You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Alpha vs Diablo In Line Moisture Filters

- Thread starter FredSG

- Start date

Did you read this post..Im sure u did.

http://airgunnation.dev/topic/warning-exploding-air-hose-on-airguns-of-arizons-diablo-air-dryer-tolerance/

http://airgunnation.dev/topic/warning-exploding-air-hose-on-airguns-of-arizons-diablo-air-dryer-tolerance/

Upvote 0

Linsfreak,

It will be interesting to see if you get a brass fitting like I did and if it will fit and clamp onto your male fosters without being modified. Keep this thread informed please.

Also, I'd really recommend starting with an empty tank and fill it from 0 to your final fill psi. If you got a bad hose like I did and you expose it to a tank at 180 or 200 bar, you are gonna have a heck of a bang on your hands.

It will be interesting to see if you get a brass fitting like I did and if it will fit and clamp onto your male fosters without being modified. Keep this thread informed please.

Also, I'd really recommend starting with an empty tank and fill it from 0 to your final fill psi. If you got a bad hose like I did and you expose it to a tank at 180 or 200 bar, you are gonna have a heck of a bang on your hands.

Upvote 0

All right hopefully it is all good when I get it. When I ordered it I asked what compressor it was for? He stated ShoeBox. .......We shall see.?

Upvote 0

If you get the brass female fitting like mine (which is .750) you aren't going to be able to connect it to a shoebox's male as the opening to the male in Shoebox is only .711

Hopefully you have a hose with two normal females on it (like air compressor to airtank) so you can go with that between the shoebox and Diable then female dryer to air tank male or gun male.

Hopefully you have a hose with two normal females on it (like air compressor to airtank) so you can go with that between the shoebox and Diable then female dryer to air tank male or gun male.

Upvote 0

From another thread here:

Here is a quick review of the Joe Brancato Alpha (JBA for the rest of this review) vs the Diablo. I'm not Michael or Hold over Ted so keep your expectations down....

Here is a picture of the two side by side. If we were buying based on simplicity and professional finish, well I think the Diablo would take it hands down. If looks didn't matter and we were looking for something with functionality, well, one would go with the JBA filter. The Diablo looks like the marketing department won out. The JBA looks like the engineers did all the work and didn't tell the marketing folks before it got shipped. I'm an engineer by background so that's a compliment.

And for all of us too lazy to RTFM, Joe put the manual right onto the unit. Pretty? No. Functional, Yea. Plus he can say "I told you so" when someone wonders why air doesn't immediately go from compressor to tank when you call to say 'My tank gauge doesn't go up right away like it used to".

Ok, so now that the bathing suit contest is over, let's move onto the talent show.

First, in the picture above please point out the pressure bleed off device on the JBA and Diablo. Ok, that's a trick question. There isn't one on the Diablo. What does that mean? Well, when you are done charging your tank and want to disconnect, The high pressure air + moisture + oils from compressor + particles from desiccant + desiccants release (let call it high pressure stuff) has to go somewhere. With the JBA, turn the knob at the bottom (dirty side of filter/dryer) and it bleeds off into the atmosphere (or paper towels or whatever). If you have the female on the Diablo connected to your compressor, your are going to have to open the compressors bleed valve which is going to send all the high pressure stuff back into your compressor. I hope you don't have that Diablo female on your tank as that high pressure stuff is going though your tanks valve to atmosphere. And remember as high pressure stuff expands it releases moisture, gets cooler, and deposits stuff on/in your fittings. I thought the point of a filter/dryer was not to get stuff in our tank so I guess it's headed back into the compressor, eh?

Second, take a look at the picture below and tell me what the pressure in the two disconnected units are. Ok, that's a trick question unless you have both of these to examine. The JBA is easy: take a look at it's gauge. Hey! Wait a second. The JBA is disconnected and it's showing 1900 psi!!! What's going on? Guess we have another of those "simple and looks good" vs "engineer design" things going on. Where you have that clean looking male foster on the Diablo you have a bunch of fittings and adapters on the JBA. Did the JBA just run out of the right fitting and have to use all those to get to a male foster? Uh, no. There is a check valve on the output stack of the JBA. Even though the JBA male foster is not connected, it's holding pressure. Possible benefit, less time to pump that cylinder from 0-1900 psi next time around. Possible benefit, better air control - it's not open to atmosphere after use.

