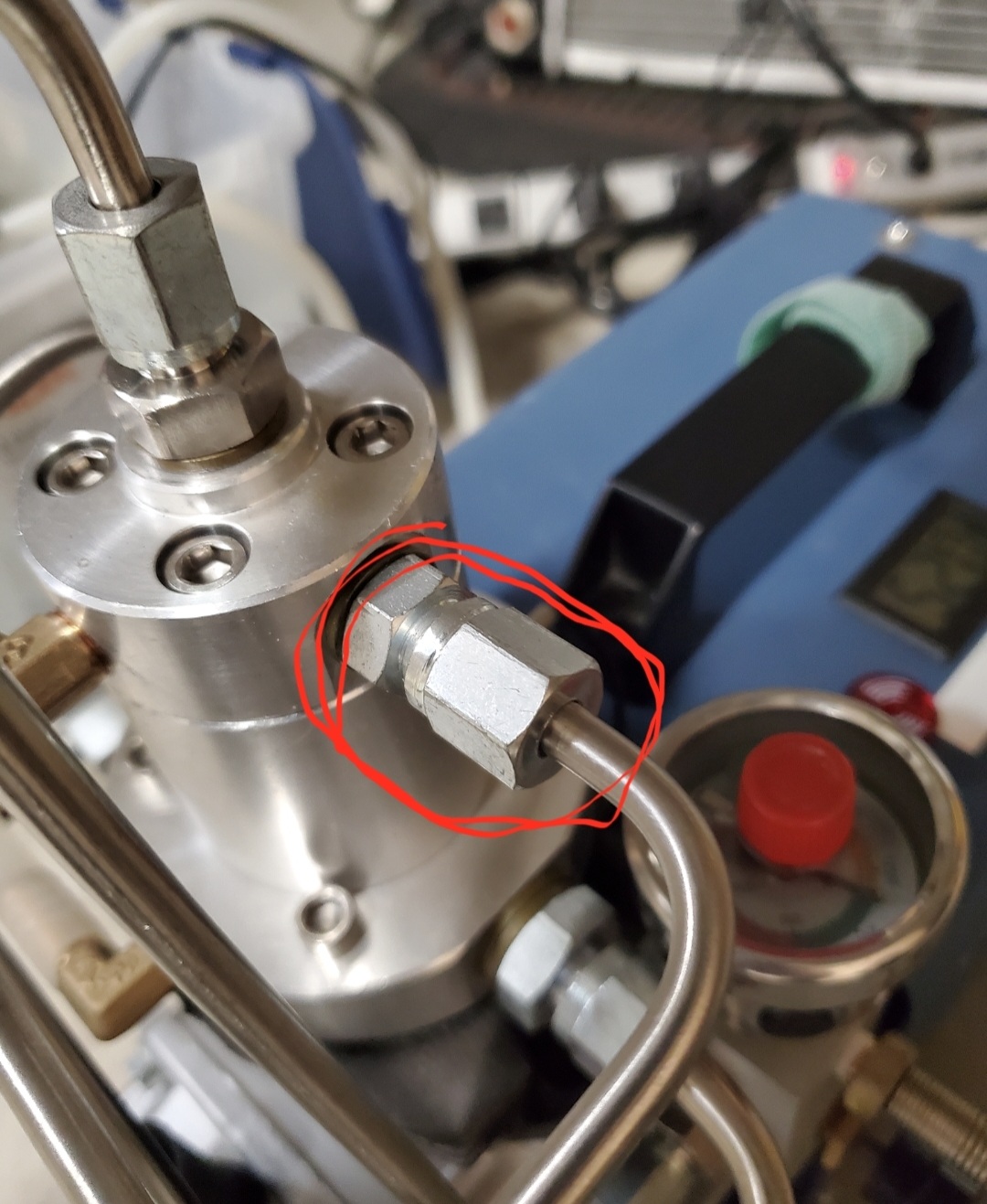

My Yong Heng compressor has ~9 hours runtime and it has developed an air leak. When it was new, I recall getting a max fill of ~4300psi into SCBA 45min tank. Lately it has been around 4000psi before the auto-shut off triggers. Today, I felt air blowing from this fitting (circled in red), I tried tightening it and it still leaks. I believe it is leaking from where the pipe goes into the coupling.

1. Has anyone else had this issue?

2. Can it be fixed by disassembly/reassembly and teflon tape or are new parts required?

Thanks in advance!

1. Has anyone else had this issue?

2. Can it be fixed by disassembly/reassembly and teflon tape or are new parts required?

Thanks in advance!

Last edited: