A quick PSA for those of you who have an Air Venturi compressor.

After approximately 20 hours use, I did the required first oil/air-filter change. While the Air Filter was just like new, the oil was completely spent. In 20 hours, the compressor turned high quality synthetic 5w40, (Penzoil Platinum Synthetic) into this green sludge:

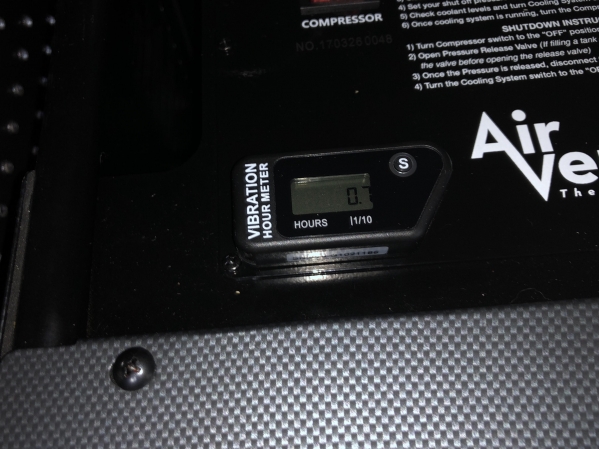

I also added this simple vibration hour-meter to keep track of the future changes. You can pick these up on Amazon for $20 and they work perfectly.

Given the oil breakdown, I might continue doing it at 20-30 hours instead of the recommended 50 hours. For those of you who are wondering, my Air Venturi compressor is still running like a champ and I absolutely love it. Highly recommend this great product

After approximately 20 hours use, I did the required first oil/air-filter change. While the Air Filter was just like new, the oil was completely spent. In 20 hours, the compressor turned high quality synthetic 5w40, (Penzoil Platinum Synthetic) into this green sludge:

I also added this simple vibration hour-meter to keep track of the future changes. You can pick these up on Amazon for $20 and they work perfectly.

Given the oil breakdown, I might continue doing it at 20-30 hours instead of the recommended 50 hours. For those of you who are wondering, my Air Venturi compressor is still running like a champ and I absolutely love it. Highly recommend this great product