You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

N/A Who's Casting or Wants to Learn?

- Thread starter RM.510bigbore

- Start date

The powder coat doesn't interfere at all. It usually pops off in one piece and floats to the top of the melt. I skim it off as it does.I'm almost there. I don't have the equipment but do have questions.

Does the powder coat prevent recycling the metal repeatedly? Or is it a slag thats removed cleanly during the melt?

Does anyone have a link to a casting equipment build, or better yet, does anyone have spare equipment? A melter or molds?

D

Deleted member 54733

Guest

I see a lot of people worried about fumes and buying equipment to vent it out. Waste of time and money IMO, and let me tell you why. I have been casting lead since the mid 50's, that's the 1950's. Nobody knew, heard or cared much about even ventilating fumes let alone cluttering up the shop with equipment to do it. Melting, casting, working with lead, even welding in the Boston shipyard for years and shops for more years, and I'm still doing it. You do what you want, but it's just a waste of time and money the way I see it. BTW, I'll be 78 in July and I'm still healthy and doing what I want.

Upvote 0

@Mitch333 If I were you I probably wouldn't be worried either. As far as I can tell taking more than necessary precautions hurts little to nothing. Conversely, being careless and not heading the warnings of others including other hand loaders, occupational safety standards, or healthcare professionals is negligent, foolish, and potentially costly. I'd rather spend and lose the time and money taking more precautions than necessary as opposed to not spending the time and money and end up adversely affecting my quality of life.

Upvote 0

D

Deleted member 54733

Guest

Ya, that's you. Spend your money how you want, but quit following me around and posting your snide poop. It's getting old.

Upvote 0

@Mitch333 Follow you around? Yea ok. I’ve been active in this thread which is obvious. What I can do is block you so I don’t see what you post, you won’t see what I post, and you won’t have to worry about being offended by my opinion. Nothing in my last post was intended to be snide. If I had your experience I don’t think I would be concerned, but I don’t.

