Being cheap sometimes, I had to start this way, But once the YH craps out I will upgrade to an Alkin or similar. Keeping a lookout for a good used one.

I did a lot of reading before I bought the YONG HENG compressor and tried to keep track of some of the mods I thought would be useful. I know there were 3 or more people that added some type of cooling to the 2 high pressure tubes, I tried the wet rag thing because it was easy. It didn't take long to discover that the pressure nuts were not stainless and they started to rust so that had to go. Copper tubing wrapped is way to hard for me and some of the heat sinks were out of control. I came up with water jackets, so far they are an noticeable improvement. The best would be to start the cooling right at the compression nuts but that turned out not to be practical due to rust. I started off by just cooling the tubes on the straight section and I managed to burn a finger testing the tube temperature. I moved the cooling tubes around one bend of the tubes and in spite of the kinking it still works very well. The Nuts still get HOT.

While I had the cover off I replaced the paddle wheel fan with one from eBay. The new fan blows a lot more air and if you do this you will not need an external fan. The only fans I found all had a 13mm hole and the YH motor shaft is 14.1mm. I just drilled the fan out to 14mm and forced it on. Once drilled the fan no longer had a flat to fit the shaft and worst case I could use a set screw to keep it from spinning - not to worry! at 14mm it fits tight. The old fan is held on with a snap ring and glue it took some effort but it comes off without special tools.

