I am getting familiar with my fairly new hw35, and eagerly awaiting my hw97 from AoA. Being retired, I am shooting every day and as this is my first springer, I am learning a great deal from the rifle and the kind folks on this forum. Not being blessed with any semblance of handiness, I tend to learn by trial and error, much too much error. Anyway, I survived my latest crises and learned that I did not, in fact, break two scopes in a row, in the same day. The great shot groups, followed by erratic groupings turned out to be loose stock and ring screws.

Despite having no skill with my hands, I have accumulated a large number of screwdrivers over the years, yet I seem to have none that are a proper fit for the screws on my hw35. Forearm screw, rear trigger guard screw, front trigger guard screw and Rekord trigger screw, I have screw drivers of reasonable width, but not thickness and/or shank length. It is clear I will need to tighten these things regularly, so I need to buy proper screwdrivers.

Can someone please tell me the specific sizes of screwdrivers I need?

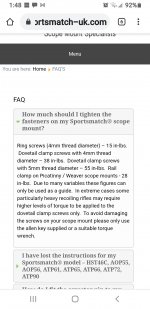

Also, I have read here that I need my Sportsmatch rings to be about 30lbs torque for the bases and 15-18 lbs for the rings. How about the torque for the stock screws?

Any assistance will be greatly appreciated.

Despite having no skill with my hands, I have accumulated a large number of screwdrivers over the years, yet I seem to have none that are a proper fit for the screws on my hw35. Forearm screw, rear trigger guard screw, front trigger guard screw and Rekord trigger screw, I have screw drivers of reasonable width, but not thickness and/or shank length. It is clear I will need to tighten these things regularly, so I need to buy proper screwdrivers.

Can someone please tell me the specific sizes of screwdrivers I need?

Also, I have read here that I need my Sportsmatch rings to be about 30lbs torque for the bases and 15-18 lbs for the rings. How about the torque for the stock screws?

Any assistance will be greatly appreciated.