So to build on that..what if one connects a tank at 3000 psi to the JBA and Diablo and opens the valve? On the Diablo, it's going from 0psi to 3000 psi as soon as you open the tank gauge (if its connected to a compressor or something else with a closed air circuit). If the Diablo isn't connected, you are going to blow your tank air though the Diablo into the room. What about if the JBA's other side isn't connected? That valve stack on the JBA is going to stop air from flowing from the tank into the JBA unless the JBA is already at a higher pressure than the tank. So, the the JBA is at 0 and you open a tank at 3000, that valve isn't going to open until your compressor fills the JBA to match at least 1800 then slowly build to 3000 psi. If you've primed the JBA from the compressor to 1700 psi and then open that 3000 psi tank, the compressor will slowly start to take the JBA from 1500 to 3000 gradually opening the valve more as the JBA pressure gets closer to tank pressure.

I'm not going to disassemble the Diablo because I am sending back due to its failure. See the video from someone else earlier in this thread for that.

I will take apart the JBA because I plan to keep it. Step 1, unscrew the base and remove. The first thing you will notice is a spring. That spring is sits betwen the cap and the cartridge to make sure the cartridge stay in place so the desiccant doesn't directly touch the walls of the filter/dryer.

Next, let's take a look inside the JBA filter/dryer. See that dark grey material between the end of the threads and that light grey center piece? That sits between the filter cartridge and the walls of the filter/dryer for the length of the cartridge (you'll see that next). We can also see a felt like filter being held in place my a metallic grate. On the Diablo, all the desiccant material is in a large area between the walls of the filter/dryer. Here it is being forced though a smaller cross section. We'll get into more into that in the next paragraph.

