My Yong Heng compressor got here yesterday and i’ll be setting it up this weekend. I’ve done a fair amount of research on them and plan on making a station for it this summer, also plan to setup a fan blowing cold air directly to it, but was wondering if anyone had any tips for me or things I should know about it before I setup and start using it. Thanks!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Yong Heng tips?

- Thread starter WyoAirguns

- Start date

There are MANY previous posts on here about care, maintenance, operation, etc. I think a lot of us learned by following the posts, both. present & past. I know I did.

Upvote 0

Use good oil, distilled water + anti-corrosion additive, a decent water + oil separator and you are good to go for a long time.

Run it with no charge 30s to 1min before filling your bottle and don't stop it under pressure. Slowly purge air before stop it.

Run it with no charge 30s to 1min before filling your bottle and don't stop it under pressure. Slowly purge air before stop it.

Upvote 0

Take a tour of the pump section lots of very good information there.

https://www.airgunnation.com/forum/accessories/air-tanks-pumps-compressors-filters/

https://www.airgunnation.com/forum/accessories/air-tanks-pumps-compressors-filters/

Upvote 0

Edited and Current 3/21

Here is my standard post to all things Yong Heng hope it is helpful.

The Yong Heng "Simple" version least expensive does not have a water separator you need one.

The "Auto Stop" version shuts off near 3000psi probly not a good thing for most people.

So you likely want the "Hardcover" or "Set Pressure" versions your choice on the 110V or 220V.

https://www.aliexpress.com/item/32824234795.html?spm=a2g0o.store_home.productList_13760454.subject_2

Keep them cool and filled with oil. ISO 46 may no longer be recommended although I used it for a year without failure. I am currently using the Husky Brand Synthetic or synthetic blend oil, found at Home Depot, for two years now without a problem. Top it off to the red circle in the sight glass.

Don't push your air fill past the compressor’s spec which is 4350psi. A little less is usually better than the max, and the Yong Heng should last for years unless you get a bad one. I did my first oil change at about an hour, it was extremely dark colored. I went far longer, between changes, after that.

I have two YH compressors bought the second as a backup for the first as I, fergot to turn on the coolant pump several times and, overheated it until it smoked. It did not like it but it runs fine. Still I did not trust it after that. I added a switched outlet, to the system, so it turns the pump on before the compressor will power up to keep me from doing that from now on.

The second one, my back up unit, died in about two months bad QC from the factory. Cost me $12 for a new second stage piston and an hours’ time to replace it. Then to add insult to injury I fergot to put oil in, the latest unit after I put it back together, and ran it for a couple of minutes without any. So I filled it with oil and it fired up and somehow still werqs fine. The #1 unit that I was worried about, cuz I overheated it so many times, just kept on filling my guns and tanks till I got #2 repaired and retired it.

I do not fill past 4200psi as when I do, all too often, I blow a burst disc. This may not happen on the first or second fill but soon thereafter it will.

The temperature sensor only measures head temperature so running it much over 20-30 minutes can overheat the motor and other parts even if ice is used in the coolant. Ice or a container of it, in the coolant, is a good idea especially if you are like me and do not use the full five gallons of water as suggested in the manual.

Keep your water supply level with the compressor to be kind to the pump and assure a good supply of coolant goes through the compressor.

I recently started using this Red Line water treatment after I noticed algae growth in my 2.5 gallon water bucket every few months. It seems to have stopped or significantly slowed the algae growth. I will know more in a few months

https://www.autozone.com/antifreeze-radiator-additives-and-windshield-wash-fluid/coolant-water-wetter-additive/red-line-water-wetter-super-coolant-12oz/486218_0_0

Keep your moisture filters, guns and tanks being filled above the compressor to help keep the moisture out.

Purge the system of moisture, using the screw valves on both sides of the compressor, for a couple of seconds every five minutes while in use.

Change out your small YH filter every twenty minutes and set the old one out to dry and use later.

