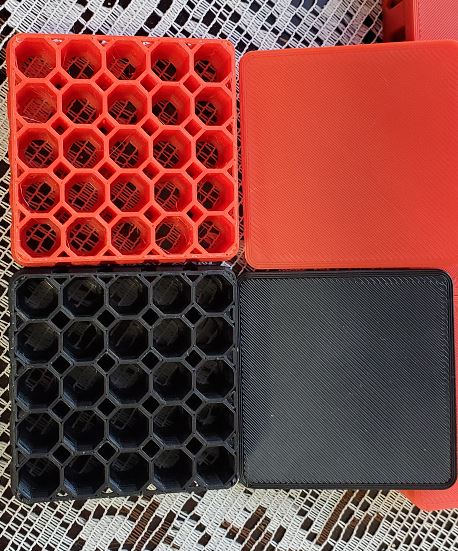

These are prototypes but most are turning out pretty good. Printed in high temperature ABS so they won't warp if left in a car on a hot summer day. I'm thinking about printing more and putting them in the want ad section, as I think I have the design more dialed in. I have them parameterized for diameter, height, and boat tail diameter. I also have some colums for shoting at the range so you can elevate 1, 5, etc. slugs. I can also do any NxN configuration, and have done 7x7 and 10x10, but they are ridiculously big for the .357.

What do you guys think? Too many? I still need to find a place to shoot (western suburbs of the Twin Cities in MN).

What do you guys think? Too many? I still need to find a place to shoot (western suburbs of the Twin Cities in MN).