Upvote 0

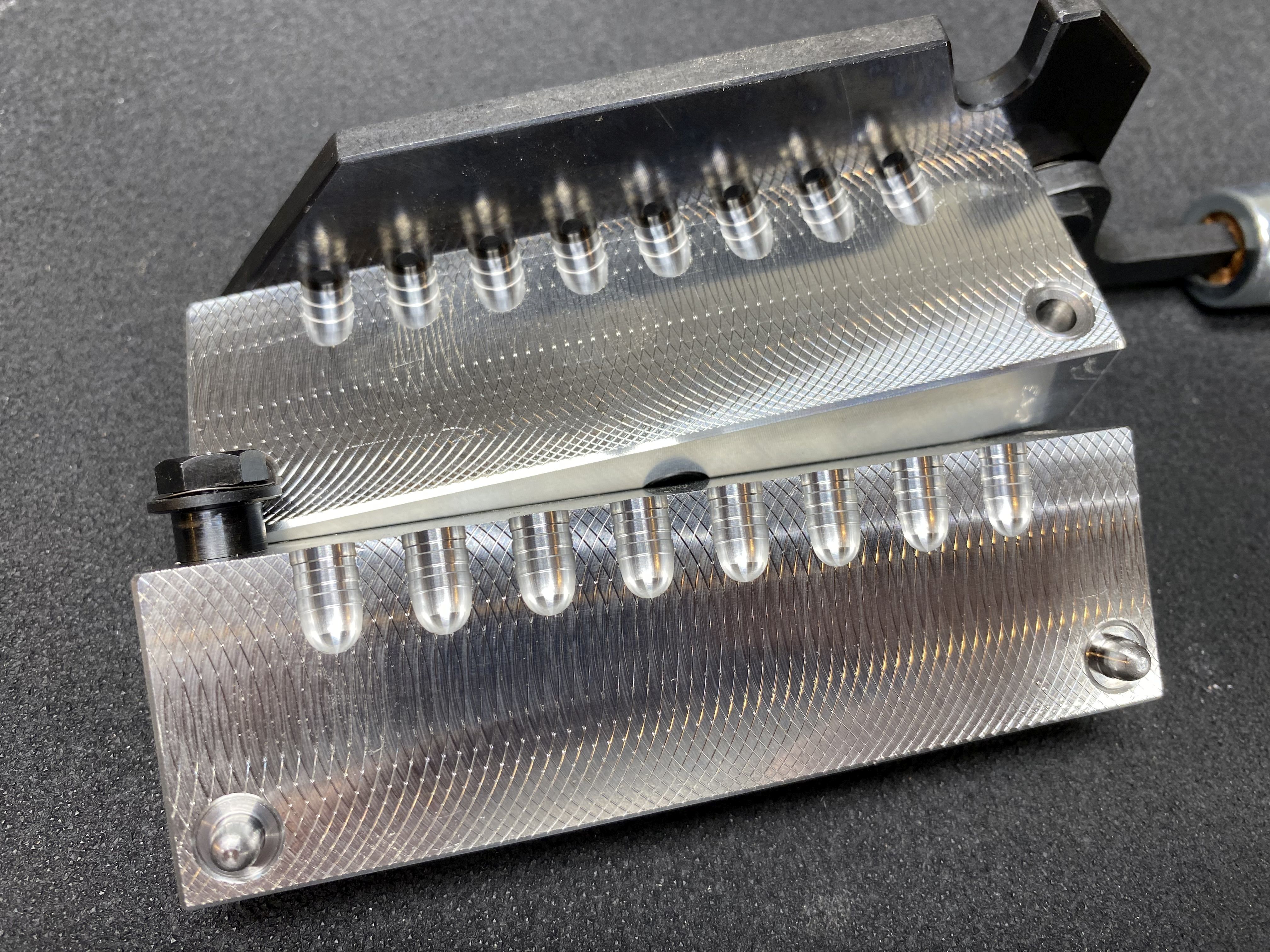

New .25 cal MP Mold arrived today. Nice tool, quick shipping from overseas. I should drop around a 50gr bullet.

