Hi all,

One of our local designers -Crown shooter himself- some weeks ago came up with various modelling of an alternative linear hammer spring wheel for the FX Crown.

Reacting to a topic on a Dutch forum, he designed and produced not one wheel model, but 3 at once.

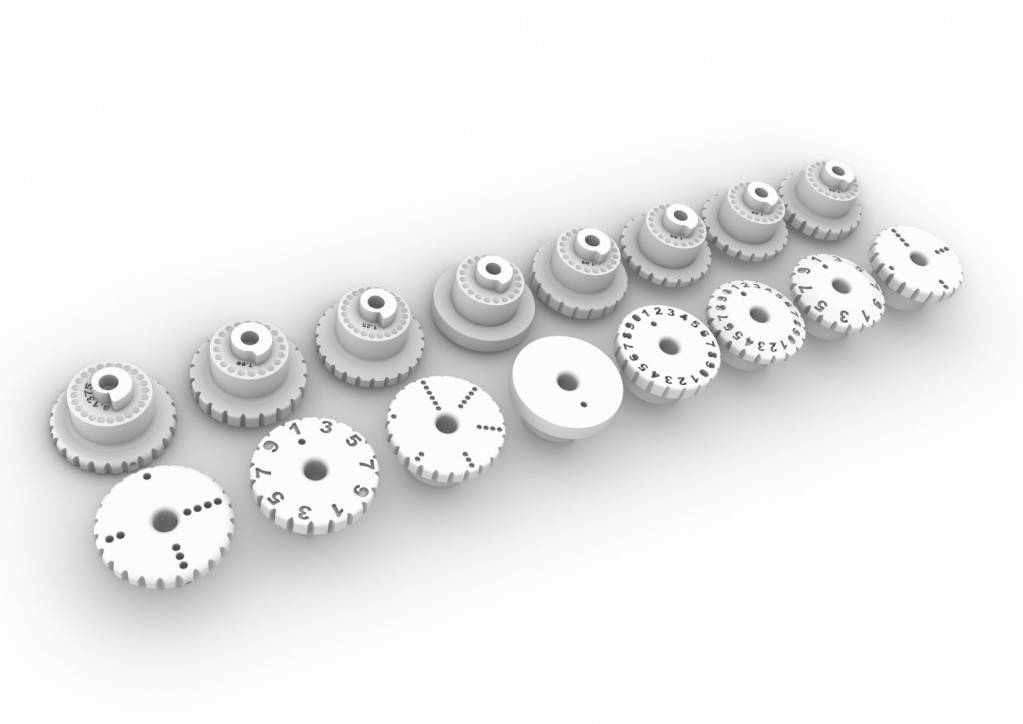

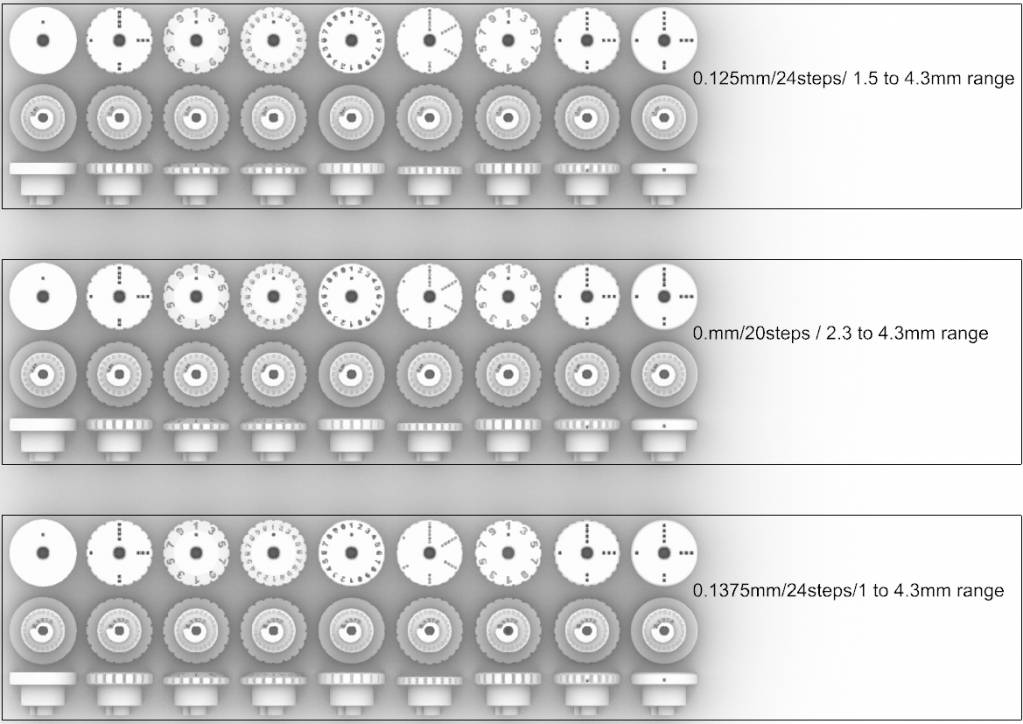

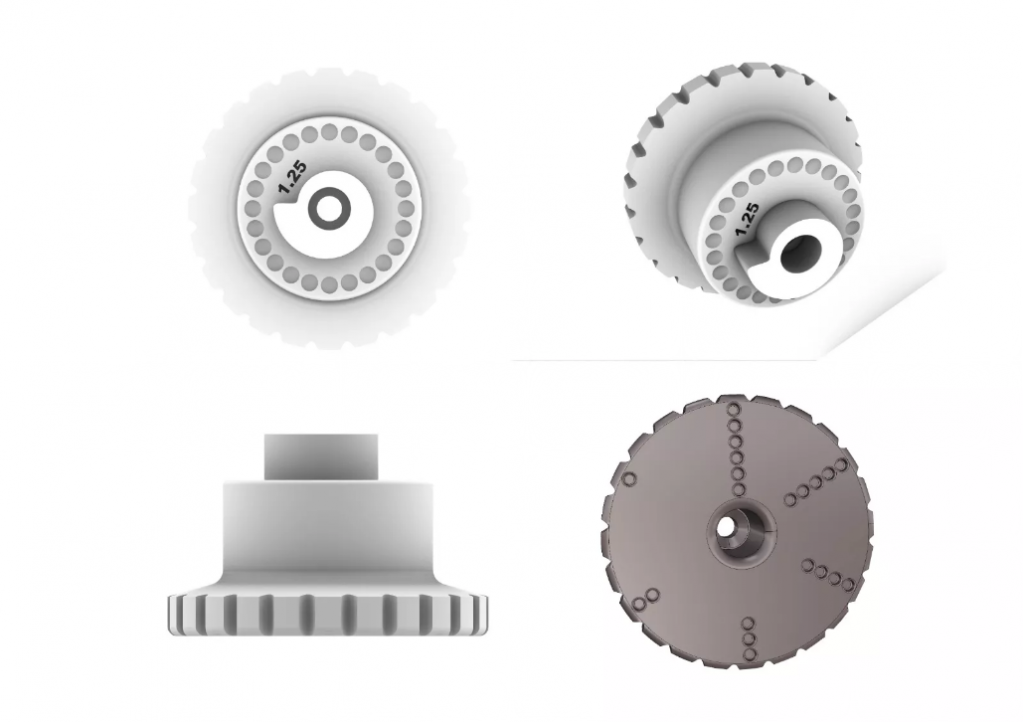

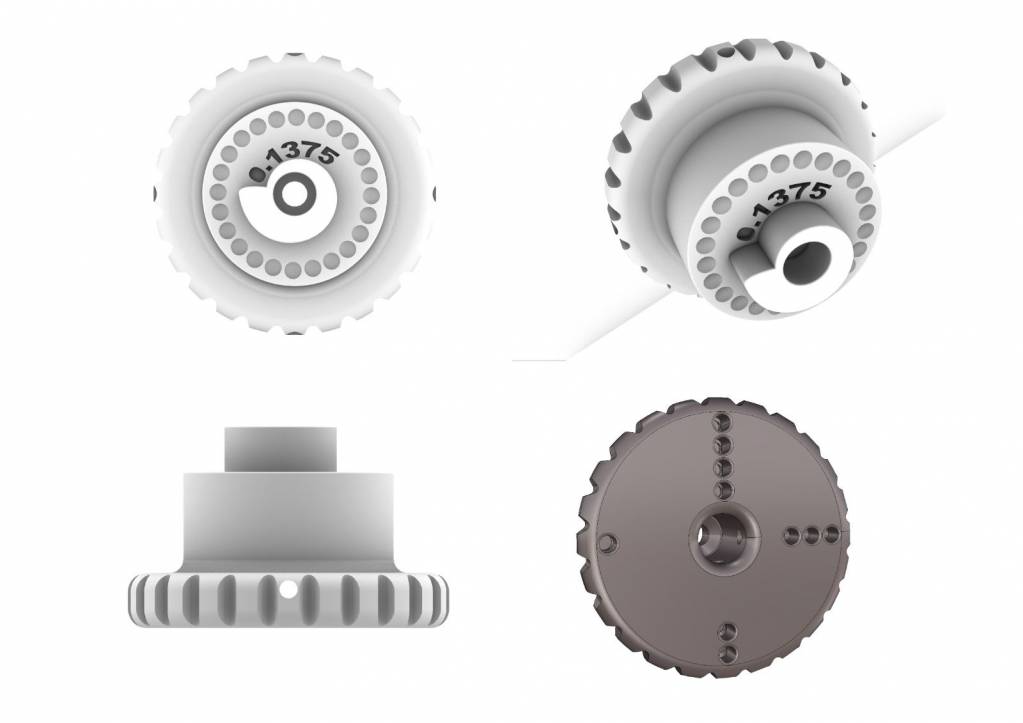

All three wheels with their varying technical specifications for specific use, depending on whether you re shooting .177 sub12 , a .30, or anything in between. At the same time all of those 3 technically varying structures made available in “9 faces”. Shown below.