Add a better filter if needed to be sure more moisture and any oil smell is removed from the system. Many of us use this Tuxing three media filter although, if you feel the need, you can change media types at any time.

https://www.aliexpress.com/item/32891898253.html

A smaller one will probly do for some.

https://www.aliexpress.com/item/4000960926898.html?spm=a2g0s.9042311.0.0.2a034c4dL0nrJU

Possibly a filter similar to this if humidity is high in your area and your desiccant filters have to be replaced often.

https://www.ebay.com/itm/30MPa-High-Pressure-Air-Filter-Oil-Water-Separator-For-Air-Pump-Air-Tank/402600939671?hash=item5dbce2d097:g RoAAOSwy41f00pY

RoAAOSwy41f00pY

Bleed the pressure before you turn the unit off and let it run a few seconds to get the better part of the moisture out of the system. I have found that I blow less burst discs if I bleed before shutting down so I do this religiously.

Let the coolant pump run for a few minutes after shutdown to cool things off.

Info on the radiator install.

https://www.airgunnation.com/topic/yet-another-yong-heng-mod/

Testing of the Radiator install.

https://www.airgunnation.com/topic/finally-got-to-test-out-the-yong-heng-mod-i-did

Here is a video on how to fill a SCBA tank.

https://www.youtube.com/watch?time_continue=157&v=_grx5p_R8D4&feature=emb_title

Here is my standard post to all things Yong Heng hope it is helpful.

The Yong Heng "Simple" version least expensive does not have a water separator you need one.

The "Auto Stop" version shuts off near 3000psi probly not a good thing for most people.

So you likely want the "Hardcover" or "Set Pressure" versions your choice on the 110V or 220V.

https://www.aliexpress.com/item/32824234795.html?spm=a2g0o.store_home.productList_13760454.subject_2

Keep them cool and filled with oil. ISO 46 may no longer be recommended although I used it for a year without failure. I am currently using the Husky Brand Synthetic or synthetic blend oil, found at Home Depot, for two years now without a problem. Top it off to the red circle in the sight glass.

Don't push your air fill past the compressor’s spec which is 4350psi. A little less is usually better than the max, and the Yong Heng should last for years unless you get a bad one. I did my first oil change at about an hour, it was extremely dark colored. I went far longer, between changes, after that.

I have two YH compressors bought the second as a backup for the first as I, fergot to turn on the coolant pump several times and, overheated it until it smoked. It did not like it but it runs fine. Still I did not trust it after that. I added a switched outlet, to the system, so it turns the pump on before the compressor will power up to keep me from doing that from now on.

The second one, my back up unit, died in about two months bad QC from the factory. Cost me $12 for a new second stage piston and an hours’ time to replace it. Then to add insult to injury I fergot to put oil in, the latest unit after I put it back together, and ran it for a couple of minutes without any. So I filled it with oil and it fired up and somehow still werqs fine. The #1 unit that I was worried about, cuz I overheated it so many times, just kept on filling my guns and tanks till I got #2 repaired and retired it.

I do not fill past 4200psi as when I do, all too often, I blow a burst disc. This may not happen on the first or second fill but soon thereafter it will.

The temperature sensor only measures head temperature so running it much over 20-30 minutes can overheat the motor and other parts even if ice is used in the coolant. Ice or a container of it, in the coolant, is a good idea especially if you are like me and do not use the full five gallons of water as suggested in the manual.

Keep your water supply level with the compressor to be kind to the pump and assure a good supply of coolant goes through the compressor.

I recently started using this Red Line water treatment after I noticed algae growth in my 2.5 gallon water bucket every few months. It seems to have stopped or significantly slowed the algae growth. I will know more in a few months

https://www.autozone.com/antifreeze-radiator-additives-and-windshield-wash-fluid/coolant-water-wetter-additive/red-line-water-wetter-super-coolant-12oz/486218_0_0

Keep your moisture filters, guns and tanks being filled above the compressor to help keep the moisture out.

Purge the system of moisture, using the screw valves on both sides of the compressor, for a couple of seconds every five minutes while in use.

