So you might have figured it right, as i'm too late on the PCP AND the FX Airguns boat.

My country laws restrict me to .177 so was bound to that Cal.

Kalibrgun products are not available here so my next option was FX (and want too).

Impact was again not my choice as i was looking for a compact option.

So i got the Maverick Compact in .177 bundled the order with Scope, a Hand-pump (yeah, You can give me some slagging there), and a suppressor.

In excitement, even though i noticed during unpackaging, the Bottle adaptor housing a little misaligned, but since Mr. Ernest in his video explained one can sort this easily, i moved on to fill it.

And i filled it to over 220 bars doing 25 pumps in a go repeating no idea how many times, all drenched in sweat, the excitement was still ON.

Filled the cartridge, and loaded, Safety off, and pulled the trigger and everything after took a down-town road including my excitement.

**It was a possible Regulator/Valve lock, nothing happened....

did some more shots removing the magazine, and the first pellet didn't wanna move at all.

And i didn't stop. kept dry firing and reaching over 100 some shots this pellet shoots out into the pellet trap with a good sound leaving a flat foil of what it was made up of.

I never knew i should have been sequential at the fills and shots...**

**Edit Note to above: This was because of the Hammer Limit Screw that actually needs to be removed before beginning to shoot; it's there to avoid hammer hit to Valve during shipment. This i never realized, neither this was in the user manual i read no numbers on how many times...

And then i wrapped it in the very good hard case it came with, for the next weekend, to mount the scope, zeroing and fun-run...

Mid-week i got the scuba tank and filling kit, the hand-pump experience actually took away some seal of itself and much of my enthusiasm of "pressure"-training my Triceps.

Saturday, and by noon i was all in zeroed at 30m (No-Wind), but Matt Dubber's launch video of Maverick didn't leave me settled with 30m.

The 89cc power-plenum did dug in me deep, a lot can be extracted out of this setup.

So Factory Tune (As received):

Main Reg: 120 Bar

Second Reg: 90 Bar

Happy PowerWheel: 7

Adjustment Screw: 3.5 turns out

Re-Tuned the following week:

Main Reg: 140 Bar

Second Reg: 110 Bar

Happy PowerWheel: 6

Adjustment Screw: 4.5 turns out

[Above still didn't feel real happy yet!!]

Third Weekend [Sat, 13-Aug-2022!!], Figured out, the hammer-weight was the 10gm.

Built my custom hammer-weights (*Part # C84 Art#19215), 11gm, and another, 13gm.

Re-Tuned (13gm):

Main Reg: 170 Bar

Second Reg: 150 Bar

Happy PowerWheel: 3

Adjustment Screw: 0 turns out.

Voila!! I'd love to be at this tune forever....BUT!!

I decided to utilize Sunday to re-do the zeroing, and doing a future referable DOPE for 25, 30, 50, 75, and if wind didn't interfere, 100 meters.

16gr JSB Beasts do puncher soda cans at 100m, in .177Cal, just to share where i wanted to go...

BUT....

I open the hardcase, and a gaze at the rear gauge takes away my all Sunday-Dreams in a flash... Only 10bar...

Attempted to fill it and could easily hear a hissing sound, and did figure out it was coming out of the barrel....

Looks like i hammered the pin too hard.

But here're the learnings, and i would be glad if You all can add/correct my steps what they could have actually been to not land at the waiting queue for the Seals kit so early:

