You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

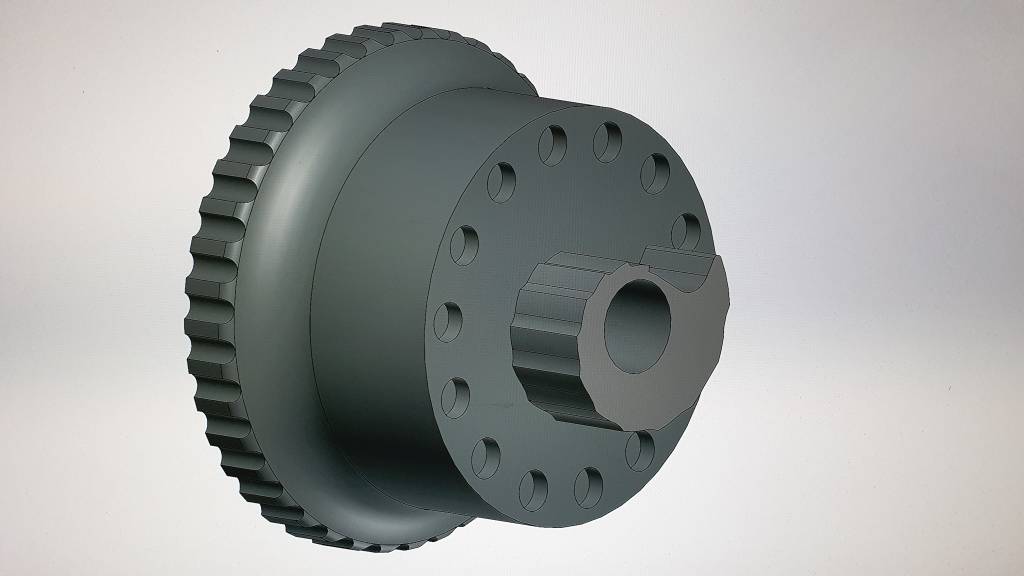

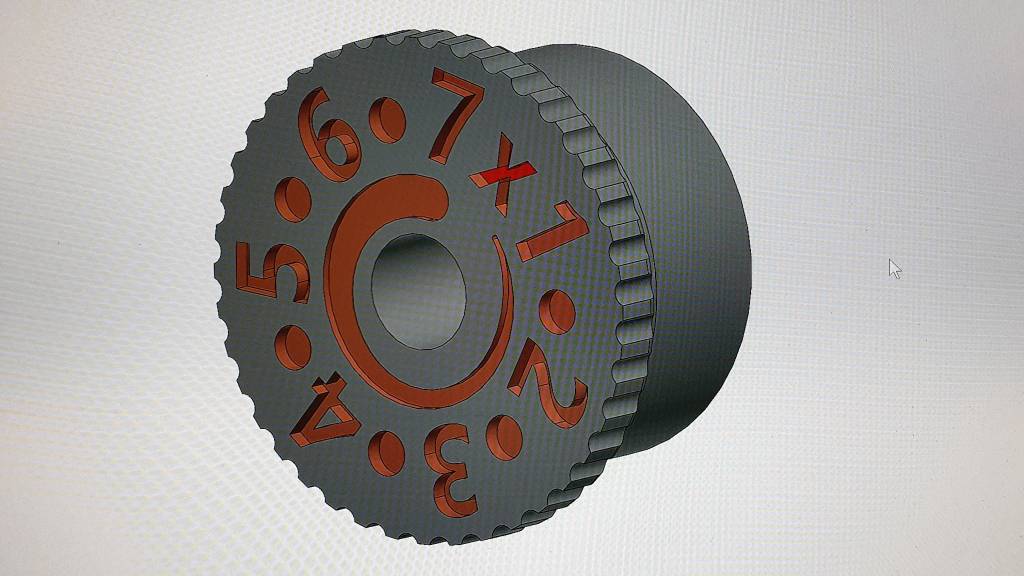

Who’s interested in a 19 step power wheel for the Crown

- Thread starter Mrshosted

- Start date

what is the price going 2 be ?

