A little background on how this gun came to be....

https://www.airgunnation.com/topic/veteran-long-22-rebarrel/#post-1180157

This one is somewhat of a fortunate accident. Friend machined up that 24inch .177 polygonal for me to do some testing in my .22 Long. I was swapping the unchoked .22 LW and the poly .177 back and forth on the Long and trying to be ready for monthly XFT matches with the .22 and, well, I guess I'm something like 0/5 on making the single gun/multiple barrels thing work. On paper it looks great, but swapping back and forth is a pain. So, a .22 coffee Lam Standard came up used on the classifieds and I bought it, with the intent to make a dedicated .177 Veteran and letting the Long stay a dedicated .22 for the MRDs.

The .22 Long (the "Long Ranger" in the post referenced above) now has the coffee lam stock from the used Standard and the pepper lam from the .22 Long got moved to the .177 Standard.

Currently the regulator pressure of the .177 Standard is OEM 125bar. With some chrono work I concluded that it'll just barely shoot a tight enough ES @ regular field target legal level of just under 20fpe. Spreads of around 25fps with JSB 10.34s at an average of 920fps with hardly any hammer tension, seems like most of the hammer tension adjustment plug is sticking out the back of the gun-can probably see 4 threads. Ideally it probably needs the regulator down around 100 or maybe 110 for really tight ES as a dedicated sub 20fpe field target gun. BUT I still want to play with it shooting heavy .177s and might even go the other direction with the reg pressure to see how it'll sling the 20.5grain NSAs. Even with 125 bar reg pressure it'll push the 16.2grain JSBs up to 940 but I don't expect it to get the 20.5s moving unless the regulator is up around 150bar. I will eventually find out for sure vs speculating.

The barrel looks too long for the air tube but it balances surprisingly well, given the 10mm OD barrel and carbon fiber. That CF saves a ton of weight! Total length is 34 inches, and nearly an inch of that is the 3d printed butt pad. Anybody with a complaint about the heft of a Veteran should consider this CF configuration, REALLY cuts down the overall weight. Lots of steel (weight) in those 15mm factory Taipan barrels.

Gun is topped off with an ever-trusty SWFA 20x. 3d printed buttpad from Bryan Samson. UTG front grip being used as a make-shift knee riser. Tube is the Veteran Standard length tube. No plenum addition. OEM hammer spring.

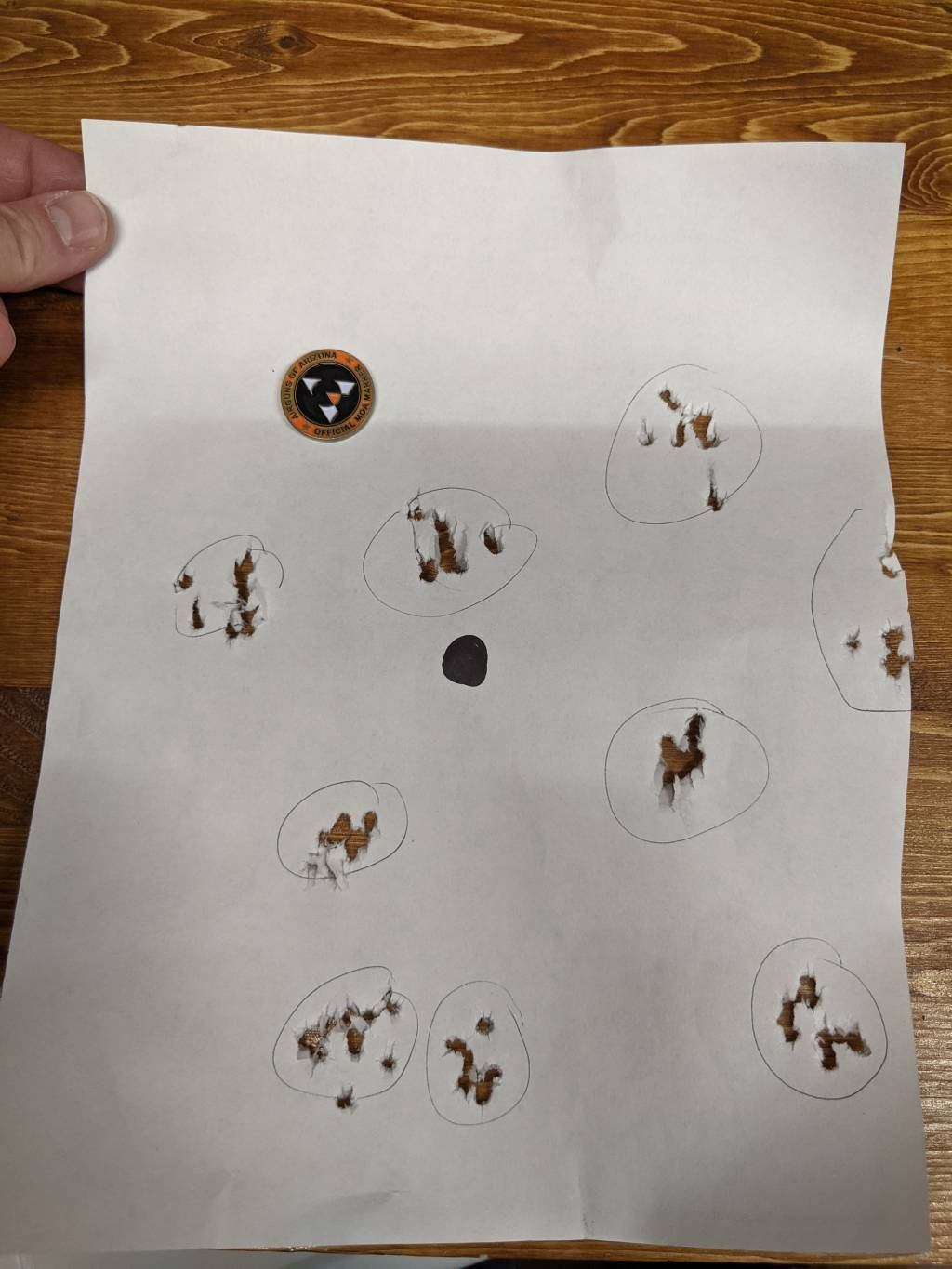

I had about 30 minutes of daylight last night after work and plopped down on a bumbag to see what it'd do. As cited above, averaging 920fps with JSB 10.34. Shot 9, 10 shot groups at 55 yards from field target position. Not sure if they should be considered 9 shot groups though, cuz the first shot of each group was to make a pellet hole/aim point. The tighter groups were before the light started failing and I could see that .177 pellet hole that I was aiming for. Overall quite pleased with the accuracy. Plenty accurate for field target. Shot from a bench it'd be all pellets touching.

Gotta love Vets. Properly adjusted trigger is just a perfect two stage feel, take up that first stage and then nice and crisp and predictable on the break. Firing characteristics of airguns aren't often discussed but I feel like that's a large part of why the Vet has a cult following. They're just so dead to shoot. Calm as can be, no bucking bronco with a Veteran (even at higher power they're really docile to shoot). Pellet is gone quick and crosshairs stay right on the impact point through the shot and as the pellet gets where it's going. Just a surreal, thoroughly enjoyable shooting experience.

Current plan for the .177 Standard VET...

Edit: forgot to add shot count info. I started with gun filled to just under 250 bar and ended with it just under 150 bar, so call it 245 bar to 145 bar. 90 shots. Probably another good 20 shots before getting below reg pressure of 125. Not that efficient when compared to my Vet Short @ 20 fpe (either .22 or .20). But again, I think with a lower regular pressure on a dedicated 20fpe tune and the shot count would go up to around 140 shots per fill @ 20fpe.

https://www.airgunnation.com/topic/veteran-long-22-rebarrel/#post-1180157

This one is somewhat of a fortunate accident. Friend machined up that 24inch .177 polygonal for me to do some testing in my .22 Long. I was swapping the unchoked .22 LW and the poly .177 back and forth on the Long and trying to be ready for monthly XFT matches with the .22 and, well, I guess I'm something like 0/5 on making the single gun/multiple barrels thing work. On paper it looks great, but swapping back and forth is a pain. So, a .22 coffee Lam Standard came up used on the classifieds and I bought it, with the intent to make a dedicated .177 Veteran and letting the Long stay a dedicated .22 for the MRDs.

