posted below, but not much change. I gained maybe one shot for a total of 34 shots before falling off reg. Interesting thing though, I noticed when it falls off the regulator the velocity does not drop as fast. Around 20fps higher at shot 40, making the shots 35-40 curve a little flatter. Rifle averaged 871fps at 30.60fpe with an ES of 33. Air consumption is now 27.2psi/shot.

Hmmmmmmm.......I expected better results.

Regulator set at 135Bar, Stock Hammer Spring 61.97mm and Hammer lightened to 37.81grams

At this point I debated which direction to go. I needed to use less air per shot so do I shave a little more off the hammer or start clipping on the spring. After all, I did buy a couple extra springs from PyramydAir to play with. Took some time to ponder; that’s when I had a brain storm and decided to short stroke the hammer.

I dug out a hardened washer to attach to the business end of the hammer. I did not want to permanently attach it until I knew it would work with my setup, so I temporarily tack welded the washer onto the hammer for testing purposes and then turned down the outside edges slightly on the red-neck lathe. The washer thickness is 2.24mm. I didn’t want to remove too much more weight at this point, because there is now shorter travel to reach the valve stem and the extra weight from the washer may come in handy in order to open the valve fully.

Hammer weight 39.91grams with hardened steel washer tack welded

Total hammer weight has now increased about 2 grams after adding the washer.

Below is the Chart showing results of a 40 shot string with the Short Stroke Hammer (39.91g).

Filled to 200Bar (2900psi) and ended at 125Bar (1813psi). Rifle now averaged 871fps at 30.57fpe with an ES of 20 using about 27.2 psi/shot.

Hey!! It appears I have reached my goal right.......well sort of. Efficiency is not where it should be. Rifle is getting about 36 shots before falling off regulator.

Regulator set at 135Bar, Stock Hammer Spring 61.97mm

Short-stroked hammer weight at 39.91grams

I am now leery of taking any more weight off the hammer so I think the next step is a little tweaking of the hammer spring.

I didn’t want to trim on the stock hammer spring so it was swapped out for one from PyramydAir. Clipped 1/2 coil off the PyramydAir spring then heated end to close gap. Ground it flat on disc sander. It is now 1.06mm shorter than stock spring for a length of 60.91mm. Seemed like a good place to start.

Clipped PyramydAir Spring to 60.91mm

Below is a link to video of how to shorten a hammer spring and close the end.

https://youtu.be/gI4_yt04wUA

At this point I committed fully to the shorter stroke; therefore, I Silver-brazed the washer to the hammer (Stronger than the temporary tack weld). Now hammer weight is slightly heavier at 40.19 grams.

Installed the shorter 60.91mm spring and Short Stroke hammer then fired 40 pellets over the chronograph. Chart below contains results.

Filled to 200Bar (2900psi) and ended at 127.5Bar (1850psi). Rifle now averaged 870fps at 30.48fpe with an ES of 18 using about 26.3 psi/shot. There is a slight improvement in efficiency by about 1 psi/ shot with the shorter spring.

Regulator set at 135Bar, New Hammer Spring 60.91mm

Short-stroked hammer weight at 40.19 grams

I liked the results so I decided to leave that spring alone and just cut the other new PyramydAir spring down for further testing. It ended up being 58.02mm which is about 3mm shorter than previous.

Now it was time to test the new spring length. Fired 56 shots over chronograph and below are the results of 51 of those shots. Filled to 200Bar (2900psi) and ended at 120.6Bar (1720psi). Rifle now averaged 843fps at 28.6fpe with an ES of 23 using about 23.1 psi/shot.

That’s over 50 shots on a 200bar fill with a decent ES and the efficiency looks pretty good also. As you can read in green print on the pellet chart below, the first 40 shots of the string were within 17ES which falls within my set parameters. So can I live with 28- 29fpe to gain an extra 10 shots? Maybe….we shall see. For now, I am not finished experimenting yet. Seems the spring is a smidge too short now and not opening the valve fully as velocity dropped a bit.

Regulator set at 135Bar, New Hammer Spring 58.02mm

Short-stroked hammer weight at 40.19 grams

To compensate for the decrease in velocity and the slight rise at the end of the string, I turned the regulator down to about 130bar give or take and put the slightly longer spring(60.91mm) back in .That should let the spring /hammer combo open the valve a bit more and bring velocity back up a bit.