I'm sorry, I haven't got that far into the build to have clear answer for you. If I build them similar to the Impact model with the black 65 rockwell harden steel, they will be very close to the Impact cost, maybe a dollar or two more just because of the small run. Truthfully, I was only going to build a enough for the guy's here on AGN. But, I was hoping to up my game with better printing on the face and maybe adding other colors. But that may drive the price up. I do my very best to build the highest quality part at a reasonable price. This is very hard in this crazy world. If I had a small shred of hope aluminum or 3d printing would last the test of time, that would ease the pain. But neither will last. As many of you know we worry about the cam profile dimpling under the pressure of the set screw and causing poor performance and maybe counter intuitive of why we would want a finer wheel. For example: if you had been shooting in practice for EBR on setting 14 for an extended amount of time at 4200 feet elevation. Now you if find yourself down the road at EBR in Arizona at a much lower elevation and your gun is shooting 20 fps faster and grouping like dog doodo. With the harden steel wheel it would allow you to just turn your power wheel down 2 clicks and be back to your 4200 foot tune. But if there was a dimple on setting 14, who knows if you could find a new sweet spot. Setting 13 would add hammer and increase the speed. Not lower speed as needed and only confusing you. Why? Because your set screw would be coming out of the dimple of 14 riding and on the ridge of the dimple of setting 14 when on setting 13 with such small amounts movement the points on the cam almost touch. This is why the cam need's to be hardened material. But there's trade off, the hardened material is difficult to engrave, and this type of engraving raise the price. So lies the question, added price for looks or not. I chose not to add to the price on my Impact models. I am working on finding solutions to improving the lettering. But today we focus on performance. Mont

Upvote 0

Please keep us updated, I'm down for 2 now. As far as look goes it's not a huge deal, a little whiteout would do the trick but I haven't wanted that bad enough to go get some whiteout or paint.

Thanks

Thanks

Upvote 0

Hey.