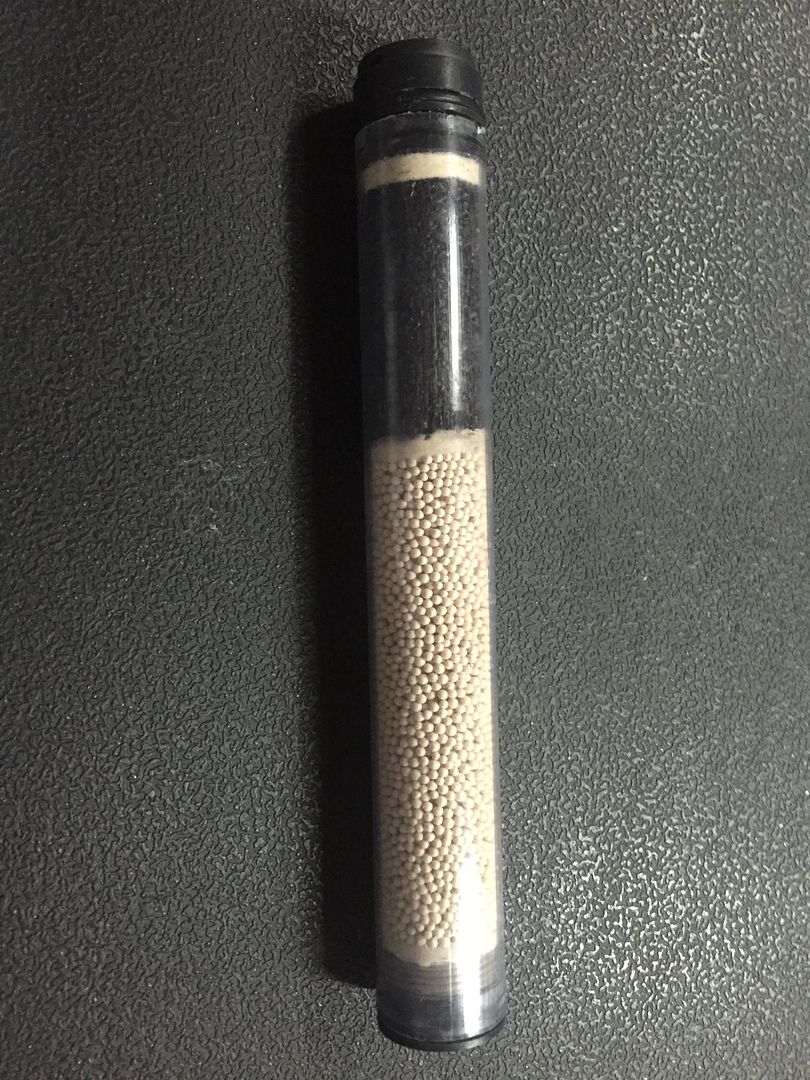

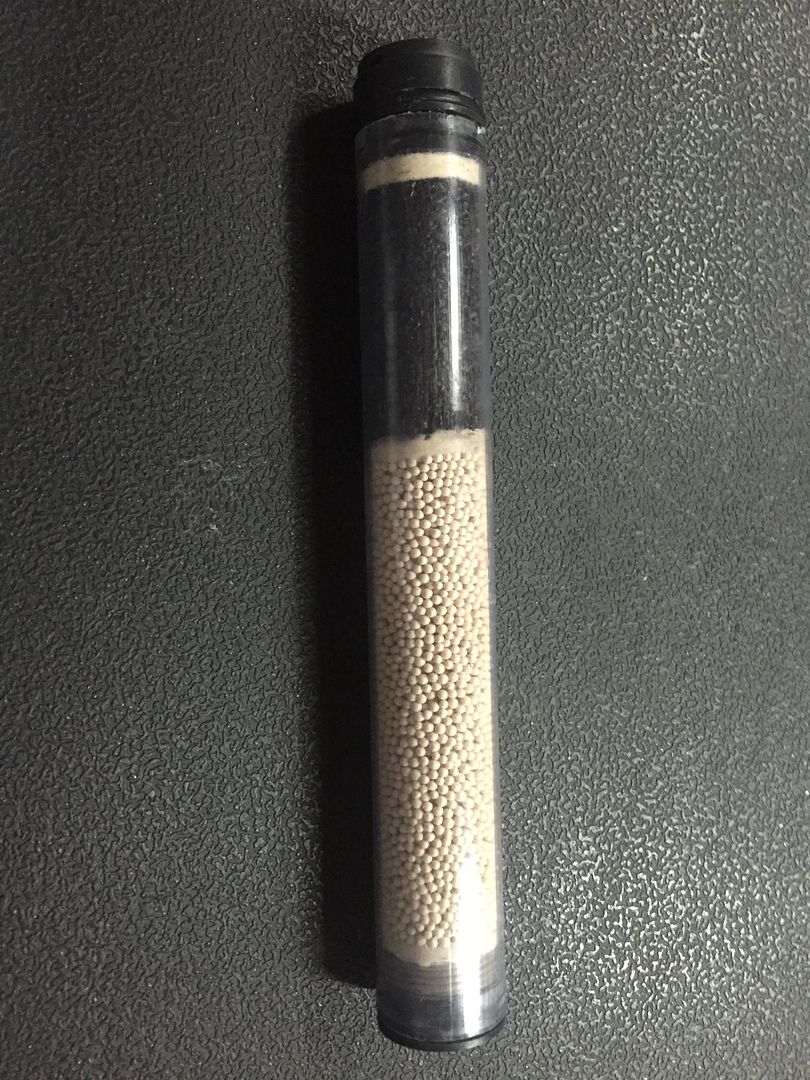

Now, let's remove the filter cartridge from the JBA and look at it in relation to the larger container. This cartridge is completely self contained - another layer of material between the walls of the JBA and the material doing the work. And I think it's a well designed cartridge. First is a rough filter to clean particles and maybe absorb oils. Then comes the moisture removing material. Then comes another separator to keep particles from the desiccant from reaching the next stage. Then comes what looks like an active carbon material, then another separator to ensure that carbon doesn't go somewhere it shouldn't. That's very different than the Diablos design of a loose piece of felt like material that isn't even the same diameter as the inside of the filter dryer 'loosely' sitting between the endcaps and the desiccate material.

And if one compares the size of the desiccant balls we have like roughly twice as many small ones in the JBA to medium ones in the Diablo. Think about it this way: If you could put two soccer balls into a 5 gallon bucket before it's full - think about how much empty space there is around those. Now, fill the same bucket with golf balls - how much empty air space? Now fill it will .177 BBs...see how we keep getting more surface area in contact with air and less 'empty air space' doing nothing. That's happening in these filer/dryers. And there is a spring in the base of this cartridge to keep it all packed tight: Here is a closeup. Compare this to the video of the Diablo

Here is that check valve that I mentioned earlier (center). It works by managing pressure on both sides of the valve.

So next I put the cartridge back in and measured the depth of the end cap with a digital caliper.

And compared that to where the seat of the cap will be in the tube. It's kind hard to tell, but it looks like the end of the cap will snug up into the insulating material in the center of the filter. Am I 100% sure that means any 'acid leakage' from the desiccant will not get into the threads? No, but it looks like some really good design and fitting work was done to try to ensure it doesn't. I'm not saying this works or doesn't - just saying it looks like it was designed to work that way. When one opens the check valve and that vapor full of stuff blows though the cap, yep, it will be in contact with the small hole drilled though the center of the cap. But that would just slowly go after the center of the cap and the bleed valve. That's much better than having thread failure and that big cap and filter turning into a 5000psi propelled projectile!!