The .22 Long (the "Long Ranger" in the post referenced above) now has the coffee lam stock from the used Standard and the pepper lam from the .22 Long got moved to the .177 Standard.

Currently the regulator pressure of the .177 Standard is OEM 125bar. With some chrono work I concluded that it'll just barely shoot a tight enough ES @ regular field target legal level of just under 20fpe. Spreads of around 25fps with JSB 10.34s at an average of 920fps with hardly any hammer tension, seems like most of the hammer tension adjustment plug is sticking out the back of the gun-can probably see 4 threads. Ideally it probably needs the regulator down around 100 or maybe 110 for really tight ES as a dedicated sub 20fpe field target gun. BUT I still want to play with it shooting heavy .177s and might even go the other direction with the reg pressure to see how it'll sling the 20.5grain NSAs. Even with 125 bar reg pressure it'll push the 16.2grain JSBs up to 940 but I don't expect it to get the 20.5s moving unless the regulator is up around 150bar. I will eventually find out for sure vs speculating.

The barrel looks too long for the air tube but it balances surprisingly well, given the 10mm OD barrel and carbon fiber. That CF saves a ton of weight! Total length is 34 inches, and nearly an inch of that is the 3d printed butt pad. Anybody with a complaint about the heft of a Veteran should consider this CF configuration, REALLY cuts down the overall weight. Lots of steel (weight) in those 15mm factory Taipan barrels.

Gun is topped off with an ever-trusty SWFA 20x. 3d printed buttpad from Bryan Samson. UTG front grip being used as a make-shift knee riser. Tube is the Veteran Standard length tube. No plenum addition. OEM hammer spring.

I had about 30 minutes of daylight last night after work and plopped down on a bumbag to see what it'd do. As cited above, averaging 920fps with JSB 10.34. Shot 9, 10 shot groups at 55 yards from field target position. Not sure if they should be considered 9 shot groups though, cuz the first shot of each group was to make a pellet hole/aim point. The tighter groups were before the light started failing and I could see that .177 pellet hole that I was aiming for. Overall quite pleased with the accuracy. Plenty accurate for field target. Shot from a bench it'd be all pellets touching.

Gotta love Vets. Properly adjusted trigger is just a perfect two stage feel, take up that first stage and then nice and crisp and predictable on the break. Firing characteristics of airguns aren't often discussed but I feel like that's a large part of why the Vet has a cult following. They're just so dead to shoot. Calm as can be, no bucking bronco with a Veteran (even at higher power they're really docile to shoot). Pellet is gone quick and crosshairs stay right on the impact point through the shot and as the pellet gets where it's going. Just a surreal, thoroughly enjoyable shooting experience.

Current plan for the .177 Standard VET...

- Eventually do some head to head in the wind with this .177 polygonal barrel versus the one on my USFT. I've always been in awe at how well that poly barrel in the USFT resists the wind so it'll be interesting to see if the same characteristic can be seen from this barrel. It should be a very fair comparison. They're the same length, both have slight choke, can be set up to shoot at identical power levels, both from guns with great triggers and consistent ES. Both barrels like the JSB 10.34. Also curious to know if the BC is any different from one .177 poly to the next, given every other variable being nearly identical. Should be fun.

- Might just compete with it for some of the low power field target matches this summer.

- Also want to experiment more with the .177 slugger idea. Have a couple boxes of the 20.5grain NSAs and I'm excited for that too, especially after Arzrover's impressive long range results and high BC measurements from a couple weeks back.

- Final configuration will be decided upon by results from above testing.

Edit: forgot to add shot count info. I started with gun filled to just under 250 bar and ended with it just under 150 bar, so call it 245 bar to 145 bar. 90 shots. Probably another good 20 shots before getting below reg pressure of 125. Not that efficient when compared to my Vet Short @ 20 fpe (either .22 or .20). But again, I think with a lower regular pressure on a dedicated 20fpe tune and the shot count would go up to around 140 shots per fill @ 20fpe.