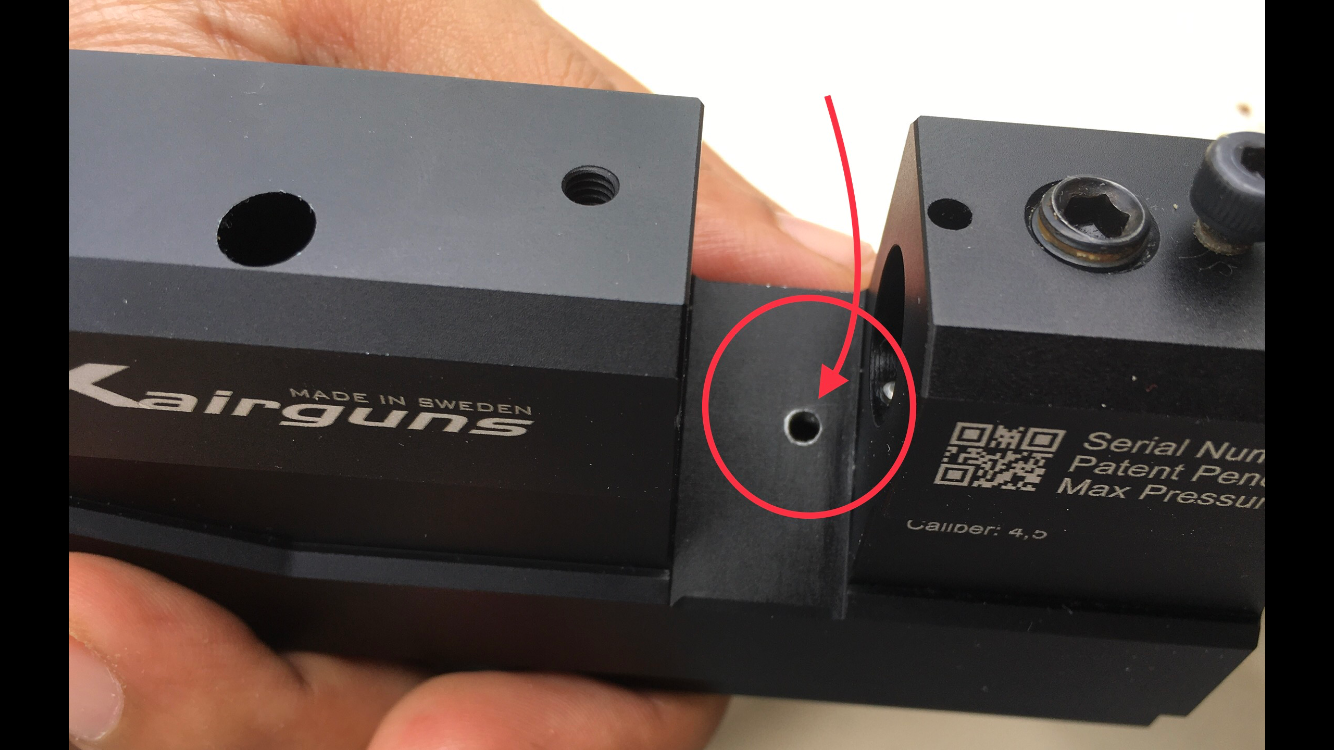

0) Look for the 1.5mm (or 1mm) grub-screw on Main block at the section where Mag slides over and locks. First thing You'd Need to do is to remove it.

Appended Step Zero to begin with, after You unbox Your FX Airgun(s).

1) After unboxing, check and tighten all screws and setups including the Bottle Adaptor, Foster Male connector, the Plenums Assembly from front to Power-block, Poppet Valve Retainer Bolt, both the gauges.

2) It may be possible that the gun was in stock after manufacturing for very long, in my case a Year, so the O-Rings would have hardly any lube left on them and would warrant a replacement/Lube-up before Operation. So Order a Seal kit or ask Your seller to arrange one right with Your order, if possible, with some discounts. As a precaution, lube them with advised silicon grease/oil.

3) While Filling for the first time, past 60-70 bar, pause and fire few dry shots at every 20-30 bar pressure increase. This eases out the regulators in the plenums, especially the second one; You'd easily be able to notice a smoother filling and reliable reading on the second gauge, which otherwise would easily return to a 10-20 bar lower level if You'd simply fill to 250 bar straight. The process also leaves bottle with some time to cool down, even if it's a little bit of heat that gets generated.

4) Using/building a Custom hammer-weight might work out, but use a jewelers scale to weigh it; a 13gm on kitchen scale might be a 13.454 gm on Jeweler's scale.

And by the way, 13gm is way too heavyfor .177 Cal if You don't have the measurement right, including the shape, as the weight placement (distribution) on hammer-weight dictates the momentum it'll gain and pattern it'll keep dumping the energy from spring on the Valve pin, which in turn will increase/decrease the Poppet Valve opening duration (and behavior). A heavier side on the hammer-weight, and You'll end up wasting a lot of air puffing out from the hole below cheek-piece at each shot.