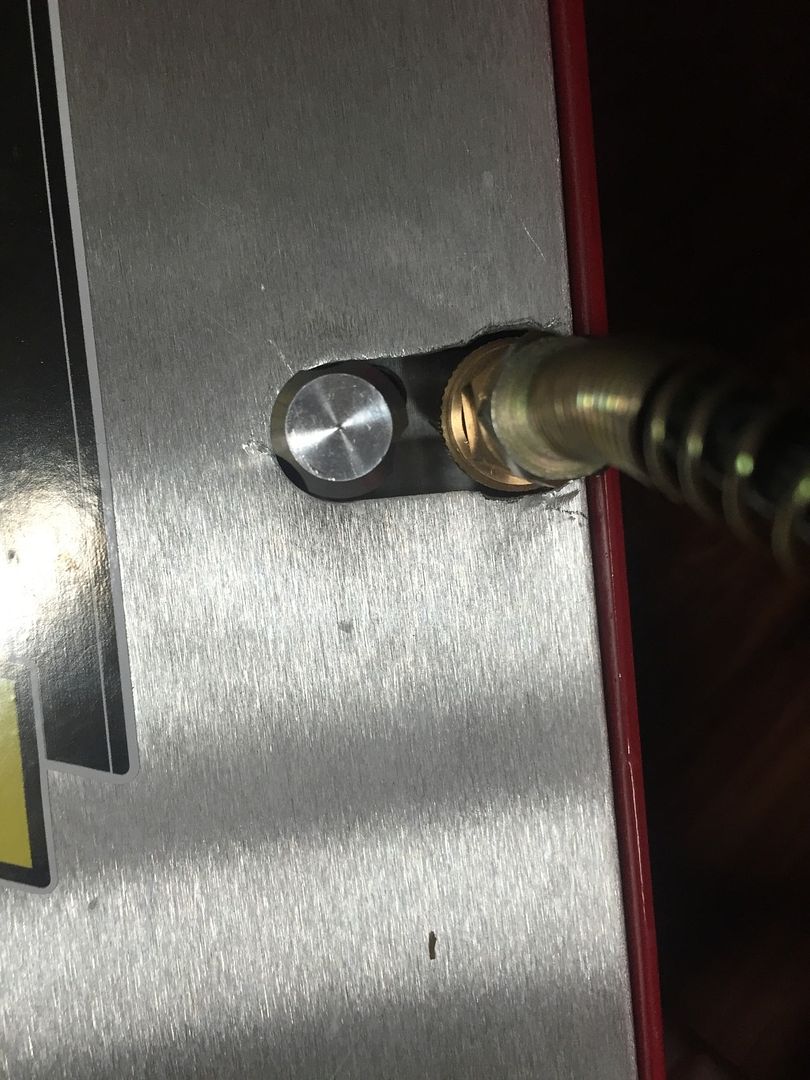

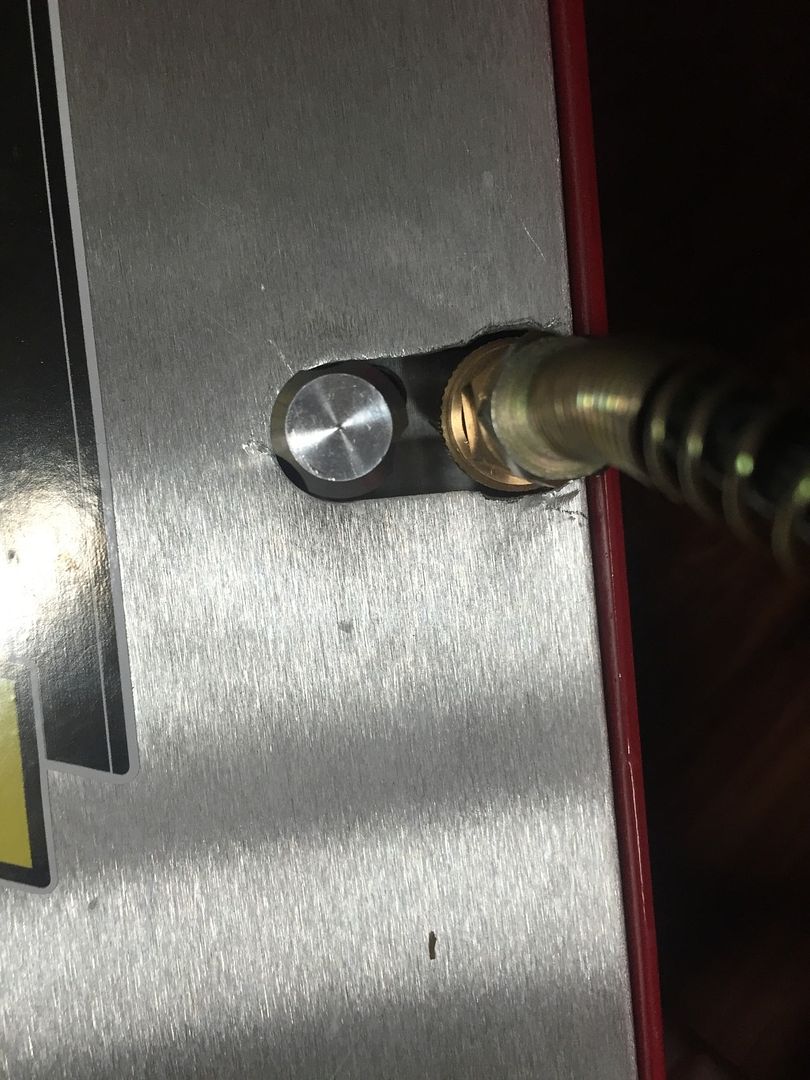

Here is a picture of what you have to do to a ShoeBox to connect the large brass Diablo fitting provided.

