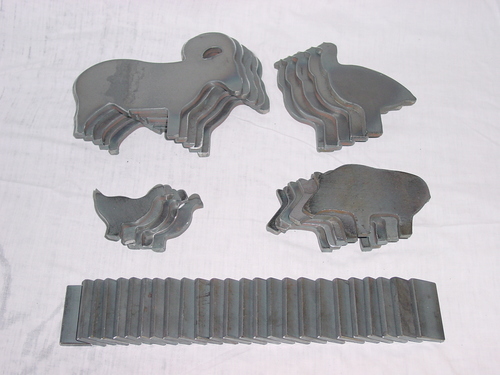

Hi, I was wondering if anyone could tell me what machine is used to cut small shapes out of hard 1/4 in steel. Like the pics below. Thanks -Nate

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What Machine will Cut 1/4 Steel Shapes?

- Thread starter kaylaindy

- Start date

If you want to do this yourself (and not bust the bank) you could do it with a hand held plasma cutter, you will likely be dealing with a bit of clean up. Plus if you are wanting air gun targets you don't have to use something like AR500, mild steel will do just fine, if it will take a rimfire it will take about every pellet you can toss at it.

Upvote 0

There is probably a small shop in your area that does laser cutting. Not sure what file type they require, but send them your design and they will cut parts from the material of your choice. Nice thing about the process is no tooling required so no tooling cost.

https://www.lasercuttinginc.com

https://www.lasercuttinginc.com

Upvote 0

Thanks guys! I guess I would need mild steel. Thanks for that tip. I’ll look into laser cutting and some local cutting shops. I want to make some Airgun targets and shooting gallery type stuff. I had no idea where to start. Thanks again -Nate

Upvote 0

Laser/waterjet/plasma cutters tend to like a 2D .dxf file. They can import it into their software for nesting the components. Try to minimize your selection of material thicknesses. It will save on set-up charges. Laser cutting can produce a sharp edge on corners that's hard on the fingers so a small radius helps prevent this.

Upvote 0

Good question! I just started learning the other day and am still totally lost. The plasma cutter suggestion for your requirements seems interesting. I’ve been looking at a mill for making airgun parts. Between a mill and mini lathe I think I could crank out the stuff I’d need outside of barrels which would need a much larger and high quality lathe I imagine.

My father uses a laser to make model rail road stuff for a living. Ships to hobby stores world wide. Just bought a laser one day and started doing it lol.

My father uses a laser to make model rail road stuff for a living. Ships to hobby stores world wide. Just bought a laser one day and started doing it lol.

Upvote 0

Darn, The HP series for about $4k to $7k only cuts 1mm thickness. You need an FC series to cut 1/4 steel. They are $69k.

https://www.bosslaser.com/metal-laser-cutters/

https://www.bosslaser.com/metal-laser-cutters/

Upvote 0

Why not just get a welder to cut them with a cutting torch. It can be done with a professional look by someone that's handy with the torch. This would probably be your easiest to find and cheapest option.

Jking

Jking

Upvote 0

It would depend on how many you would want to make. Doing it by hand one at a time would get old real fast.

it would seem to me if the size is approximately what is showing the water jet would be the way to go. Laser more for smaller stuff ?

it would seem to me if the size is approximately what is showing the water jet would be the way to go. Laser more for smaller stuff ?

Upvote 0

As an ex custom shop owner/operator,

I'd have to say: 1: Water Jet. or 2: Plasma Cutter - for quick efficient production runs.

Laser would be nice, but, I don't know of any shops w/ them or that would do small runs - and I'm in NY.

Using o/a torches is definitely another viable option, but, I'd say more for limited numbers..

Where water-jets produce the cleanest cuts..

Plasma will still require more clean-up from melting the metal

And Torch will create even more melted metal - needing to be cut off / ground / shaped / sanded..

Personally - I was more of a limited run custom shop, so, I'd use my plasma torch,

then manually use an angle grinder or Foredom rotary tool to grind/shape/sand

MILD Steel is pretty decent to work with..

Hot Rolled is the most 'user friendly'

Cold Rolled - is stronger and a bit more of a pain to work with.

AR [Abrasion Resistant] is super strong, and brutal to work with.

By *work with* - I mean using hand tools if/when needed

[due to the strength of the metals used]

1/4" isn't very thick - Until' it comes down to cutting / shaping / welding it.

Most 'consumer' tools aren't designed to work with metals that thick..

You could get away with using a drill, few bits, and a scroll-saw,

but by the time you get done with them, you'll have to shave again. lol

I still have a mini plasma cutter [250 amp TIG welder w/ plasma torch add-on]

It was okay for like 1/8" but would be a pain when doing upwards of 1/4"

Also, they require a pretty good compressor w/ high/steady CFM airflow

Sam -

I'd have to say: 1: Water Jet. or 2: Plasma Cutter - for quick efficient production runs.