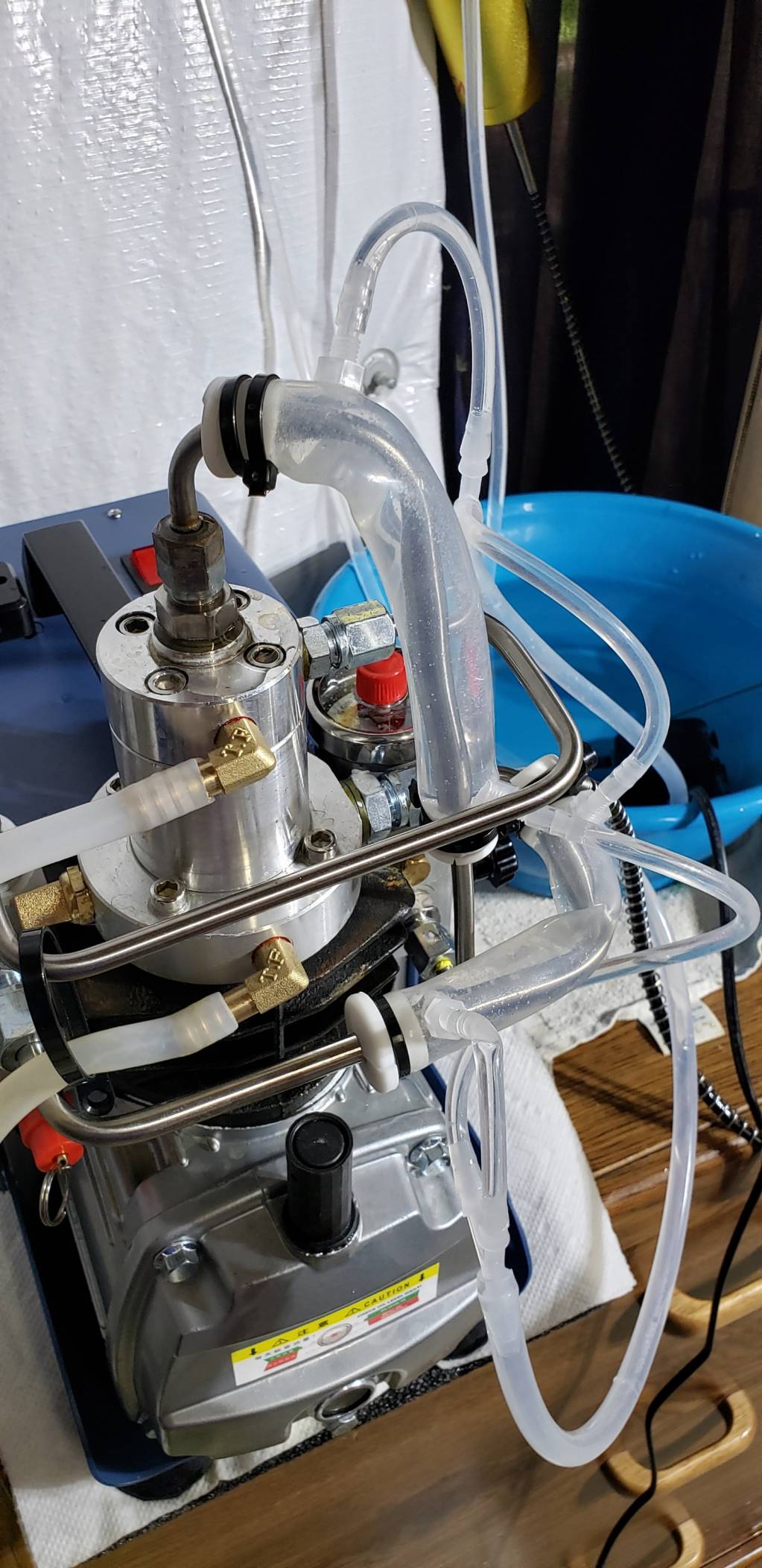

I used an 800 lpm upgraded water pump for the main cooling and I had the stock pump as a back-up, for testing this is what I used for the water jackets.

I think the pictures tell the story.

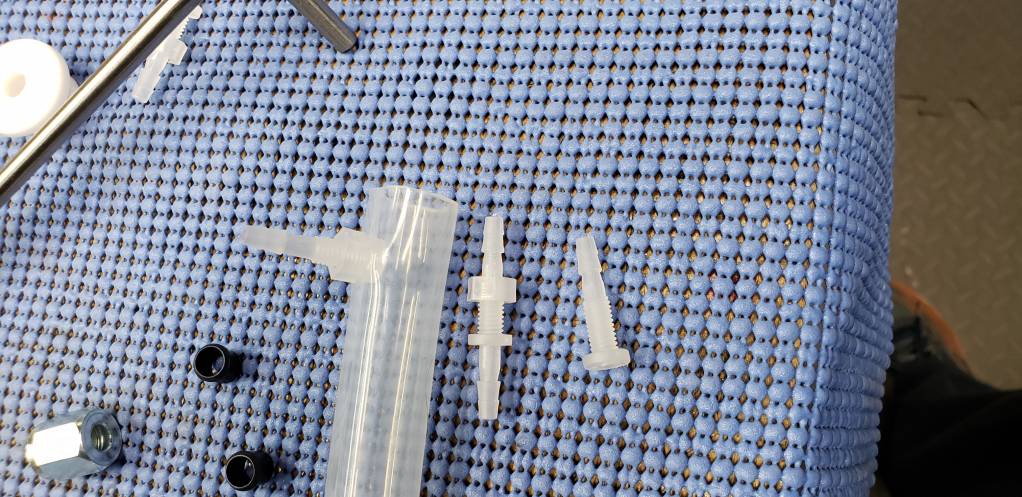

Most of the parts:

I had a new high pressure tube that I was sent because I couldn't get a leak stopped on the original. Different story. I ended up reusing the old one because I wrecked one of the new seals (I'd like to know where I can get one (6mm furrel) without buying the complete YH tube set.) I did get the old HP tube to seal.

The old fan. I forgot to take one of the new fan installed.

The High and medium pressure tubes need to be removed. Careful! Use the longest open-end wrenches you can, as near as I can tell they are all metric but none of them fit great... This can be quite a task, just remember you will need to put it back together. 2 wrenches there is no need to remove the adapters screwed into the heads and water separators.

The bulkhead fittings need to be cut, be sure to cut off the end without the threads. Leave the flat side smooth, a Dremel with a cut-off wheel works great. Then cut the 18mm tubing to size. I could have made mine longer I hadn't planed to go around corners. With the size I have when running the HP tubes are cool below the jacket.