Look at how much better the JBA foster connects. Sigh. Hind sight is 20 / 20.

Here is the Diablo with only stage 1 compressor pressure - air always flowing.

http://vid1376.photobucket.com/albums/ah25/B_Scott_Harroff/IMG_2126_zpsml5oi7ii.mp4

here is the JBA - same test - except the JBA is being driven at 1700 psi from the ShoeBox - the check valvle is just starting to open a bit.

http://vid1376.photobucket.com/albums/ah25/B_Scott_Harroff/IMG_2134_zpsun1fxhrl.mp4

So why do we care about the above. Ok, pick up a pack of normal packing gel. Blow over it with your breath. How much moisture do you think it removed. Now put that in a tube and again with your breath blow though it. How much did it remove? More? Yep.

Now - don't do this at home cause I'm a professionally trained nut - blow though the Diable. How much moisture was removed. More than the straw? Yep. Did it get all of it? Nope.

Now - don't do this at home cause I'm a professionally trained nut - blow though the JBA. What do you mean you can't???? Try again. Same result? What's up? The JBA's check valve needs atleast 1700 psi (on mine) to open.

So as the air is flowing aroung the beads in the Diablo, it's being forced to 1700 psi in the JBA before it can leave. The more pressure, the more the air is forced to interact with the desicant meaning the more moisture is removed. And by the same token the more is removed by the active charcoal in the JBA. End result should be inferred:

At 0-100 psi, the cleaning of the air is less than 100-250 which is less than 250-500 which is less than 500-1000 which is less than 1000-1700. The air going into your tank from the Diablo on the first half of your filling isn't going to be as clean and dry as the air that starts leaking into your tank from the JBA starting at 1700 psi. That's a big difference on cleaning the first half of the air going into your tanks, folks!