Laser would be nice, but, I don't know of any shops w/ them or that would do small runs - and I'm in NY.

Using o/a torches is definitely another viable option, but, I'd say more for limited numbers..

Where water-jets produce the cleanest cuts..

Plasma will still require more clean-up from melting the metal

And Torch will create even more melted metal - needing to be cut off / ground / shaped / sanded..

Personally - I was more of a limited run custom shop, so, I'd use my plasma torch,

then manually use an angle grinder or Foredom rotary tool to grind/shape/sand

MILD Steel is pretty decent to work with..

Hot Rolled is the most 'user friendly'

Cold Rolled - is stronger and a bit more of a pain to work with.

AR [Abrasion Resistant] is super strong, and brutal to work with.

By *work with* - I mean using hand tools if/when needed

[due to the strength of the metals used]

1/4" isn't very thick - Until' it comes down to cutting / shaping / welding it.

Most 'consumer' tools aren't designed to work with metals that thick..

You could get away with using a drill, few bits, and a scroll-saw,

but by the time you get done with them, you'll have to shave again. lol

I still have a mini plasma cutter [250 amp TIG welder w/ plasma torch add-on]

It was okay for like 1/8" but would be a pain when doing upwards of 1/4"

Also, they require a pretty good compressor w/ high/steady CFM airflow

Sam -

Upvote 0

Water Jet gets my vote. I have a guy here locally with a giant waterjet in his shop and it's amazing. I've had him cut me some parts out of 1/4" mild plate steel and they had an excellent edge finish. I just take him a drawing or template and he does the rest.

Upvote 0

It depends if you want to do it yourself or outsource the work to someone else. The cheapest way in order of outsourcing would be cnc plasma, waterjet then laser.

If you like to make things, then oxy/acetylene, hand held plasma or cnc plasma table in order of cheapest to most expensive. You can make amazing stuff with a torch by hand, it depends on your skill level.

With a cnc plasma you can get amazing edge quality with little clean up, but the edge will always have a slight bevel to it.

Example: here or pics of some 3/16 mild steel straight off a cnc plasma table. A quick scrape with a wide chisel by hand usually knocks off the slag on the back side. Personally 1/4" and 1/2 cuts even better.

If you like to make things, then oxy/acetylene, hand held plasma or cnc plasma table in order of cheapest to most expensive. You can make amazing stuff with a torch by hand, it depends on your skill level.

With a cnc plasma you can get amazing edge quality with little clean up, but the edge will always have a slight bevel to it.

Example: here or pics of some 3/16 mild steel straight off a cnc plasma table. A quick scrape with a wide chisel by hand usually knocks off the slag on the back side. Personally 1/4" and 1/2 cuts even better.

Upvote 0

Hey guys, I want to produce targets so I'm looking at getting 100's of the same few pieces. Definitively, I can't do anything by hand. Water jet service or a Plasma CNC sounds good. I wonder how cheap I can get a CNC Plasma cutter. It has to be a clean edge. Like this:

Upvote 0

That type of cutting is made for a laser. You get a nice clean edge that doesn't require clean-up after. Google the fabrication shops in your area. Laser cutting is very popular and cost effective. I do machine design and a lot of the fabrication components i design have laser cutting considered into the design. Some places laser cut thicknesses up to 3/4" or 1". I know of at least 4 shops in my area that do custom laser cutting. These guys dont care the size of the job. They will just nest your components with another job using the same material and thickness. Larger the run the better the price though.

Upvote 0

rob_g: Thanks dude! That's just what I needed to know.

I'll be off and running this Monday morning. I'm 20 mins from Portland and Vancouver so I'm sure there will be plenty of shops.

Thanks for all the info guys! -Nate

I'll be off and running this Monday morning. I'm 20 mins from Portland and Vancouver so I'm sure there will be plenty of shops.

Thanks for all the info guys! -Nate

Upvote 0

I’ve used a website: sendcutsend.com For exactly this. I’ve sent them an adobe illustrator file, and about 4 days later I received perfectly cut parts. You can choose nearly any metal you can imagine in a variety of thicknesses. I believe all their work is laser cut. It’s amazing. Cut to a thousandth of an inch precision. Check them out. You need a simple .ai file made? Feel free to hit me up (I’ve been working illustrator for the better part of 25 years). Good luck!

Upvote 0

One more thing - there’s no minimum order for sendcutsend. Order just one piece or 5000! (The more you order, the cheaper it is per piece of course)

Upvote 0