Change out your small YH filter every twenty minutes and set the old one out to dry and use later.

Add a better filter if needed to be sure more moisture and any oil smell is removed from the system. Many of us use this Tuxing three media filter although, if you feel the need, you can change media types at any time.

https://www.aliexpress.com/item/32891898253.html

A smaller one will probly do for some.

https://www.aliexpress.com/item/4000960926898.html?spm=a2g0s.9042311.0.0.2a034c4dL0nrJU

Possibly a filter similar to this if humidity is high in your area and your desiccant filters have to be replaced often.

https://www.ebay.com/itm/30MPa-High-Pressure-Air-Filter-Oil-Water-Separator-For-Air-Pump-Air-Tank/402600939671?hash=item5dbce2d097:g

Bleed the pressure before you turn the unit off and let it run a few seconds to get the better part of the moisture out of the system. I have found that I blow less burst discs if I bleed before shutting down so I do this religiously.

Let the coolant pump run for a few minutes after shutdown to cool things off.

Info on the radiator install.

https://www.airgunnation.com/topic/yet-another-yong-heng-mod/

Testing of the Radiator install.

https://www.airgunnation.com/topic/finally-got-to-test-out-the-yong-heng-mod-i-did

Here is a video on how to fill a SCBA tank.

https://www.youtube.com/watch?time_continue=157&v=_grx5p_R8D4&feature=emb_title

Upvote 0

Use proper high pressure comp oil. I use shell corena s2 p150.

Get a good water seperator for the fill side. I use a cyclonic coalescing tower with drain spout, which I will crack open once or twice while the compressor is running to bleed off moisture

Go ahead and upgrade your pressure gauge to a better oil filled one

Try not to run it over 50 degrees C, or if you do not for long

Don't run longer than 15 min without giving it a bit of a break

Get a good water seperator for the fill side. I use a cyclonic coalescing tower with drain spout, which I will crack open once or twice while the compressor is running to bleed off moisture

Go ahead and upgrade your pressure gauge to a better oil filled one

Try not to run it over 50 degrees C, or if you do not for long

Don't run longer than 15 min without giving it a bit of a break

Upvote 0

This is what I have used for well over 2 years in mine $8 a quart local Napa store , bought a second at good price just to have in the event this first one does fail, great little compressor

Upvote 0

Tips .. don't flog it to death ..when it warms up to hot give it a rest ...and dont put it away wet .. if you are a daily user nothing you can do, it lasts until its gone and get another one, but if you use it to fill a bottle once a week, take the time to partially break it down and blow it out and protect it including the water jacket and it will last indefinitely .. the oil in the crankcase everybody focuses on is usually not why they fail ... overheating and moisture corrosion damage is ..

Upvote 0

Biohazardman's response is a great template to follow! Above all, HEAT & starting or stopping under pressure is the ENEMY! Get an aquarium pump that's better than the YH pump. Good luck. Had mine for about 6 months to top off my SCBA tanks. Really great to have my own supply of air.

Upvote 0

This is what I have used for well over 2 years in mine $8 a quart local Napa store , bought a second at good price just to have in the event this first one does fail, great little compressor

Can’t go wrong with AMS OIL.

Upvote 0

If it was not already stated: Plug the compressor and the water pump into a corded multi-outlet and then plug that into the wall outlet. This way you will not forget to turn on the water pump. Also make sure that the outlet is not on a circuit that already has a significant load on it (i.e. refridgerator).

$30 cart from Amazon keeps it conveniently mobile.

$30 cart from Amazon keeps it conveniently mobile.

Upvote 0

Thanks for the tips everyone! I should add I bought a new water pump with it that is 800 gph which I think should work well, I also bought a 30Mpa Oil Water Separator that was like 70 bucks. I live in Wyoming so we have basically zero humidity in the air and all my previous compressors have had zero issues with water getting to the gun. I really liked the tip of getting multi outlet plug in so I never forget to plug the pump in before the compressor and thanks for all the advice on oil. Now I just need to find a small tank to fill so I don’t have to always directly fill my gun. Once again thanks everyone!