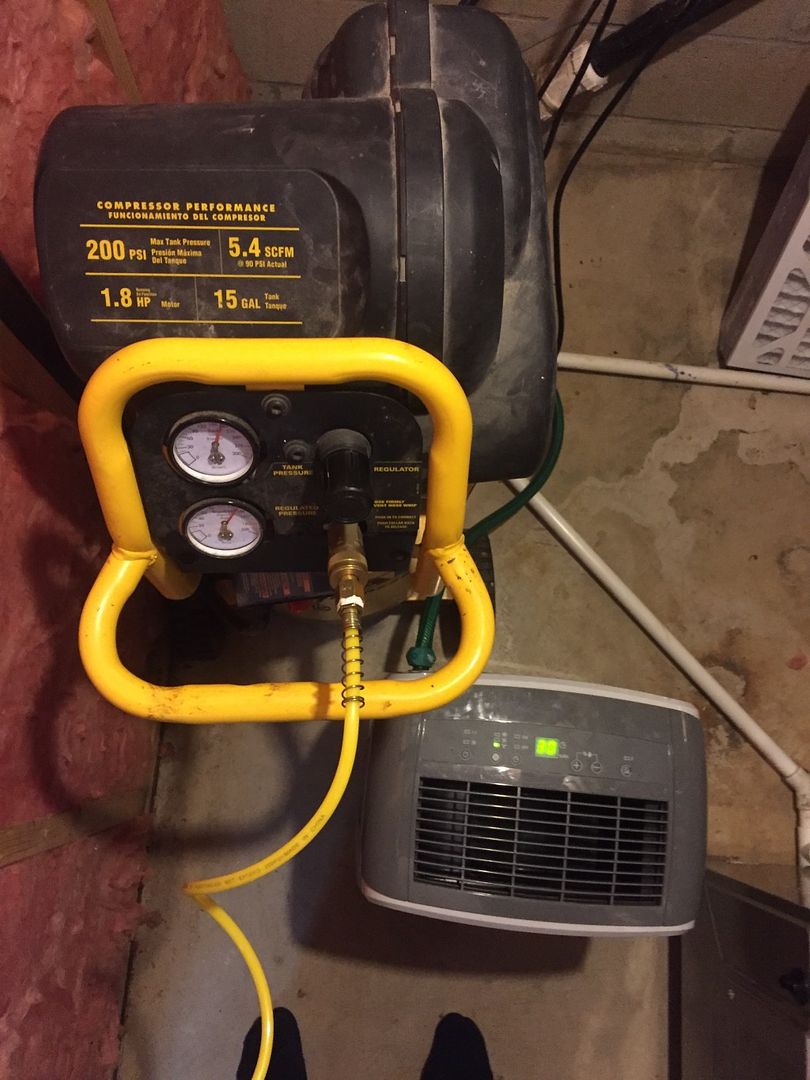

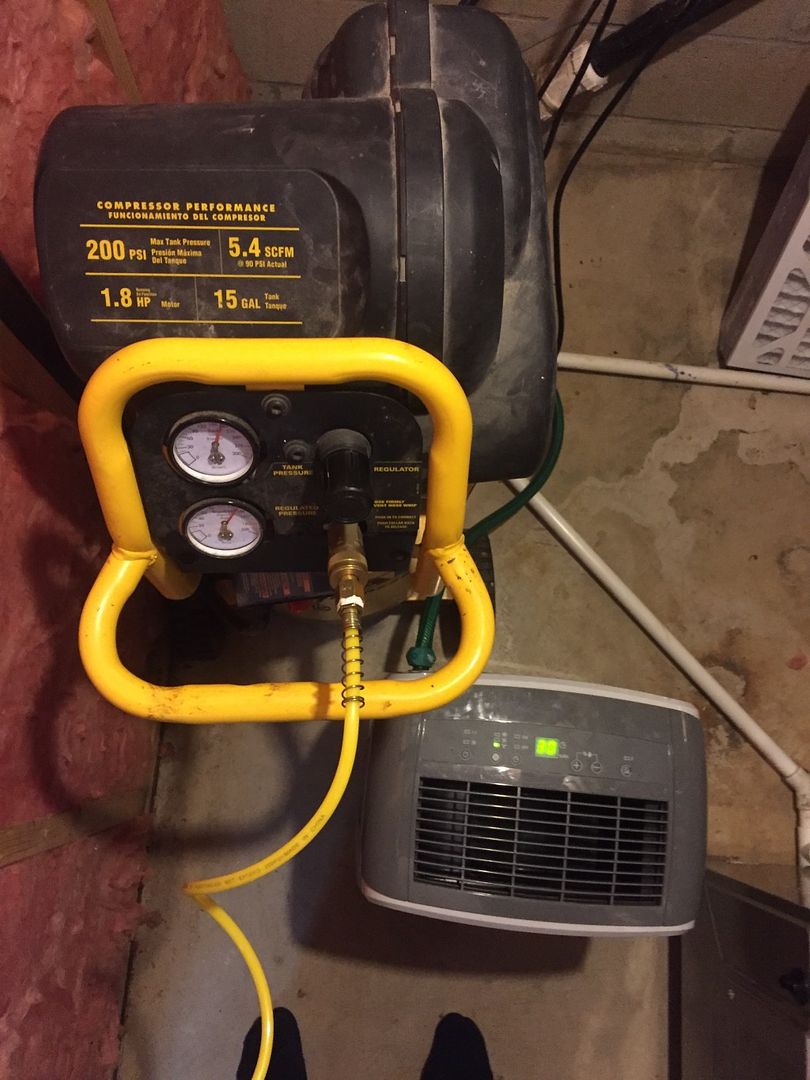

Here is my stage 1 - a 200 psi 15 gallon compressor in a room at 60 degrees and 30 percent humidity via a dehumidifier.

I started off with an empty Tigershark and filled it to 4500 psi. Here is the water and stuff removed by stage 1 - a couple of teaspoons

Here is what I bled off from the JBA at the end - a couple of drops of water and residue from high compression.

I have cool dry air (30% humidity) going into a large tank at 200 psi. I still wound up with drops of water and high pressure 'stuff' on the other end of my shoebox. For you folks with no filter/dryers, that's going into your tanks/guns.

So to wrap this up, I'm not saying the Diablo is bad (other than mine exploded on its first fill at 500 psi). I am saying I think the JBA is better than the Diablo though.

Is the JBA worth the difference? Depends on who you are and what you want. Some folks are really happy with getting a Mrod and customizing. Others are paying a big difference for a Daystate or FX. Some folks aren't even using a dryer on their compressors and pumps.

I'm keeping my JBA!!!

Here is a quick review of the Joe Brancato Alpha (JBA for the rest of this review) vs the Diablo. I'm not Michael or Hold over Ted so keep your expectations down....

