I finally upped my Huma reg pressure in my 22 cal Vet above 170 (to ~173-174 bar). Shot all my Griffin boat tail test ammo last weekend, except for the 40 grainers. They shot real well with my 600mm FX slug liner, but I could only run them around 865fps that day.

So this week, I decided that I would retune it to see how fast I could get them up to. Harmonics have been a major problem to deal with when shooting 30-36+ grain ammo. I saw that everyone and their mother was sleeving their FX liners with carbon fiber, my first attempt wasn't great - but I realized what I would do next time if I choose to try again.

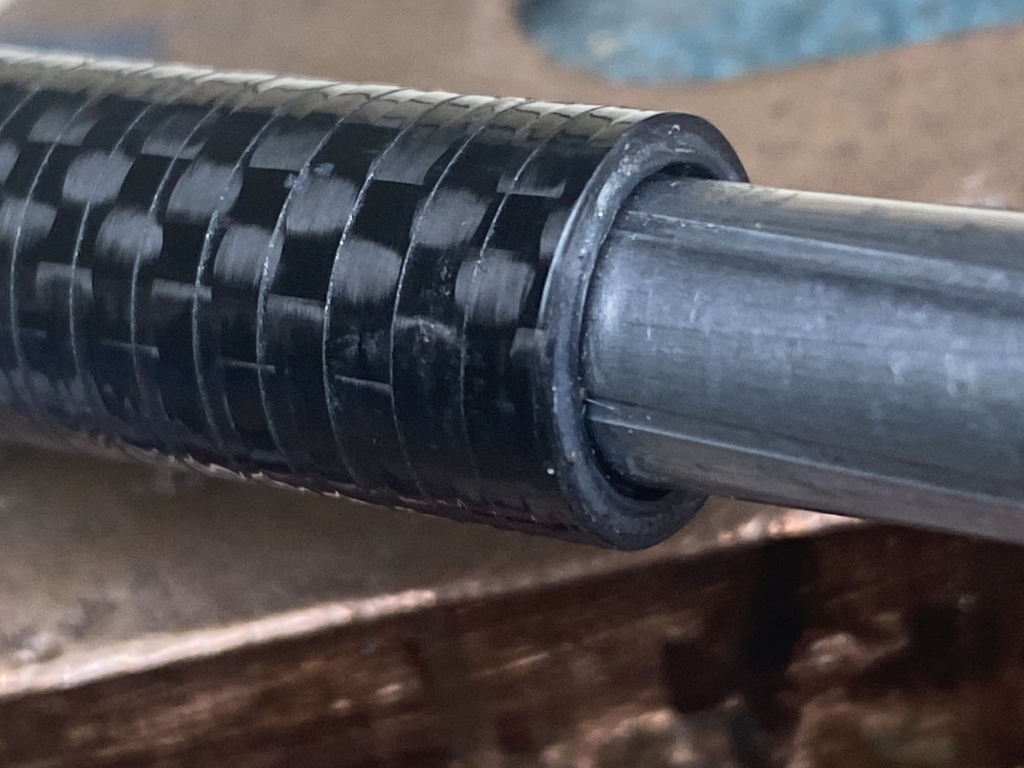

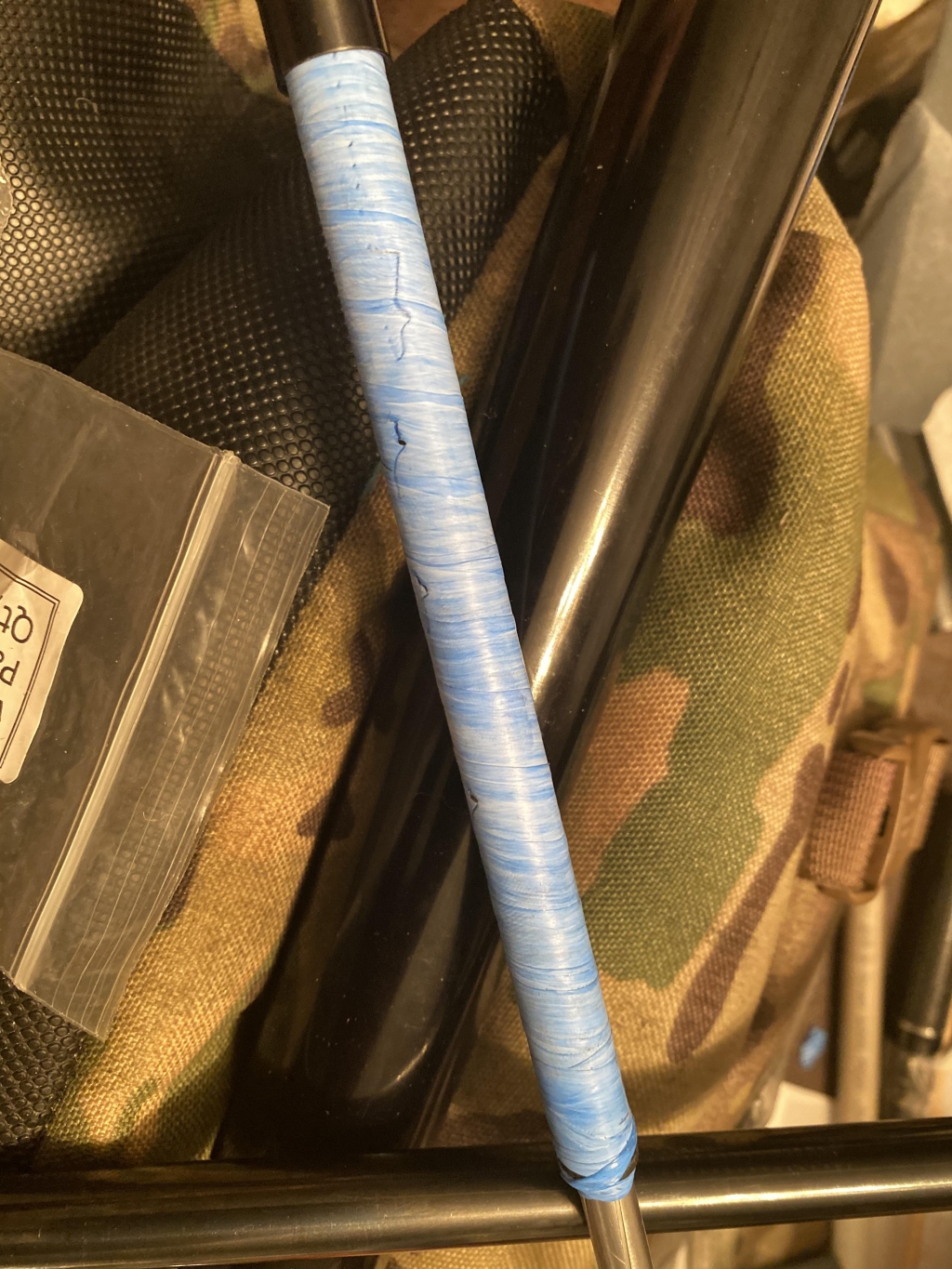

Knowing that I'd never get these 36-40gr to shoot better than 1.25" @100m with my reg set there, I figured now was the time to stiffen this liner up. So I put together a system using two high quality American made carbon fiber tubes - one thinner one to go around the liner and another thicker high modulus to sleeve that one with. For adhesive, I decided this time I would use Loctite EA E-120HP, aerospace-grade Hysol with a 120-minute working time.

Pain in the ass project, but now this barrel kit feels about as stiff as any other airgun barrels that I have had.

So now the FX liner is setup better for high power and heavy lead. Now for the ammo, the .217 Griffin 40 grain boat tails are fairly long by airgun "slug" standards in this caliber. When I first saw them, I wondered if they would even fit in the Taipan mags, but sure enough I had just enough room to spare:

My new valve's PEEK poppet is broken in finally, no slow leakage to deal with, so now all I needed to do was up the reg pressure and figure out how I would crack open the valve (and just long enough) to launch those bad boys faster than I had them going before. To do that, a brass hammer weight is definitely required, along with a heavier hammer spring and (1) a heavier valve spring or (2) valve spring tension. I made a new hammer weight with marine brass, and a rear pre-tension bushing out of Delrin. I made a spring for it that would provide enough muscle to drive it all.

