After a year and a half the booster stopped working, would not build pressure on the second stage, so took a look inside

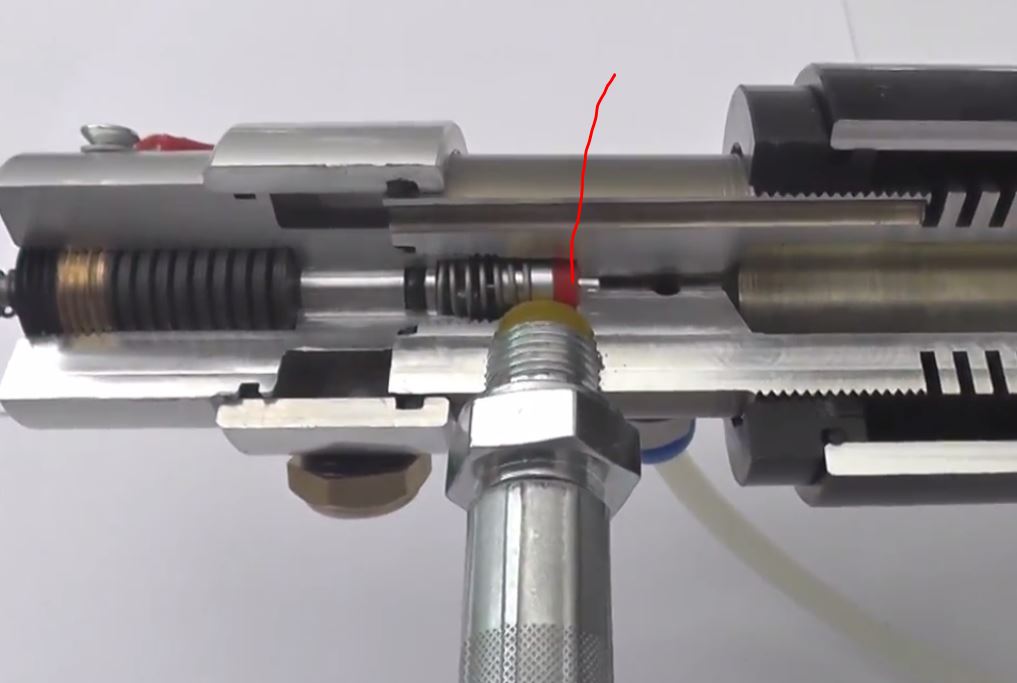

The high pressure valve guide and spring was covered in a lot of stuff I do not know where came from, not from the seal, maybe some kind of grease used, but not surely not something I want to get in my gun, cleaned it all out, was in the exit tube too, yikes!

This is what the poppet seal looked like

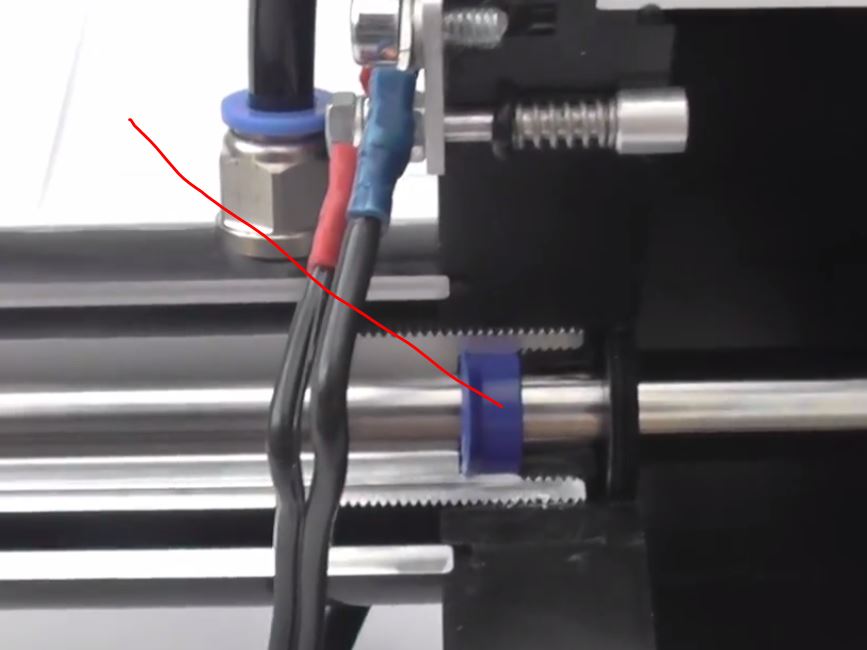

was no spare one in the repair set so made a new one of delrin, I do not know if it will hold up against the heat so will run slow until I get an original one from Altaros, but for now it works ok

also changed the 2. stage standing seal, used a small amount of grease from the repair set to lubricate the piston stem and seal, this stuff is white and do not look like the stuff I found inside at all

The high pressure valve guide and spring was covered in a lot of stuff I do not know where came from, not from the seal, maybe some kind of grease used, but not surely not something I want to get in my gun, cleaned it all out, was in the exit tube too, yikes!

This is what the poppet seal looked like

was no spare one in the repair set so made a new one of delrin, I do not know if it will hold up against the heat so will run slow until I get an original one from Altaros, but for now it works ok

also changed the 2. stage standing seal, used a small amount of grease from the repair set to lubricate the piston stem and seal, this stuff is white and do not look like the stuff I found inside at all