Here is a picture of the two side by side. If we were buying based on simplicity and professional finish, well I think the Diablo would take it hands down. If looks didn't matter and we were looking for something with functionality, well, one would go with the JBA filter. The Diablo looks like the marketing department won out. The JBA looks like the engineers did all the work and didn't tell the marketing folks before it got shipped. I'm an engineer by background so that's a compliment.

And for all of us too lazy to RTFM, Joe put the manual right onto the unit. Pretty? No. Functional, Yea. Plus he can say "I told you so" when someone wonders why air doesn't immediately go from compressor to tank when you call to say 'My tank gauge doesn't go up right away like it used to".

Ok, so now that the bathing suit contest is over, let's move onto the talent show.

First, in the picture above please point out the pressure bleed off device on the JBA and Diablo. Ok, that's a trick question. There isn't one on the Diablo. What does that mean? Well, when you are done charging your tank and want to disconnect, The high pressure air + moisture + oils from compressor + particles from desiccant + desiccants release (let call it high pressure stuff) has to go somewhere. With the JBA, turn the knob at the bottom (dirty side of filter/dryer) and it bleeds off into the atmosphere (or paper towels or whatever). If you have the female on the Diablo connected to your compressor, your are going to have to open the compressors bleed valve which is going to send all the high pressure stuff back into your compressor. I hope you don't have that Diablo female on your tank as that high pressure stuff is going though your tanks valve to atmosphere. And remember as high pressure stuff expands it releases moisture, gets cooler, and deposits stuff on/in your fittings. I thought the point of a filter/dryer was not to get stuff in our tank so I guess it's headed back into the compressor, eh?

Second, take a look at the picture below and tell me what the pressure in the two disconnected units are. Ok, that's a trick question unless you have both of these to examine. The JBA is easy: take a look at it's gauge. Hey! Wait a second. The JBA is disconnected and it's showing 1900 psi!!! What's going on? Guess we have another of those "simple and looks good" vs "engineer design" things going on. Where you have that clean looking male foster on the Diablo you have a bunch of fittings and adapters on the JBA. Did the JBA just run out of the right fitting and have to use all those to get to a male foster? Uh, no. There is a check valve on the output stack of the JBA. Even though the JBA male foster is not connected, it's holding pressure. Possible benefit, less time to pump that cylinder from 0-1900 psi next time around. Possible benefit, better air control - it's not open to atmosphere after use.

So to build on that..what if one connects a tank at 3000 psi to the JBA and Diablo and opens the valve? On the Diablo, it's going from 0psi to 3000 psi as soon as you open the tank gauge (if its connected to a compressor or something else with a closed air circuit). If the Diablo isn't connected, you are going to blow your tank air though the Diablo into the room. What about if the JBA's other side isn't connected? That valve stack on the JBA is going to stop air from flowing from the tank into the JBA unless the JBA is already at a higher pressure than the tank. So, the the JBA is at 0 and you open a tank at 3000, that valve isn't going to open until your compressor fills the JBA to match at least 1800 then slowly build to 3000 psi. If you've primed the JBA from the compressor to 1700 psi and then open that 3000 psi tank, the compressor will slowly start to take the JBA from 1500 to 3000 gradually opening the valve more as the JBA pressure gets closer to tank pressure.

I'm not going to disassemble the Diablo because I am sending back due to its failure. See the video from someone else earlier in this thread for that.

I will take apart the JBA because I plan to keep it. Step 1, unscrew the base and remove. The first thing you will notice is a spring. That spring is sits betwen the cap and the cartridge to make sure the cartridge stay in place so the desiccant doesn't directly touch the walls of the filter/dryer.

Next, let's take a look inside the JBA filter/dryer. See that dark grey material between the end of the threads and that light grey center piece? That sits between the filter cartridge and the walls of the filter/dryer for the length of the cartridge (you'll see that next). We can also see a felt like filter being held in place my a metallic grate. On the Diablo, all the desiccant material is in a large area between the walls of the filter/dryer. Here it is being forced though a smaller cross section. We'll get into more into that in the next paragraph.

Now, let's remove the filter cartridge from the JBA and look at it in relation to the larger container. This cartridge is completely self contained - another layer of material between the walls of the JBA and the material doing the work. And I think it's a well designed cartridge. First is a rough filter to clean particles and maybe absorb oils. Then comes the moisture removing material. Then comes another separator to keep particles from the desiccant from reaching the next stage. Then comes what looks like an active carbon material, then another separator to ensure that carbon doesn't go somewhere it shouldn't. That's very different than the Diablos design of a loose piece of felt like material that isn't even the same diameter as the inside of the filter dryer 'loosely' sitting between the endcaps and the desiccate material.