Filled to 200Bar (2900psi) and shot 50 pellets over the chronograph. The ending cylinder pressure was 110Bar (1600psi). Rifle now averaged 858fps at 29.7fpe with an ES of 61. So the velocity is back up a bit but efficiency is back down using about 26 psi/shot.

42 of those shots (shown in green on the pellet chart below) had an average of 864fps at 30fpe and an ES of 25 using 25.6 psi/shot.

Regulator set at 130Bar, New Hammer Spring 60.91mm

Short-stroke hammer weight at 40.19 grams

Finding a happy medium between the last two shot strings would be great.

I was feeling brave, so I trimmed some more weight off the hammer to see what would happen. No turning back now. Also decided to put the shorter 58.02mm spring back in at the same time.

My care free attitude about lightening the hammer even more is due the fact I have an Anti-Bounce Hammer kit from Lane Regulators in my possession, which I will install at a later date for comparison.

The lightened short-stroke hammer now weighs in at 36.27 grams. About four grams lighter than before.

Start fill pressure was 200Bar (2900psi). Shot 60 pellets over the chronograph. End cylinder pressure was 107Bar (1550psi). Rifle now averaged 830.5fps at 27.78fpe with an ES of 42.

Pellet Chart below shows details of the 60 shot string.

Regulator set at 130Bar, New Hammer Spring 58.02mm,

Lightened Short-stroke hammer weight now at 36.27 grams

As you can see, the rifle falls off the regulator at 40 shots and is only averaging 27.8fpe. Well under my 30fpe goal. On the other hand, it was getting 60 usable hunting shots which I think is great.

Notice there is a rise in velocity after shot 40 so it seems the hammer spring should be a bit heavier/longer to compensate. So, on this next test, I swapped out the 58.02mm spring for the slightly longer 61.97mm original stock hammer spring to give it a little kick in the butt.

Results for a 50 shot string are below.

Regulator set at 130Bar, 2900PSI fill, Stock Hammer Spring 61.97mm,

Lightened Short-stroke hammer weight now at 36.27 grams

Well that 50 shot string put a big smile on my face. Fill pressure started at 200Bar (2900psi) and ended at 113Bar (1650psi).

After swapping springs, velocity is back up where I want it averaging 860fps at 29.7fpe with an ES of 40.

Now if we look back, my original goal was to get at least 40 shots averaging 30fpe with an ES of 20 or less. So let’s break this pellet chart down a bit. Below is the same chart showing results of the first 45 shots only.

Same Chart as above showing first 45 shots

As you can see she averaged 862.5fps at 29.96fpe with an ES of 18 for 45 shots. Cylinder pressure ended at 122Bar (1775psi) best I could tell. This exceeds my expectations.

If we break this same shot string down to the first 42 shots the Extreme Spread is in the single digits.

See Pellet Chart below.

Same Chart as above showing first 42 shots

Descent results for 42 shots I think. She averaged 863fps at 30.0fpe with an ES of 9.

Ok… so now some of you may be curious as to how many shots it will get on a 250Bar (3600psi) fill. Well, I wanted to know also. So below is another pellet chart that shows just that.

Regulator set at 130Bar, 3600PSI fill, Stock Hammer Spring 61.97mm,

Lightened Short-stroke hammer weight now at 36.27 grams

As you can see from the nice flat string the rifle is performing very well with the new Altaros regulator. Final result of the 3600psi fill is 72 shots averaging 862fps at 29.9fpe with an ES of 19. Ending pressure in cylinder was 122Bar (1775psi) which is about 25.3 psi/shot.

So my conclusion to this Air Odyssey is that short stroking my AA S510 was a resounding success. And although they’re not a plug-n-play devices, the Altaros Regulators are simple to install, easy to adjust, there is no drilling of the air cylinder and the gauge will still read cylinder pressure. But most importantly….. the regulator is providing great results. I have found filling it to 2900psi yields 40+ shots, filling to 3100psi yields 50+ shots and a 3200psi fill will get me 60+ shots. Which works out great because I happen to have (6) 10 shot mags.