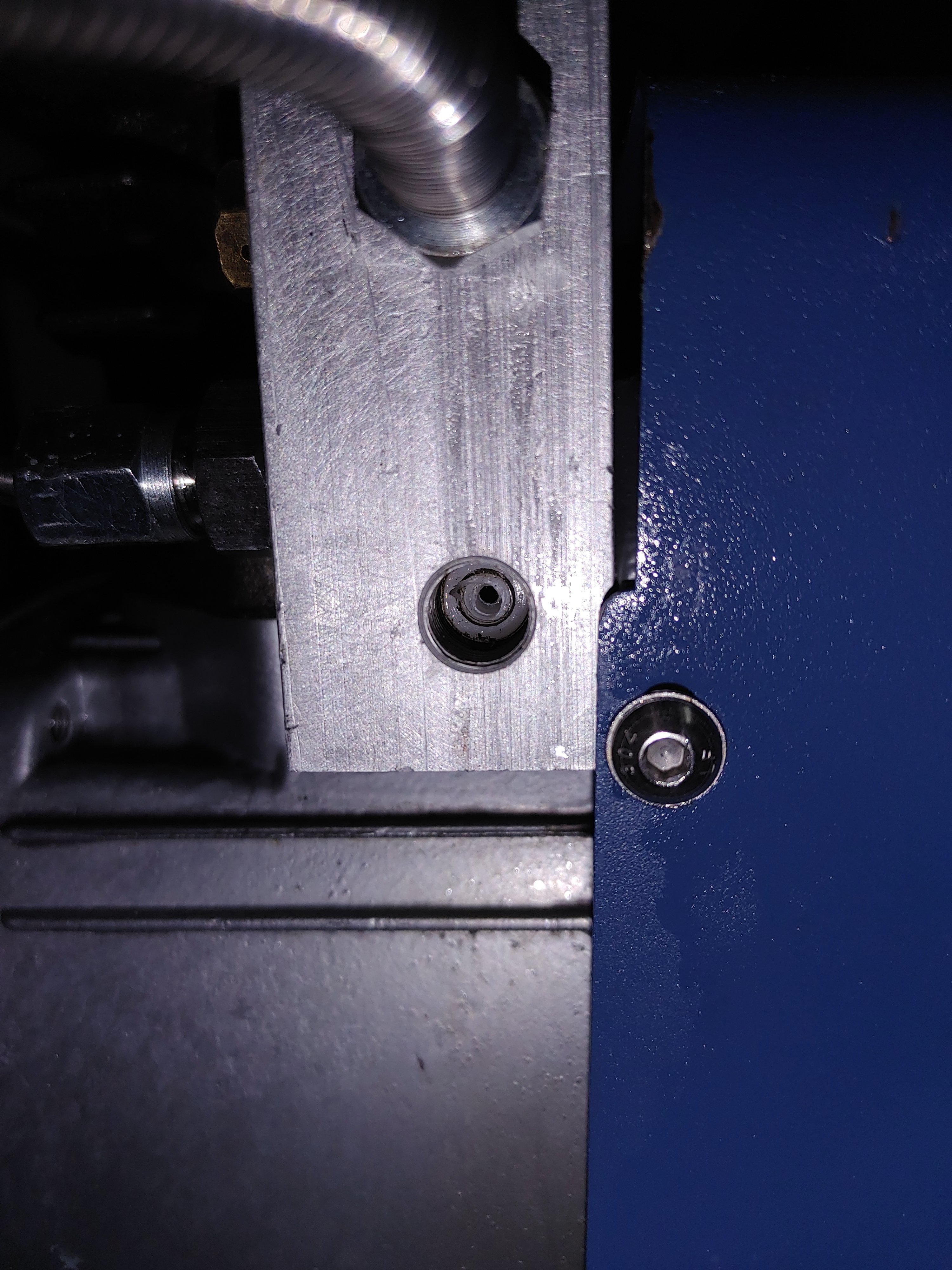

Hey guys could use some help. Not sure what this valve is but everytime I turn off the compressor it sounds like its leaking and its right under the pressure valve. I attempted to take it out and replace it but made it worse. Is there a trick to getting this little plastic gasket out. I was told to use a wood screw but isn't working.

Whats the trick

Whats the trick