Upvote 0

One more recommendation:

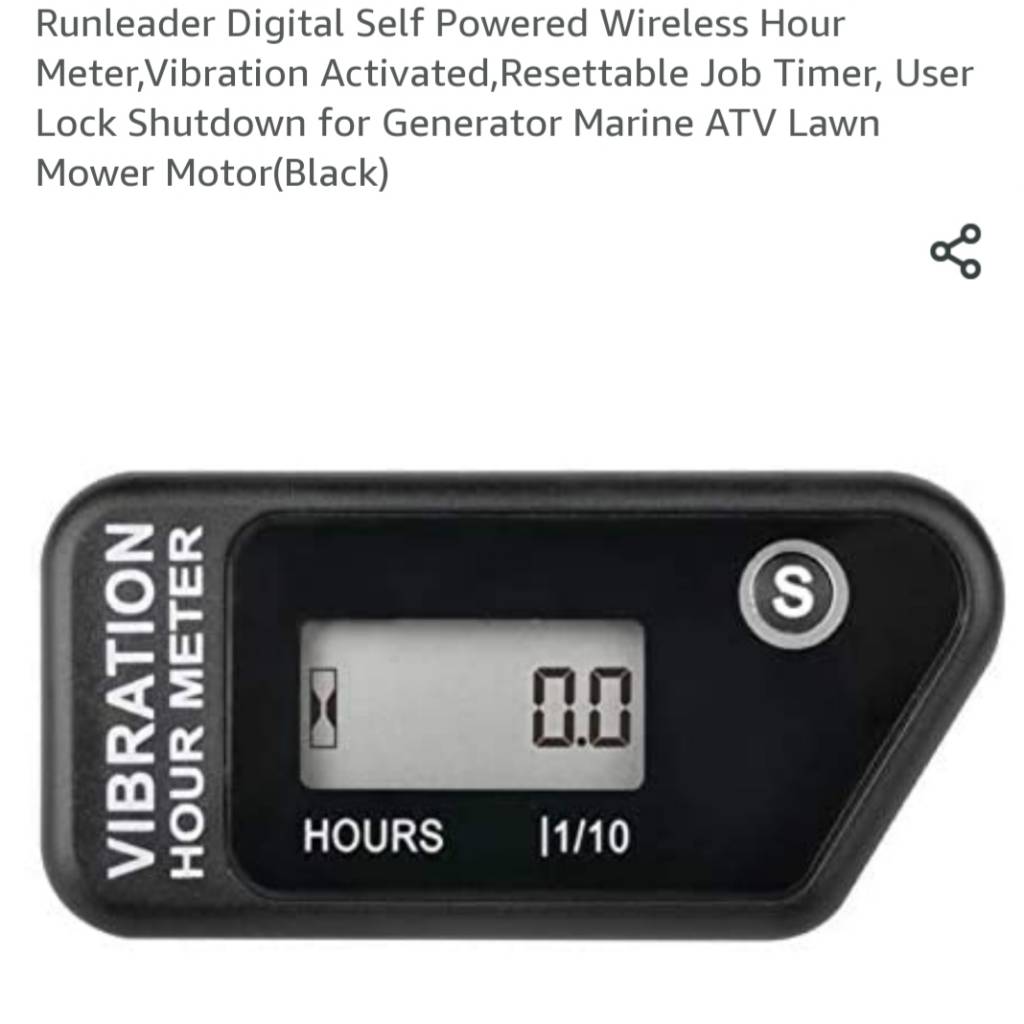

An hour meter makes it easy to track run time for oil and filter media changes. Battery operated and has a peel and stick backing. Nothing you have to mess with - completely automatic.

An hour meter makes it easy to track run time for oil and filter media changes. Battery operated and has a peel and stick backing. Nothing you have to mess with - completely automatic.

Upvote 0