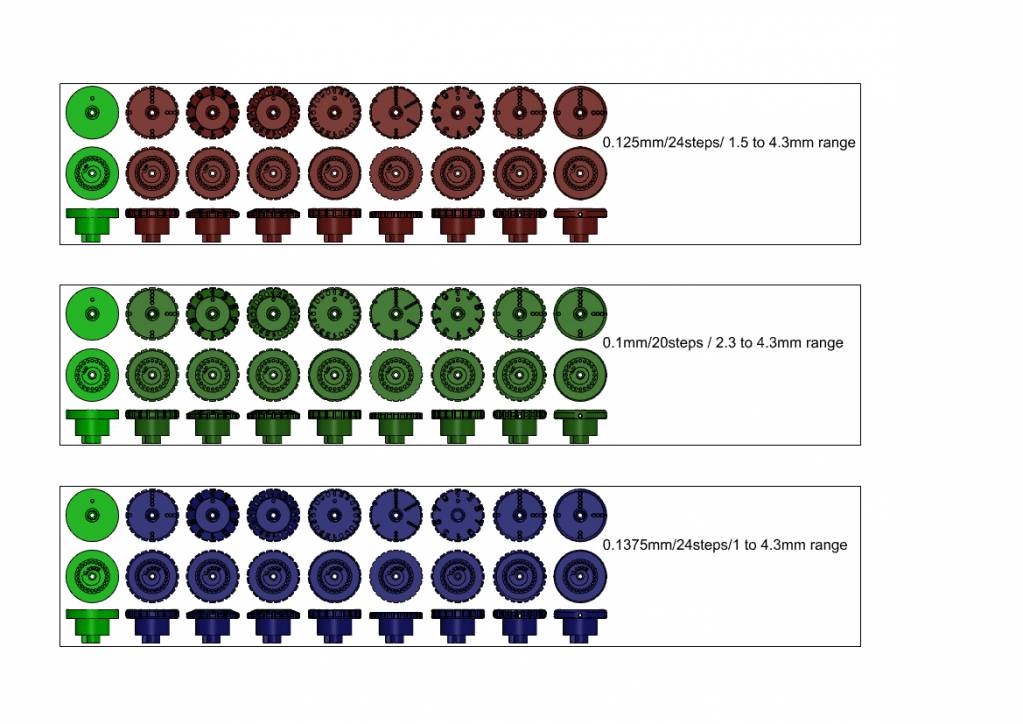

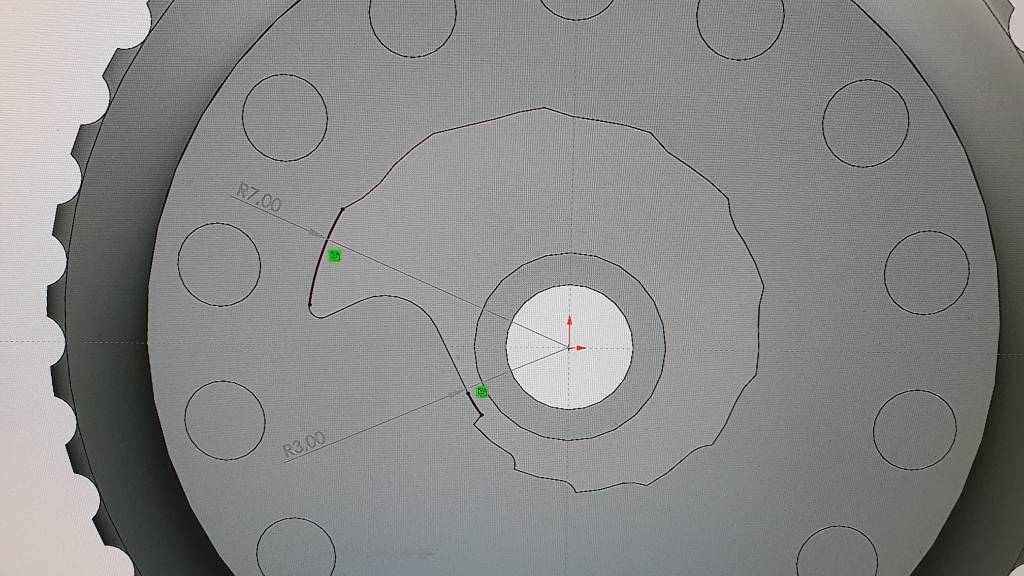

I have designed some power wheels for the Crown some weeks ago. I have tested a few models with different ranges and steps.

Just to help you on your way:

you can't make more than 24 steps. When you do, both bearing balls will slip and hessitate (sorry for the bad english) . A solution could be to use one bearing ball. But I think that this wheel needs two of them to keep it in place.

I have made the outside bigger because you can hardly use it correctly when it's too smal. The height of the base is 8mm. This to give it a few mm clearance from the stock.

Been using it now for a few weeks. The biggest advantage is that you can easaly tune your gun when you are using different ammo. Now you don't need to get that gun out of the stock to finetune it anymore.

I make them on a resinprinter. This material seems to hold up fine. I have shot some 1000 rounds on 140 bar with a .25 and .30 barrel. This material works great for me because I can print a dozen at a time within an hour for just a few bucks. You cannot print them with an fdm printer. You will probably make them from aluminium?

The range on these wheels is smaller. I mean, who uses their lowest settings... I have also designed a 20 step 0.1mm wheel. That relates best to the original finetune. One step on the wheel is the same as 1/6th of a turn with a imbuskey in the fine adjuster.

I have also made a few wheels for the Wildcat mk3 a few days back. They will also fit on the maveric.

I have designed some power wheels for the Crown some weeks ago. I have tested a few models with different ranges and steps.

Just to help you on your way:

you can't make more than 24 steps. When you do, both bearing balls will slip and hessitate (sorry for the bad english) . A solution could be to use one bearing ball. But I think that this wheel needs two of them to keep it in place.

I have made the outside bigger because you can hardly use it correctly when it's too smal. The height of the base is 8mm. This to give it a few mm clearance from the stock.

Been using it now for a few weeks. The biggest advantage is that you can easaly tune your gun when you are using different ammo. Now you don't need to get that gun out of the stock to finetune it anymore.

I make them on a resinprinter. This material seems to hold up fine. I have shot some 1000 rounds on 140 bar with a .25 and .30 barrel. This material works great for me because I can print a dozen at a time within an hour for just a few bucks. You cannot print them with an fdm printer. You will probably make them from aluminium?

The range on these wheels is smaller. I mean, who uses their lowest settings... I have also designed a 20 step 0.1mm wheel. That relates best to the original finetune. One step on the wheel is the same as 1/6th of a turn with a imbuskey in the fine adjuster.

I have also made a few wheels for the Wildcat mk3 a few days back. They will also fit on the maveric.

Upvote 0

I have one 3d printed. Now there's no way a 3d printed part will work for any amount of time. But it will allow for a fit check. with some miner testing. I'm hopping to meet up with a Crown and a Dreamline this weekend for a fitting. If all goes well hopefully I'll have time to machine a prototype out of stainless steel next week.

Thank you for all the support, Mont

Maybe stupid question but why would a 3D printed part ( provided correct hard resin) not work for any amount of time ?

”3D printed parts are very strong, especially when using specialized filament like PEEK or Polycarbonate, which is used for bullet-proof glass and riot shields. Infill density, wall thickness and print orientation can be adjusted to increase strength.”

Upvote 0

Even the factory anodized ones don’t last long. Every time you cock the gun it puts quite a bit of force on that small set screw and it just stars to dig right into the wheel.

