My YongHeng 110v machine siezed after a couple of months of use amounting to about an hour of total run time. Seller ShareProfit dissapeared from Amazon after refusing my demands for return, replacement or authorized repair. Amazon wouldn't cover it. I bought an extra SquareTrade warrantee which did cover the loss, but only after I had to threaten them with a complaint to my state's Attorney General Consumer Affairs Division. Bottom line. Big headache.

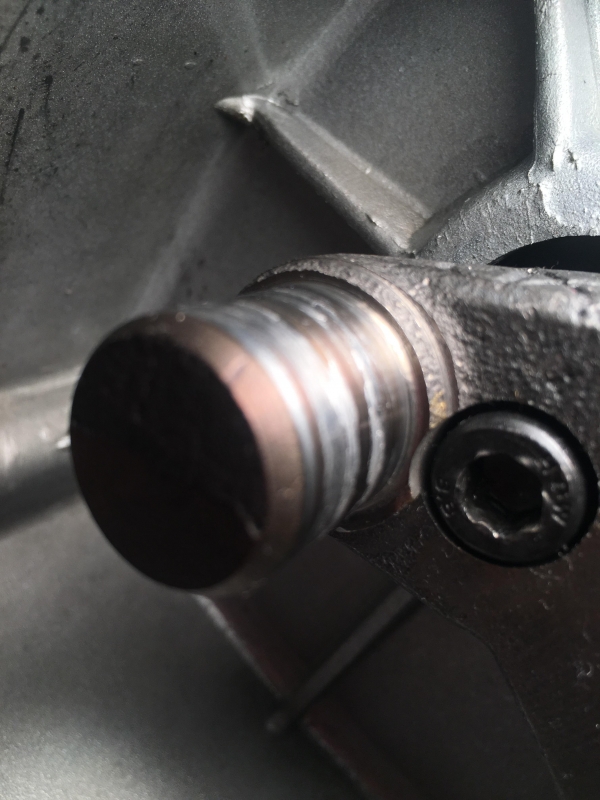

Soooo, now that I have nothing to lose, I decided to take the thing apart. I found the failure point that Joerg Parva (Slingshot Channel) discussed at about the 20:00 mark in his YouTube review https://www.youtube.com/watch?v=7NdnItyJs-U. As Joerg predicted, the aluminum crank arm spalled badly at the connection to the steel main crank resulting in seizure. (pictures attached). I want to note the oil level and condition was good and the cooling system was functioning when the failure happened at about 3800 psi.

I've ordered a new crank arm off AliExpress and plan to try a repair after polishing off the residual aluminum spall melted onto the steel crank connection.

Any advice on how to conduct the polishing and repair would be appreciated.

Soooo, now that I have nothing to lose, I decided to take the thing apart. I found the failure point that Joerg Parva (Slingshot Channel) discussed at about the 20:00 mark in his YouTube review https://www.youtube.com/watch?v=7NdnItyJs-U. As Joerg predicted, the aluminum crank arm spalled badly at the connection to the steel main crank resulting in seizure. (pictures attached). I want to note the oil level and condition was good and the cooling system was functioning when the failure happened at about 3800 psi.

I've ordered a new crank arm off AliExpress and plan to try a repair after polishing off the residual aluminum spall melted onto the steel crank connection.

Any advice on how to conduct the polishing and repair would be appreciated.