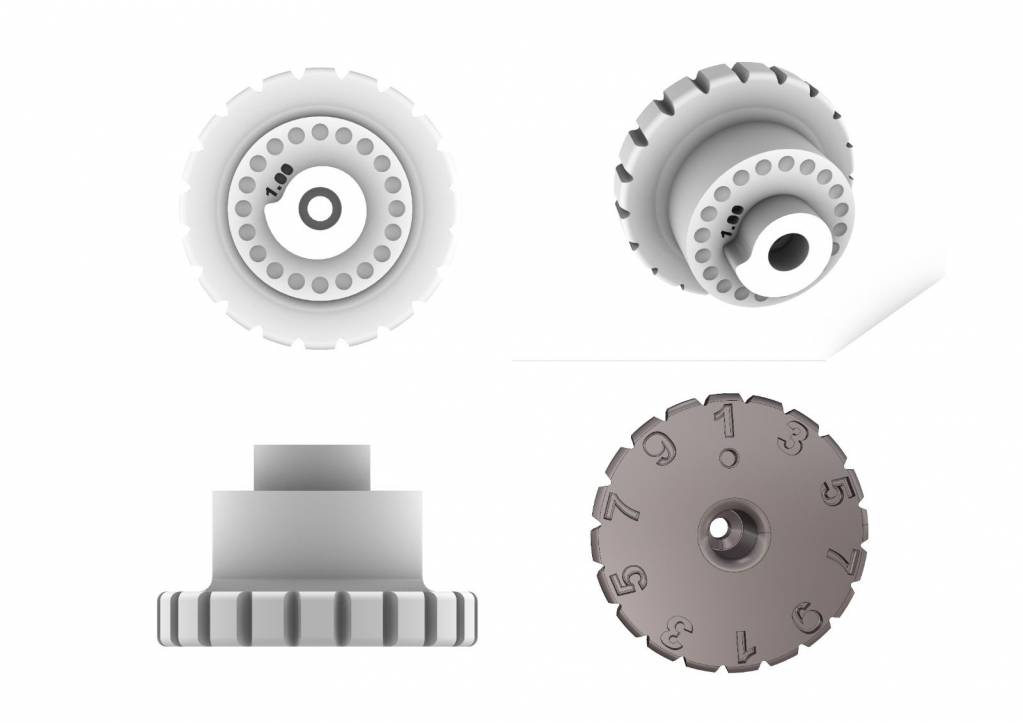

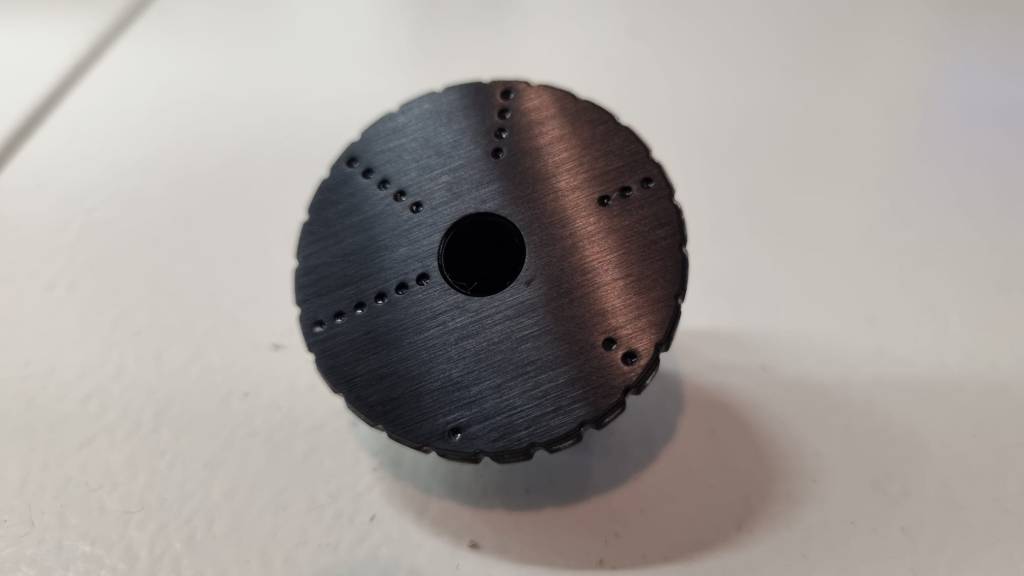

Didn't have to think twice and ordered all three variations. Resin printed they may be, they however look astonishingly ‘sturdy’ and durable. Very sharp detailed make out also.

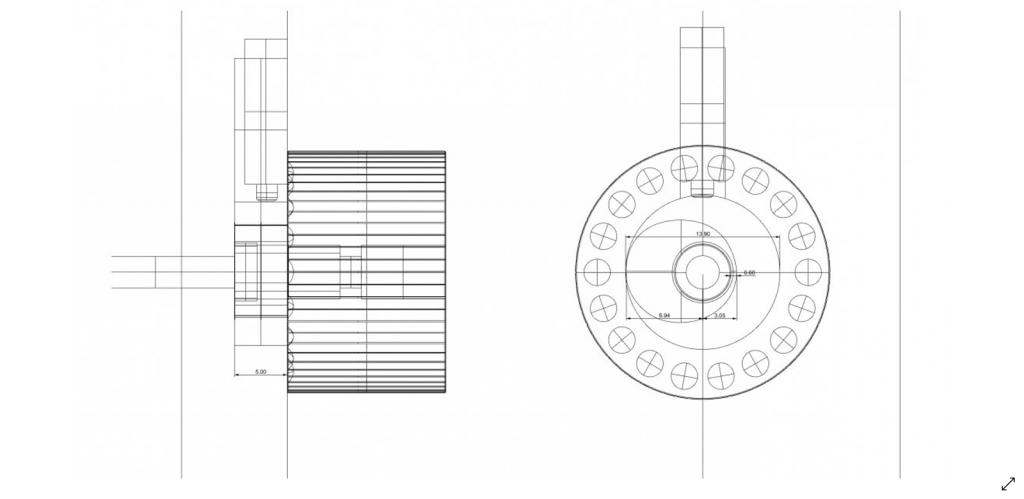

Some design drawnings of the 3 wheels of my choosing.

This is how detailed the real thing looks.

All looks very promising and fine tuning with these wheels apparently makes a lot of difference, But still have to try them out myself.

I ll get to it as soon as the dreary weather will allow my chrony some of the slight sunshine it needs to work at its best.

One of our local designers -Crown shooter himself- some weeks ago came up with various modelling of an alternative linear hammer spring wheel for the FX Crown.

Reacting to a topic on a Dutch forum, he designed and produced not one wheel model, but 3 at once.

All three wheels with their varying technical specifications for specific use, depending on whether you re shooting .177 sub12 , a .30, or anything in between. At the same time all of those 3 technically varying structures made available in “9 faces”. Shown below.

Didn't have to think twice and ordered all three variations. Resin printed they may be, they however look astonishingly ‘sturdy’ and durable. Very sharp detailed make out also.

Some design drawnings of the 3 wheels of my choosing.

This is how detailed the real thing looks.

All looks very promising and fine tuning with these wheels apparently makes a lot of difference, But still have to try them out myself.

I ll get to it as soon as the dreary weather will allow my chrony some of the slight sunshine it needs to work at its best.