5) A heavier hammer-weight (13gm from slug-kit) might also be very hard on the hammer and its casing (*Part # C83 Art#19039); In attempt to thoroughly check everything after Leak Detection, i found, ***the hammer front edges had signs of flattening out at the chamfers on both slots that are at 180 degrees. Had to file them off to smoothen them back.***

**Edit Note to above: This was caused by the Hammer hitting the Grub Screw i never removed from the main block; Don't do this mistake!

6) PCP Hand-Pump 3/4 stage, if at all You are bound to that option only, pls. pick a good one like that from Hill, Hatsan, Air-Venturi, and while filling stick to following intervals to allow the pump parts get cool & ready for next set of Your triceps workout.

7) FX Airguns are like You need to up-keep on the service side of the machine. It's not that You leave it in the box for months and It is ready to fire on Your next unplanned tour with just a Fill. You literally need to think and work about over 40 pressure seals it's got. And Mann, it's around 30$ to reach me Plus a ~20 Day wait time from E-Bay; See i'm losing at least 4 days of fun in 2 weekends, and the third one into servicing it when the kit arrives...

8) Lastly, If You don't have a chronograph, Your temptation to hit the reactive target harder might lead You to higher pressures setup that in turn will affect the longevity of parts, including but not limited to Seals, Hammer, Poppet Valve assembly, which will be a high-cost thingy, and a waiting-in-queue experience too. So build (It's not that difficult, and i'm collecting electronics to do it) or buy one.

There go my 50 cents and learnings from first ever PCP Owning Experience i BullDozed myself into....

[SoulSniper]

[* see attachment - Maverick Parts - Exploded Views and Art Codes]

View attachment Maverick-1.pdf

My country laws restrict me to .177 so was bound to that Cal.

Kalibrgun products are not available here so my next option was FX (and want too).

Impact was again not my choice as i was looking for a compact option.

So i got the Maverick Compact in .177 bundled the order with Scope, a Hand-pump (yeah, You can give me some slagging there), and a suppressor.

In excitement, even though i noticed during unpackaging, the Bottle adaptor housing a little misaligned, but since Mr. Ernest in his video explained one can sort this easily, i moved on to fill it.

And i filled it to over 220 bars doing 25 pumps in a go repeating no idea how many times, all drenched in sweat, the excitement was still ON.

Filled the cartridge, and loaded, Safety off, and pulled the trigger and everything after took a down-town road including my excitement.

**It was a possible Regulator/Valve lock, nothing happened....

did some more shots removing the magazine, and the first pellet didn't wanna move at all.

And i didn't stop. kept dry firing and reaching over 100 some shots this pellet shoots out into the pellet trap with a good sound leaving a flat foil of what it was made up of.

I never knew i should have been sequential at the fills and shots...**

**Edit Note to above: This was because of the Hammer Limit Screw that actually needs to be removed before beginning to shoot; it's there to avoid hammer hit to Valve during shipment. This i never realized, neither this was in the user manual i read no numbers on how many times...

And then i wrapped it in the very good hard case it came with, for the next weekend, to mount the scope, zeroing and fun-run...

Mid-week i got the scuba tank and filling kit, the hand-pump experience actually took away some seal of itself and much of my enthusiasm of "pressure"-training my Triceps.

Saturday, and by noon i was all in zeroed at 30m (No-Wind), but Matt Dubber's launch video of Maverick didn't leave me settled with 30m.

The 89cc power-plenum did dug in me deep, a lot can be extracted out of this setup.

So Factory Tune (As received):

Main Reg: 120 Bar

Second Reg: 90 Bar

Happy PowerWheel: 7

Adjustment Screw: 3.5 turns out

Re-Tuned the following week:

Main Reg: 140 Bar

Second Reg: 110 Bar

Happy PowerWheel: 6

Adjustment Screw: 4.5 turns out

[Above still didn't feel real happy yet!!]

Third Weekend [Sat, 13-Aug-2022!!], Figured out, the hammer-weight was the 10gm.

Built my custom hammer-weights (*Part # C84 Art#19215), 11gm, and another, 13gm.

Re-Tuned (13gm):

Main Reg: 170 Bar

Second Reg: 150 Bar

Happy PowerWheel: 3

Adjustment Screw: 0 turns out.