Upvote 0

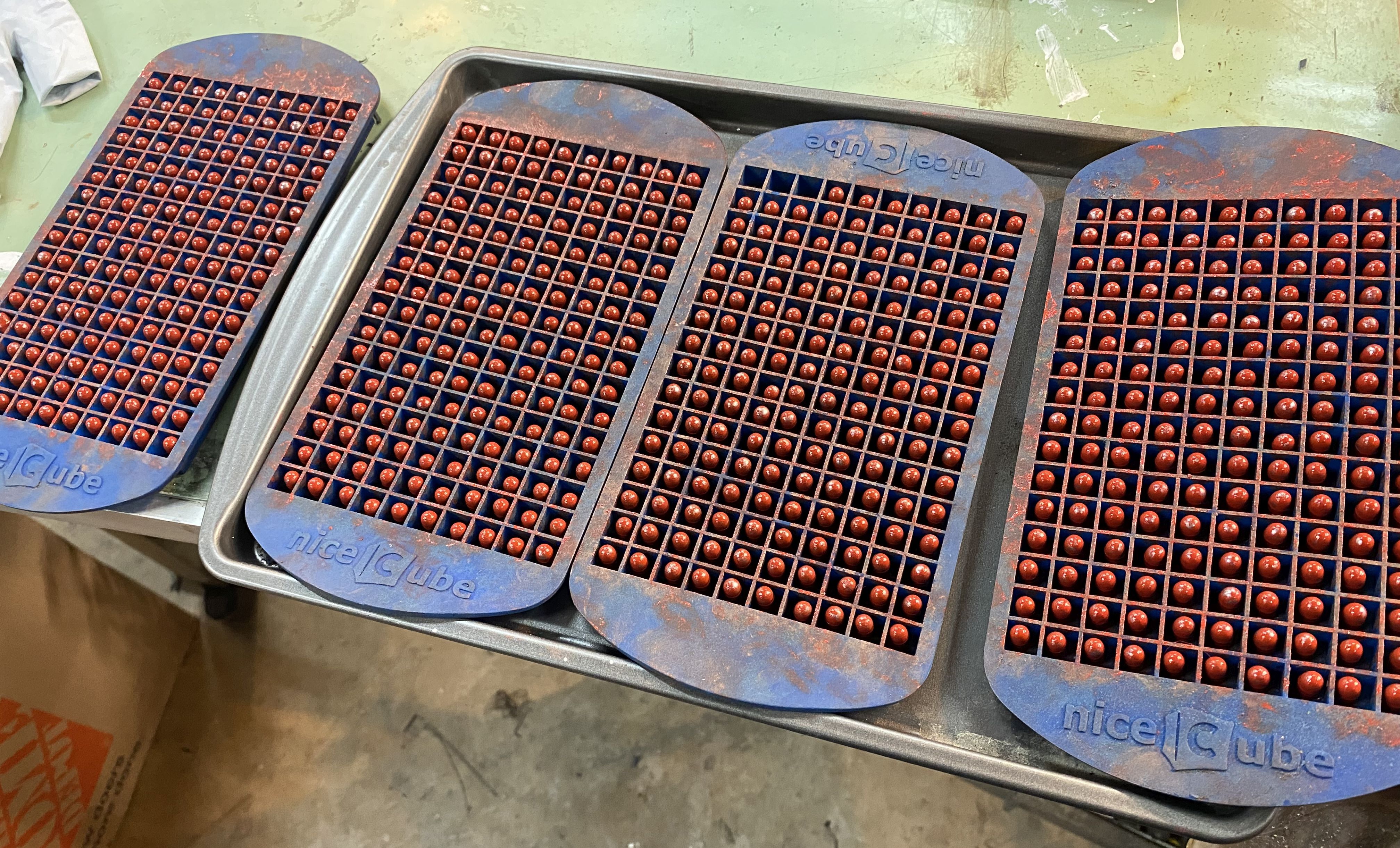

My last secession of casting and powder coating at least 100 lbs. 650 grain Spire Point Boat Tail. .5 B.C .510 Accurate Molds. And NOE 460 grain .510 slugs my go to.... I reclaimed all lead for free  I have much more time than money

I have much more time than money

. I need to buy the new Lee App bushing size die.....My bore slugs .510.5.....I wanna size to .511 My molds cast at .512 and .513.....

. I need to buy the new Lee App bushing size die.....My bore slugs .510.5.....I wanna size to .511 My molds cast at .512 and .513.....

Upvote 0

Please let us know what gun you'll be shooting these out of and the distance. I noticed that this might be a new item, but untested.New .25 cal MP Mold arrived today. Nice tool, quick shipping from overseas. I should drop around a 50gr bullet.

View attachment 431475

Yes, I think it is a new design for MP. I will be shooting them out of these beauties.

Those are some very good looking bullets my friend, I need to cast some more 458 bullets for my Quackenbush Big Bore Bob tuned 458 it has a 36" barrel.My last secession of casting and powder coating at least 100 lbs. 650 grain Spire Point Boat Tail. .5 B.C .510 Accurate Molds. And NOE 460 grain .510 slugs my go to.... I reclaimed all lead for freeI have much more time than money

. I need to buy the new Lee App bushing size die.....My bore slugs .510.5.....I wanna size to .511 My molds cast at .512 and .513.....

View attachment 431567

View attachment 431568

View attachment 431569

To water separate place the hose end into the bottom and turn it on full blast and skim the floating off.. The rubber mulch isn't buoyant enough by itself, that is why you need the forces of the water to lift it up..

Upvote 0

Almost 640 rounds off the new MP mold.

Great progress. Are they sized .251 or .249, or as cast? Can you compare them to the 47 grain variety?

6,35 mm air pellet - 8 cavity AL mold - MP-molds

Best moulds for casting lead bullets. Hollow point, hollow base or solid bullets. Molds are Brass or aluminum.

www.mp-molds.com

www.mp-molds.com Upvote 0

Right now they are as cast. I will size them to match the rifles. Yes will compare to the other 25 cam MP mold which I also have.

Upvote 0

Here are some 302gr solids and cup nose bullets I cast from the NOE 460-315-RF 2 cavity mold sizing to 458 to shoot in my Quackenbush Outlaw 458 tuned by Big Bore Bob Dean.

I swage but I've been holding on to my waste lead. Most in the form of the thin extrusion bleed off. I was planning on waiting until I have enough to justify the shipping cost, and offer it to someone on here for free, just the cost of shipping. I'm wondering if it's worth it though. Since it has a high surface area to volume ratio and is exposed to air, would there be more slag than is worth it if melted? Should I just toss it?

Upvote 0