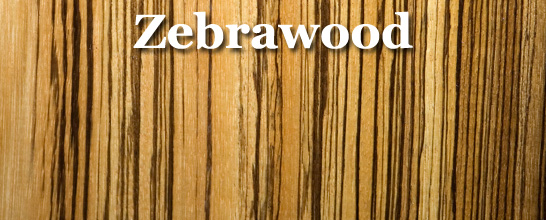

Two year after the possession of my "short", I finally decided to give at this "muscular" bullpup a stock manufactured with a precious essence and as the title of the thread says, surely you understand that the block in question is Zebrano (Zebrawood) , a very particular wood for various reasons: dark brown veins, which in the most valuable tables are perfectly horizontal and ... the characteristic and unique smell that distinguishes this essence, the smell of horse dung, which is released especially during the processing, causes overheating of the oils contained in the fibers.

The purpose of this custom stock is to replace the original stock, not so much because it is ugly ... indeed, but for the fact that it has some design defects:

- butt pad made with a rubber, too hard among other things, which seems to derive directly from a shoe sole: lipssealed: ..... certainly the most unhappy piece of this weapon; the butt plate thus made is absolutely non-ergonomic and very uncomfortable once it is placed on the shoulder, as it is flat and too small.

- Forend too steep and short

- pistol grip not very ergonomic, even if comfortable

- overall too short stock; missing, at least for my physical structure, about 4 cm.

The purpose of this custom stock is to replace the original stock, not so much because it is ugly ... indeed, but for the fact that it has some design defects:

- butt pad made with a rubber, too hard among other things, which seems to derive directly from a shoe sole: lipssealed: ..... certainly the most unhappy piece of this weapon; the butt plate thus made is absolutely non-ergonomic and very uncomfortable once it is placed on the shoulder, as it is flat and too small.

- Forend too steep and short

- pistol grip not very ergonomic, even if comfortable

- overall too short stock; missing, at least for my physical structure, about 4 cm.