Voila!! I'd love to be at this tune forever....BUT!!

I decided to utilize Sunday to re-do the zeroing, and doing a future referable DOPE for 25, 30, 50, 75, and if wind didn't interfere, 100 meters.

16gr JSB Beasts do puncher soda cans at 100m, in .177Cal, just to share where i wanted to go...

BUT....

I open the hardcase, and a gaze at the rear gauge takes away my all Sunday-Dreams in a flash... Only 10bar...

Attempted to fill it and could easily hear a hissing sound, and did figure out it was coming out of the barrel....

Looks like i hammered the pin too hard.

But here're the learnings, and i would be glad if You all can add/correct my steps what they could have actually been to not land at the waiting queue for the Seals kit so early:

0) Look for the 1.5mm (or 1mm) grub-screw on Main block at the section where Mag slides over and locks. First thing You'd Need to do is to remove it.

Appended Step Zero to begin with, after You unbox Your FX Airgun(s).

1) After unboxing, check and tighten all screws and setups including the Bottle Adaptor, Foster Male connector, the Plenums Assembly from front to Power-block, Poppet Valve Retainer Bolt, both the gauges.

2) It may be possible that the gun was in stock after manufacturing for very long, in my case a Year, so the O-Rings would have hardly any lube left on them and would warrant a replacement/Lube-up before Operation. So Order a Seal kit or ask Your seller to arrange one right with Your order, if possible, with some discounts. As a precaution, lube them with advised silicon grease/oil.

3) While Filling for the first time, past 60-70 bar, pause and fire few dry shots at every 20-30 bar pressure increase. This eases out the regulators in the plenums, especially the second one; You'd easily be able to notice a smoother filling and reliable reading on the second gauge, which otherwise would easily return to a 10-20 bar lower level if You'd simply fill to 250 bar straight. The process also leaves bottle with some time to cool down, even if it's a little bit of heat that gets generated.

4) Using/building a Custom hammer-weight might work out, but use a jewelers scale to weigh it; a 13gm on kitchen scale might be a 13.454 gm on Jeweler's scale.

And by the way, 13gm is way too heavyfor .177 Cal if You don't have the measurement right, including the shape, as the weight placement (distribution) on hammer-weight dictates the momentum it'll gain and pattern it'll keep dumping the energy from spring on the Valve pin, which in turn will increase/decrease the Poppet Valve opening duration (and behavior). A heavier side on the hammer-weight, and You'll end up wasting a lot of air puffing out from the hole below cheek-piece at each shot.

5) A heavier hammer-weight (13gm from slug-kit) might also be very hard on the hammer and its casing (*Part # C83 Art#19039); In attempt to thoroughly check everything after Leak Detection, i found, ***the hammer front edges had signs of flattening out at the chamfers on both slots that are at 180 degrees. Had to file them off to smoothen them back.***

**Edit Note to above: This was caused by the Hammer hitting the Grub Screw i never removed from the main block; Don't do this mistake!

6) PCP Hand-Pump 3/4 stage, if at all You are bound to that option only, pls. pick a good one like that from Hill, Hatsan, Air-Venturi, and while filling stick to following intervals to allow the pump parts get cool & ready for next set of Your triceps workout.

7) FX Airguns are like You need to up-keep on the service side of the machine. It's not that You leave it in the box for months and It is ready to fire on Your next unplanned tour with just a Fill. You literally need to think and work about over 40 pressure seals it's got. And Mann, it's around 30$ to reach me Plus a ~20 Day wait time from E-Bay; See i'm losing at least 4 days of fun in 2 weekends, and the third one into servicing it when the kit arrives...

8) Lastly, If You don't have a chronograph, Your temptation to hit the reactive target harder might lead You to higher pressures setup that in turn will affect the longevity of parts, including but not limited to Seals, Hammer, Poppet Valve assembly, which will be a high-cost thingy, and a waiting-in-queue experience too. So build (It's not that difficult, and i'm collecting electronics to do it) or buy one.

There go my 50 cents and learnings from first ever PCP Owning Experience i BullDozed myself into....

[SoulSniper]

[* see attachment - Maverick Parts - Exploded Views and Art Codes]

View attachment Maverick-1.pdf

Last edited: