In a recent thread several Alkin W31 owners discussed how much they like this compressor. The only issue is that some feel the factory hose is heavy and the bleed lever can be confusing to operate

The problem is that the owner's manual is unclear regarding terminology and correct order of opening and closing valves and the bleed lever. The fittings on the factory hose are designed primarily for shops that fill multiple dive tanks at one session. Most of us have used bleed screws which depressurizes an entire hose. The bleed lever is confusing until the operator understands that it is purposely designed for multiple tank fills. There is a procedure to bleed pressure from the hose above the lever assembly but it requires knowledge of how the lever operates. This is not explained in the owners manual.

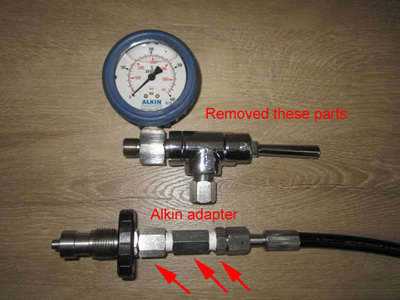

The Alkin home office is very receptive to owner feedback. I called them last week and they sent me an adapter that replaces the 1.75 pound gauge and air bleed lever assembly from the factory fill hose. Most, but not all tanks have valves with gauges and air bleeds. Here is a picture of my Alkin fill hose before and after it was modified to remove parts I don't need since they are also on the tank valve.

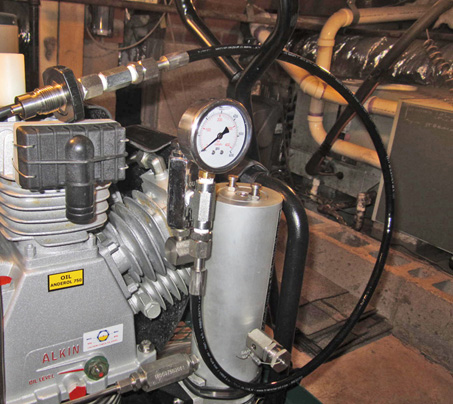

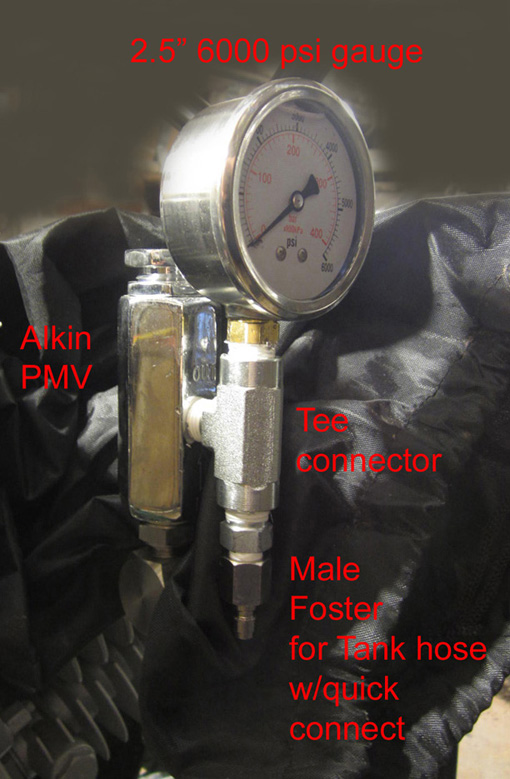

I modified my Alkin by adding a Tee connector and 6000 psi gauge to the PMV. The factory hose attached to the PMV via a male 1/4 NPT threaded adapter. I bought a Tee connector with a male thread 1/4 NPT connection to the PMV. It is mounted vertically with 1/4 NPT female thread on each output side. There is a 2.5" 6000 psi pressure gauge on top of the Tee, and the option of using a 1/4 NPT to 1/8 NPT reduction fitting to a Male Foster, or the factory hose can be threaded on the bottom of the Tee.

The photos below show the compressor in both Foster connector or factory hose configurations. The advantage of the male Foster is that any tank hose with a quick connect can snap on directly to the compressor for a fill. The advantage of the factory hose is that the DIN 300 connection is more secure than a Foster. With either connector I now look up at the compressor gauge to see fill pressure and now have a much lighter hose assembly. The compressor gauge and tank gauge both show the same pressure so both are calibrated correctly.

The Tee connector is $10.50 delivered on Ebay and the pressure gauge is $13.68 delivered on Amazon.

The problem is that the owner's manual is unclear regarding terminology and correct order of opening and closing valves and the bleed lever. The fittings on the factory hose are designed primarily for shops that fill multiple dive tanks at one session. Most of us have used bleed screws which depressurizes an entire hose. The bleed lever is confusing until the operator understands that it is purposely designed for multiple tank fills. There is a procedure to bleed pressure from the hose above the lever assembly but it requires knowledge of how the lever operates. This is not explained in the owners manual.

The Alkin home office is very receptive to owner feedback. I called them last week and they sent me an adapter that replaces the 1.75 pound gauge and air bleed lever assembly from the factory fill hose. Most, but not all tanks have valves with gauges and air bleeds. Here is a picture of my Alkin fill hose before and after it was modified to remove parts I don't need since they are also on the tank valve.

I modified my Alkin by adding a Tee connector and 6000 psi gauge to the PMV. The factory hose attached to the PMV via a male 1/4 NPT threaded adapter. I bought a Tee connector with a male thread 1/4 NPT connection to the PMV. It is mounted vertically with 1/4 NPT female thread on each output side. There is a 2.5" 6000 psi pressure gauge on top of the Tee, and the option of using a 1/4 NPT to 1/8 NPT reduction fitting to a Male Foster, or the factory hose can be threaded on the bottom of the Tee.

The photos below show the compressor in both Foster connector or factory hose configurations. The advantage of the male Foster is that any tank hose with a quick connect can snap on directly to the compressor for a fill. The advantage of the factory hose is that the DIN 300 connection is more secure than a Foster. With either connector I now look up at the compressor gauge to see fill pressure and now have a much lighter hose assembly. The compressor gauge and tank gauge both show the same pressure so both are calibrated correctly.

The Tee connector is $10.50 delivered on Ebay and the pressure gauge is $13.68 delivered on Amazon.