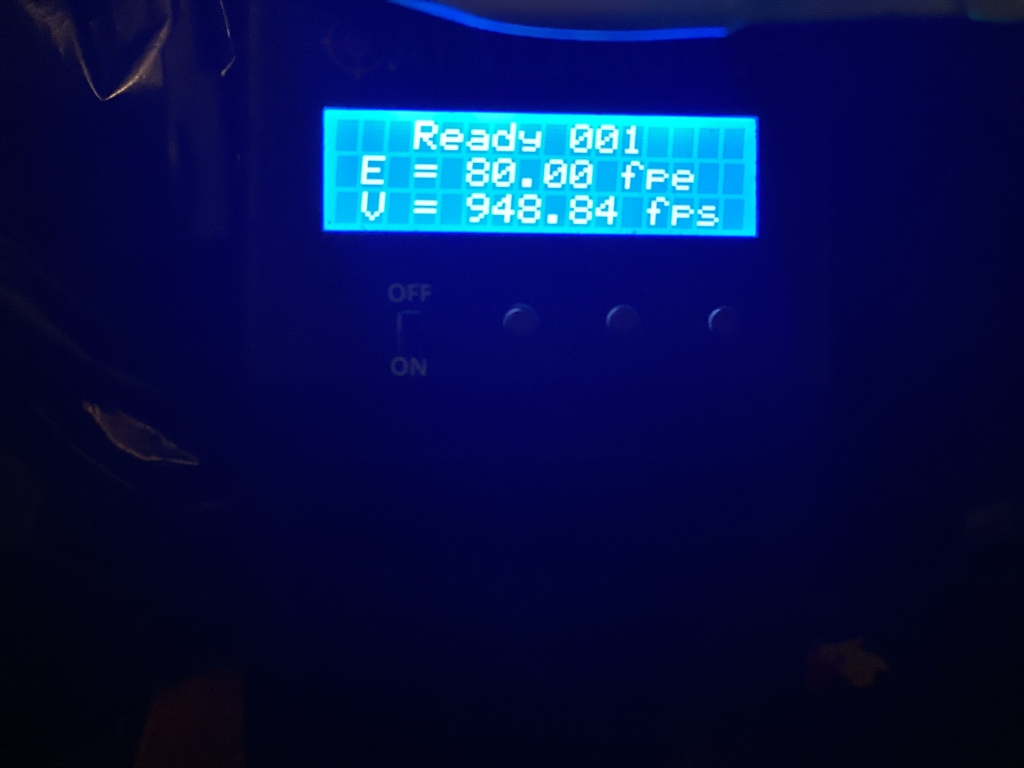

The setup I ran before was only good for 165bar. I was anxious to test this over my chrono to see if I would break my Vet's previous 72FPE record..

First shot - 80FPE!!! Before I even looked at the numbers, I could definitely hear the difference between this and the previous tune

Not bad for a 22 cal Taipan with a 600mm barrel. I still have 11-12bar left on the reg to tap into and another new valve in the works, but for now I'll be humbled and call this good

So this week, I decided that I would retune it to see how fast I could get them up to. Harmonics have been a major problem to deal with when shooting 30-36+ grain ammo. I saw that everyone and their mother was sleeving their FX liners with carbon fiber, my first attempt wasn't great - but I realized what I would do next time if I choose to try again.

Knowing that I'd never get these 36-40gr to shoot better than 1.25" @100m with my reg set there, I figured now was the time to stiffen this liner up. So I put together a system using two high quality American made carbon fiber tubes - one thinner one to go around the liner and another thicker high modulus to sleeve that one with. For adhesive, I decided this time I would use Loctite EA E-120HP, aerospace-grade Hysol with a 120-minute working time.

Pain in the ass project, but now this barrel kit feels about as stiff as any other airgun barrels that I have had.

So now the FX liner is setup better for high power and heavy lead. Now for the ammo, the .217 Griffin 40 grain boat tails are fairly long by airgun "slug" standards in this caliber. When I first saw them, I wondered if they would even fit in the Taipan mags, but sure enough I had just enough room to spare:

My new valve's PEEK poppet is broken in finally, no slow leakage to deal with, so now all I needed to do was up the reg pressure and figure out how I would crack open the valve (and just long enough) to launch those bad boys faster than I had them going before. To do that, a brass hammer weight is definitely required, along with a heavier hammer spring and (1) a heavier valve spring or (2) valve spring tension. I made a new hammer weight with marine brass, and a rear pre-tension bushing out of Delrin. I made a spring for it that would provide enough muscle to drive it all.

The setup I ran before was only good for 165bar. I was anxious to test this over my chrono to see if I would break my Vet's previous 72FPE record..

First shot - 80FPE!!! Before I even looked at the numbers, I could definitely hear the difference between this and the previous tune

Not bad for a 22 cal Taipan with a 600mm barrel. I still have 11-12bar left on the reg to tap into and another new valve in the works, but for now I'll be humbled and call this good