And if one compares the size of the desiccant balls we have like roughly twice as many small ones in the JBA to medium ones in the Diablo. Think about it this way: If you could put two soccer balls into a 5 gallon bucket before it's full - think about how much empty space there is around those. Now, fill the same bucket with golf balls - how much empty air space? Now fill it will .177 BBs...see how we keep getting more surface area in contact with air and less 'empty air space' doing nothing. That's happening in these filer/dryers. And there is a spring in the base of this cartridge to keep it all packed tight: Here is a closeup. Compare this to the video of the Diablo

Here is that check valve that I mentioned earlier (center). It works by managing pressure on both sides of the valve.

So next I put the cartridge back in and measured the depth of the end cap with a digital caliper.

And compared that to where the seat of the cap will be in the tube. It's kind hard to tell, but it looks like the end of the cap will snug up into the insulating material in the center of the filter. Am I 100% sure that means any 'acid leakage' from the desiccant will not get into the threads? No, but it looks like some really good design and fitting work was done to try to ensure it doesn't. I'm not saying this works or doesn't - just saying it looks like it was designed to work that way. When one opens the check valve and that vapor full of stuff blows though the cap, yep, it will be in contact with the small hole drilled though the center of the cap. But that would just slowly go after the center of the cap and the bleed valve. That's much better than having thread failure and that big cap and filter turning into a 5000psi propelled projectile!!

Here is a picture of what you have to do to a ShoeBox to connect the large brass Diablo fitting provided.

Look at how much better the JBA foster connects. Sigh. Hind sight is 20 / 20.

Here is the Diablo with only stage 1 compressor pressure - air always flowing.

http://vid1376.photobucket.com/albums/ah25/B_Scott_Harroff/IMG_2126_zpsml5oi7ii.mp4

here is the JBA - same test - except the JBA is being driven at 1700 psi from the ShoeBox - the check valvle is just starting to open a bit.

http://vid1376.photobucket.com/albums/ah25/B_Scott_Harroff/IMG_2134_zpsun1fxhrl.mp4

So why do we care about the above. Ok, pick up a pack of normal packing gel. Blow over it with your breath. How much moisture do you think it removed. Now put that in a tube and again with your breath blow though it. How much did it remove? More? Yep.

Now - don't do this at home cause I'm a professionally trained nut - blow though the Diable. How much moisture was removed. More than the straw? Yep. Did it get all of it? Nope.

Now - don't do this at home cause I'm a professionally trained nut - blow though the JBA. What do you mean you can't???? Try again. Same result? What's up? The JBA's check valve needs atleast 1700 psi (on mine) to open.

So as the air is flowing aroung the beads in the Diablo, it's being forced to 1700 psi in the JBA before it can leave. The more pressure, the more the air is forced to interact with the desicant meaning the more moisture is removed. And by the same token the more is removed by the active charcoal in the JBA. End result should be inferred:

At 0-100 psi, the cleaning of the air is less than 100-250 which is less than 250-500 which is less than 500-1000 which is less than 1000-1700. The air going into your tank from the Diablo on the first half of your filling isn't going to be as clean and dry as the air that starts leaking into your tank from the JBA starting at 1700 psi. That's a big difference on cleaning the first half of the air going into your tanks, folks!

Here is my stage 1 - a 200 psi 15 gallon compressor in a room at 60 degrees and 30 percent humidity via a dehumidifier.

I started off with an empty Tigershark and filled it to 4500 psi. Here is the water and stuff removed by stage 1 - a couple of teaspoons

Here is what I bled off from the JBA at the end - a couple of drops of water and residue from high compression.

I have cool dry air (30% humidity) going into a large tank at 200 psi. I still wound up with drops of water and high pressure 'stuff' on the other end of my shoebox. For you folks with no filter/dryers, that's going into your tanks/guns.

So to wrap this up, I'm not saying the Diablo is bad (other than mine exploded on its first fill at 500 psi). I am saying I think the JBA is better than the Diablo though.

Is the JBA worth the difference? Depends on who you are and what you want. Some folks are really happy with getting a Mrod and customizing. Others are paying a big difference for a Daystate or FX. Some folks aren't even using a dryer on their compressors and pumps.

I'm keeping my JBA!!!

Upvote 0

WOW! Thanks for the great reveiw Sharroff. The JBA is a much better design. Well worth the difference in price to me.

Upvote 0

The JBA comes with a hose to connect to the compressor with a standard female foster - it was in my pics.

I am fairly confident I could remove the desiccant from the cartridge and bake the desiccant to remove moisture then reuse the filter. Haven't tried yet though.

I am fairly confident I could remove the desiccant from the cartridge and bake the desiccant to remove moisture then reuse the filter. Haven't tried yet though.

Upvote 0

Cool thanks! So it doesn't say anything in the instructions about replacing or recharging the filter?

Upvote 0