Upvote 0

Exactly…as you say. Even factory anodized (aluminium) parts do not last long . The material is not the problem but the set crew should have a ( bigger) rounded head. Problem solved ! Nothing to do with the 3D print or its material compared with aluminium normally used.

Upvote 0

Same kind of issue from an other tread copy pasted below. Meanwhile FX has changed from red to blue circled make. I have one of the first made WCmk3 with the “aluminium eating grub screw” and found this issue only recently. With a round head bolt like on the blue circle picture neither aluminium nor resin from 3D printed parts will get damaged. I will ask for a free replacement of the bolt as well as my damaged wheel as I believe this is a product/design failure. That can happen though , no hard feelings here but I hope FX ( and its dealers) will solve this well with the gun users affected. I will report about follow up.

“After a 2 month wait fox has sent me the wrong screw(old style) for my power adjuster. I’ve got the old style in my gun circled in red. I told them I needed the new style circled in blue, since the old style eats into the power wheel. “

“After a 2 month wait fox has sent me the wrong screw(old style) for my power adjuster. I’ve got the old style in my gun circled in red. I told them I needed the new style circled in blue, since the old style eats into the power wheel. “

Upvote 0

Sounds like OP is going stainless route instead of harden steel like the impact route. Even though I don’t live somewhere with high humidity I would still think stainless is easier to worth with and last about as long or longer than resin/aluminum. I’m a fan of OP’s impact wheel and hoping the stainless crown wheels will come out soon because I need 2!

while wildcat hammer screw is easy to fix with a cap or nut of some kind the crown and impact’s hammer screw is too small to have a cap on. A harder material power wheel is the way to go!

while wildcat hammer screw is easy to fix with a cap or nut of some kind the crown and impact’s hammer screw is too small to have a cap on. A harder material power wheel is the way to go!

Upvote 0

I am interested in getting 2 of these power wheels. How can I buy 2 of them.

Appreciated for any help.

Appreciated for any help.

Upvote 0

Hi All.

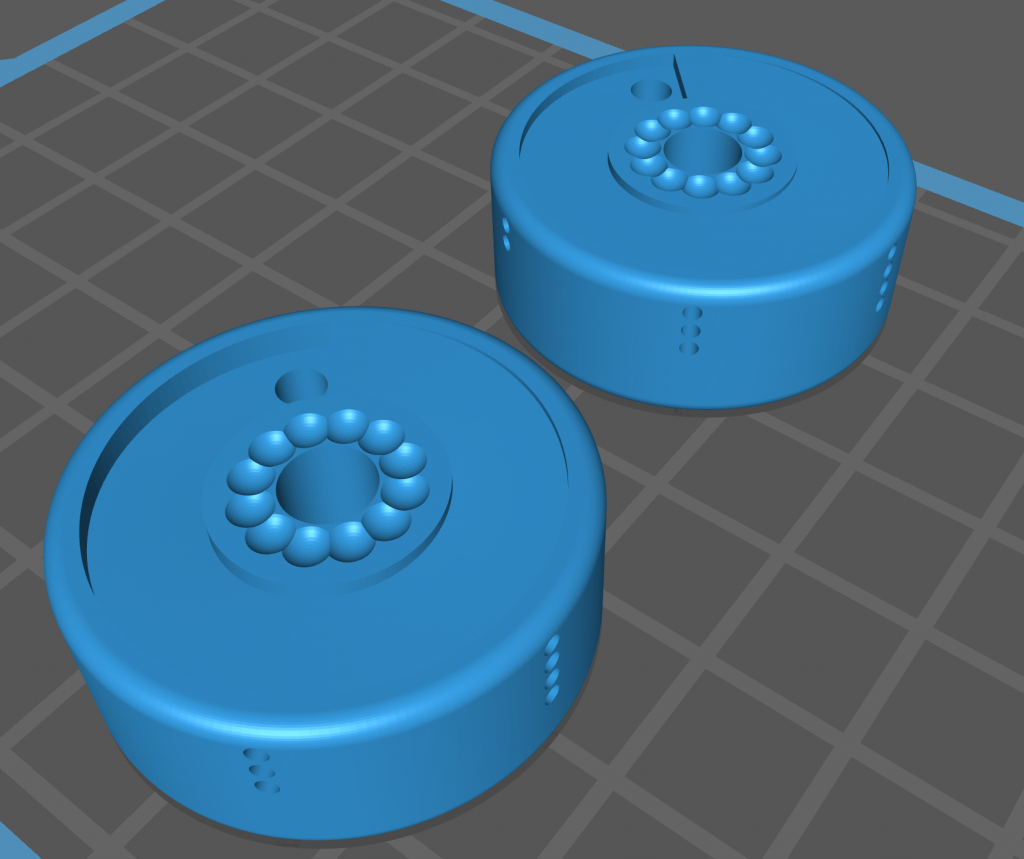

To the once that questions the 3d printed version. I used my own 3d Printed power wheel for 10 month now.