The holes for the bulk head fittings need to be punched not cut or drilled or you take a chance of splitting the tube when inserting or tightening the bulkhead nuts.I think I used 5/32", look for a snug fit. The holes should be at the ends leaving room to insert the plugs without interference.

Then you can stretch, push and pull the 18mm tube over the compression nut to get them on the tubes. Do Not remove the seals & nuts from the tubes unless you are looking for trouble. Once that's done insert the bulkhead fittings and put the nuts on. With silicone finger tight is plenty we do not plan to use high pressure water. The plugs with 6mm holes go on the high pressure tube coming from the top and the ones with 8mm hole go on the medium pressure tube (but you already knew that). The plugs get cut in order to get them on the tubes. Use a razor blade or hobby knife with a new blade, cut from top to bottom and don't cut them into 2 pieces.

Pry them apart and slip around the tubes, at this point there is no reason to insert them into the tubes. Put them on so you end up similar to the next picture. I took pictures thinking I was installing them on the straight sections and didn't get any before shots going around the bends. In fact once the silicone tubes are over the compression nuts you can reinstall the pressure tubes. I had one end of the High pressure line that was being uncooperative and I ended up taking out the 2 screws holding on the HP water separator in order to get the compression nut started without cross threading. Once it was on and snug I reattached the water separator.

Once everything is back together and made to fit around the tubes use wire ties to seal the 18mm silicone tubes to the silicone plugs. use 1/8" or 3/64" and use 2 per plug offsetting the ends. I started off with 1/4" ties but a couple of them leaked because they didn't curve enough to seal all the gaps especially with the 15.5mm OD plugs and 16mm ID tube. The 6mm ID plugs only come in a 15.5mm OD so the fit is not as good but that's all I could find. Metal Screw type hose clamps will damage the silicone tube. There may be other type hose clamps that will do the job but this is what I had.

The water on the head is left over from leak checking.

I used the 6mm tube from the pump to the 'Y' and again back to the drain. 4mm tube from the 'Y' to each section of the water jackets. I ran them in parallel to use the same temp water entering each section.

The water flows from bottom to top so that most of the air is forced out the drain.

Yes after checking for leaks I 'cleaned up' the routing of the water lines.

The test after checking for leaks everywhere was to fill my big tank from ~3600PSI to 4400PSI. I used 2 gal of water in the main pump and 1 gal for the jackets with the smaller pump (just testing). All water started at 65F, after 10 min the head temp showed 45C and surprising both water containers were 72C, pressure 3950, this includes pumping up the filter. At 15 min the water in both reservoirs was 78F the head was 50C, pressure 4200PSI. I took about a 10 minute break and left the water pumps on. It took about another 8 minutes to complete the fill and the water in both tanks remained equal at 83F. The head temp climbed pretty fast and reached 48C in about 6.5 minutes and reached 50C and stayed there until the last 30 seconds when it reached 52C.

As soon as I pick up some 3/8" 'Y' I plan to run the water jackets with the main cooling system, I'll fill the 5 gal bucket all the way.

I'm still waiting to hear from @biohazardman on the the use of redline water treatment in preventing algae.

Here is the shopping list, Yes some the bits from China took 40 days:

FAN

https://www.ebay.com/itm/391807187452?ssPageName=STRK%3AMEBIDX%3AIT&_trksid=p2060353.m2749.l2649

Pump

https://www.amazon.com/gp/product/B07L54HB83/ref=ppx_yo_dt_b_search_asin_title?ie=UTF8&psc=1

Bulk head fittings

https://www.aliexpress.com/item/1005001454484138.html?spm=a2g0s.12269583.0.0.16c5534f5CX25T

4-6mm with 6mm nut

16mm ID tubing

https://www.aliexpress.com/item/1005001459887615.html?spm=a2g0s.9042311.0.0.16394c4dpyhpGV

16x20mm tube 100cm length

Connecting tubing

https://www.aliexpress.com/item/1005001459885915.html?spm=a2g0s.9042311.0.0.16394c4dpyhpGV

6x8mm tube 100cm length

4x6mm tube 100cm length

'Y' connectors

https://www.aliexpress.com/item/32982997172.html?spm=a2g0s.9042311.0.0.16394c4dpyhpGV

I got the 3.8mm size but the 4.5 or even the 6.4mm size is probably a better choice. Just make sure to adjust the tube size.