Just did a overhaul in the weekend and looked at my power wheel - still no problems.

I printed the power wheel in Petg fillament. I did as you see on the images make the positions on the power wheel in steps.

This version gave me 13 individual power steps.

Claus

To the once that questions the 3d printed version. I used my own 3d Printed power wheel for 10 month now.

Just did a overhaul in the weekend and looked at my power wheel - still no problems.

I printed the power wheel in Petg fillament. I did as you see on the images make the positions on the power wheel in steps.

This version gave me 13 individual power steps.

Claus

Upvote 0

Does the Dreamline use a different wheel or will the Crown or an Impact wheel fit the Dreamline? I have a couple DreamTac’s that I would like to get these for.

Upvote 0

OK so here is my first review of a custom Air gun part so please bear with me as I stumble through this. First off let me say that I by no means a pro air gunner. I just got started in May of 21, and have tuned 2 rifles. An avenger, and a Crown MKII both in.22. Second dealing with Mont through this process has been a treat. Unknown to me I had a regulator gauge that was 9.5 bar off, on the low side, and could not figure out why I was having such poor performance. I must have messaged Mont on here 50 times trying to figure out my issues. He never hesitated to give me advice. I ordered a Huma digital gauge, and 2 new gauges. Once I discovered my issues, and followed Monts advice, tuning my crown was a snap. The only mod to my gun at this point is a Huma dual transfer port. Now with the pre-emptive out of the way below is my review.

I am shooting NSA 23 gr, .217 slugs. My target speed was 950-960. I set the reg at 140 bar, the power wheel to 3, the grub screw I followed Steves advice from AEAC and adjusted it to factory. Then following Monts advice I sot a 6 shot string on setting 3. Moving the wheel up 1 click, I then shot 4 shots over the chrono watching my speed. And continued this till I saw my speed drop. This happened on setting 12, so I gave the gun 5 more bar of air, backed the wheel down a few steps and repeated the process. as I started coming back up the wheel I was getting really close to my target speed. I got to 955 at setting 17, by 19 I was pushing 960-965, the gun was still shooting up and down the range as the hammer spring had not been adjusted. When adjusting the grub screw I moved it ever so slightly, barely noticeable movement. I started shooting 9 shot groups at this point. Just trying to get that SD/ES as perfect as I could. Here is 1 of the groups I sent to Mont trying to figure out why my 4, and 9 shots were 17 fps slower. He explained to me that the FX pocket radars sometimes can read erratic, and to continue tuning.

So with all of that said you folks are probably wondering what I thought of Monts wheel. Fitment was spot on. I did use a nylon washer under the screw to give it a smoother rotation when tight. Other than that it was spot on. I do have the "Gen 1" wheel that doesn't have the raised portion at the top to grasp when making changes. This does make it a bit tougher to make the adjustments with the GRS Stock model Crown, but Mont has already addressed this. I don't know how to describe the ease at which I was able to tune my gun after finding the faulty gauge issue using this wheel. The smooth, flowing curve this wheel gives you over the "choppy" factory wheel is amazing. As you go up, or down on the wheel and watch a graph with your chrono the linear motion of each shot is so smooth and clean. With the factory FX wheel I noticed the graph was not a smooth linear motion, but made large peaks and valleys between each wheel position. Due to the fantastic weather in Northern West Virginia I have not had the ability to go out and bench shoot my gun, and zero it. I know that just changing the power wheel will have no bearing on the accuracy of my gun, however having more positions on the wheel and the smooth linear motion it creates in the power curve, if I need to back down my speed so the slugs are happier it will be a breeze. I will add some photos to this post once I get home of the power wheel in place and the ramp on the power wheel to show any signs of wear, I am also going to put the factory knob back on, and retune my gun with it since I have proper reading gauges for an honest apples to apples comparison. I have no doubt in my mind that Monts wheel will still be the blue ribbon winner. Mont is working up a price point for these, so I do not know the cost, but let me tell you this is a worthy investment for your rifle. I honestly will say that it is a 100% improvement over factory. I hope my ramblings make sense to you fine folks here. Feel free to message me any questions/comments you might have. Also a special shout out to Mont for sending me this wheel to try out, and test for him. Cheers.

Here are the pics, internet was out at the cabin.

Upvote 0