Tube splice

https://www.aliexpress.com/item/32988967249.html?spm=a2g0s.9042311.0.0.16394c4dpyhpGV

I got these in case I needed to splice tubes. get the size to fit your tubing.

6mm ID and 8mm ID plugs

https://www.aliexpress.com/item/4000038456880.html?spm=a2g0s.9042311.0.0.16394c4dpyhpGV

SH018 white and SH015.5 white

Wire ties 1/8" or 3/32" wide.

I did a lot of reading before I bought the YONG HENG compressor and tried to keep track of some of the mods I thought would be useful. I know there were 3 or more people that added some type of cooling to the 2 high pressure tubes, I tried the wet rag thing because it was easy. It didn't take long to discover that the pressure nuts were not stainless and they started to rust so that had to go. Copper tubing wrapped is way to hard for me and some of the heat sinks were out of control. I came up with water jackets, so far they are an noticeable improvement. The best would be to start the cooling right at the compression nuts but that turned out not to be practical due to rust. I started off by just cooling the tubes on the straight section and I managed to burn a finger testing the tube temperature. I moved the cooling tubes around one bend of the tubes and in spite of the kinking it still works very well. The Nuts still get HOT.

While I had the cover off I replaced the paddle wheel fan with one from eBay. The new fan blows a lot more air and if you do this you will not need an external fan. The only fans I found all had a 13mm hole and the YH motor shaft is 14.1mm. I just drilled the fan out to 14mm and forced it on. Once drilled the fan no longer had a flat to fit the shaft and worst case I could use a set screw to keep it from spinning - not to worry! at 14mm it fits tight. The old fan is held on with a snap ring and glue it took some effort but it comes off without special tools.

I used an 800 lpm upgraded water pump for the main cooling and I had the stock pump as a back-up, for testing this is what I used for the water jackets.

I think the pictures tell the story.

Most of the parts:

I had a new high pressure tube that I was sent because I couldn't get a leak stopped on the original. Different story. I ended up reusing the old one because I wrecked one of the new seals (I'd like to know where I can get one (6mm furrel) without buying the complete YH tube set.) I did get the old HP tube to seal.

The old fan. I forgot to take one of the new fan installed.

The High and medium pressure tubes need to be removed. Careful! Use the longest open-end wrenches you can, as near as I can tell they are all metric but none of them fit great... This can be quite a task, just remember you will need to put it back together. 2 wrenches there is no need to remove the adapters screwed into the heads and water separators.

The bulkhead fittings need to be cut, be sure to cut off the end without the threads. Leave the flat side smooth, a Dremel with a cut-off wheel works great. Then cut the 18mm tubing to size. I could have made mine longer I hadn't planed to go around corners. With the size I have when running the HP tubes are cool below the jacket.

The holes for the bulk head fittings need to be punched not cut or drilled or you take a chance of splitting the tube when inserting or tightening the bulkhead nuts.I think I used 5/32", look for a snug fit. The holes should be at the ends leaving room to insert the plugs without interference.

Then you can stretch, push and pull the 18mm tube over the compression nut to get them on the tubes. Do Not remove the seals & nuts from the tubes unless you are looking for trouble. Once that's done insert the bulkhead fittings and put the nuts on. With silicone finger tight is plenty we do not plan to use high pressure water. The plugs with 6mm holes go on the high pressure tube coming from the top and the ones with 8mm hole go on the medium pressure tube (but you already knew that). The plugs get cut in order to get them on the tubes. Use a razor blade or hobby knife with a new blade, cut from top to bottom and don't cut them into 2 pieces.

Pry them apart and slip around the tubes, at this point there is no reason to insert them into the tubes. Put them on so you end up similar to the next picture. I took pictures thinking I was installing them on the straight sections and didn't get any before shots going around the bends. In fact once the silicone tubes are over the compression nuts you can reinstall the pressure tubes. I had one end of the High pressure line that was being uncooperative and I ended up taking out the 2 screws holding on the HP water separator in order to get the compression nut started without cross threading. Once it was on and snug I reattached the water separator.

Once everything is back together and made to fit around the tubes use wire ties to seal the 18mm silicone tubes to the silicone plugs. use 1/8" or 3/64" and use 2 per plug offsetting the ends. I started off with 1/4" ties but a couple of them leaked because they didn't curve enough to seal all the gaps especially with the 15.5mm OD plugs and 16mm ID tube. The 6mm ID plugs only come in a 15.5mm OD so the fit is not as good but that's all I could find. Metal Screw type hose clamps will damage the silicone tube. There may be other type hose clamps that will do the job but this is what I had.

The water on the head is left over from leak checking.

I used the 6mm tube from the pump to the 'Y' and again back to the drain. 4mm tube from the 'Y' to each section of the water jackets. I ran them in parallel to use the same temp water entering each section.

The water flows from bottom to top so that most of the air is forced out the drain.

Yes after checking for leaks I 'cleaned up' the routing of the water lines.

The test after checking for leaks everywhere was to fill my big tank from ~3600PSI to 4400PSI. I used 2 gal of water in the main pump and 1 gal for the jackets with the smaller pump (just testing). All water started at 65F, after 10 min the head temp showed 45C and surprising both water containers were 72C, pressure 3950, this includes pumping up the filter. At 15 min the water in both reservoirs was 78F the head was 50C, pressure 4200PSI. I took about a 10 minute break and left the water pumps on. It took about another 8 minutes to complete the fill and the water in both tanks remained equal at 83F. The head temp climbed pretty fast and reached 48C in about 6.5 minutes and reached 50C and stayed there until the last 30 seconds when it reached 52C.

As soon as I pick up some 3/8" 'Y' I plan to run the water jackets with the main cooling system, I'll fill the 5 gal bucket all the way.

I'm still waiting to hear from @biohazardman on the the use of redline water treatment in preventing algae.

Here is the shopping list, Yes some the bits from China took 40 days:

FAN

https://www.ebay.com/itm/391807187452?ssPageName=STRK%3AMEBIDX%3AIT&_trksid=p2060353.m2749.l2649

Pump

https://www.amazon.com/gp/product/B07L54HB83/ref=ppx_yo_dt_b_search_asin_title?ie=UTF8&psc=1

Bulk head fittings

https://www.aliexpress.com/item/1005001454484138.html?spm=a2g0s.12269583.0.0.16c5534f5CX25T

4-6mm with 6mm nut

16mm ID tubing

https://www.aliexpress.com/item/1005001459887615.html?spm=a2g0s.9042311.0.0.16394c4dpyhpGV

16x20mm tube 100cm length

Connecting tubing

https://www.aliexpress.com/item/1005001459885915.html?spm=a2g0s.9042311.0.0.16394c4dpyhpGV

6x8mm tube 100cm length

4x6mm tube 100cm length

'Y' connectors

https://www.aliexpress.com/item/32982997172.html?spm=a2g0s.9042311.0.0.16394c4dpyhpGV

I got the 3.8mm size but the 4.5 or even the 6.4mm size is probably a better choice. Just make sure to adjust the tube size.

Tube splice

https://www.aliexpress.com/item/32988967249.html?spm=a2g0s.9042311.0.0.16394c4dpyhpGV

I got these in case I needed to splice tubes. get the size to fit your tubing.

6mm ID and 8mm ID plugs

https://www.aliexpress.com/item/4000038456880.html?spm=a2g0s.9042311.0.0.16394c4dpyhpGV

SH018 white and SH015.5 white

Wire ties 1/8" or 3/32" wide.