Well, by now, I've fired probably a whole tin of pellets through the stock TX200. (US spec @ 16 FPE) After a couple hundred break-in rounds, accuracy picked up. But it was quite twangy, and pretty high effort to cock. I read a lot, that reducing the power and tuning it would result in higher accuracy yet and eliminate the twanginess.

So I bought the 12 FPE Vortek kit and put it in there. The instruction sheet, in my opinion is barely adequate. It has a rudimentary diagram that is probably applicable to all of their kits. But I think at $70 for a spring, an O-ring, a few washers and such, they should have custom installation sheets for each rifle. It's probably well under $10 worth of hardware, once the tooling is paid for. It wouldn't take them long to do. Maybe it is their way of discouraging those who aren't handy to take it on themselves? Here's the specific shortfall areas:

I haven't tried all the pellets again; I only tried a few that it liked before, and I omitted the 10+ gr. ones, because they're not really power-appropriate any more.

The pellets I tried were:

There were variable winds, but I feel like they didn't effect things much.

I might pop it apart again and put in one of the preload washers, to see if I can get it closer to 12 FPE, while still being under. But I'll wait until it is fully broken in and see where things lie.

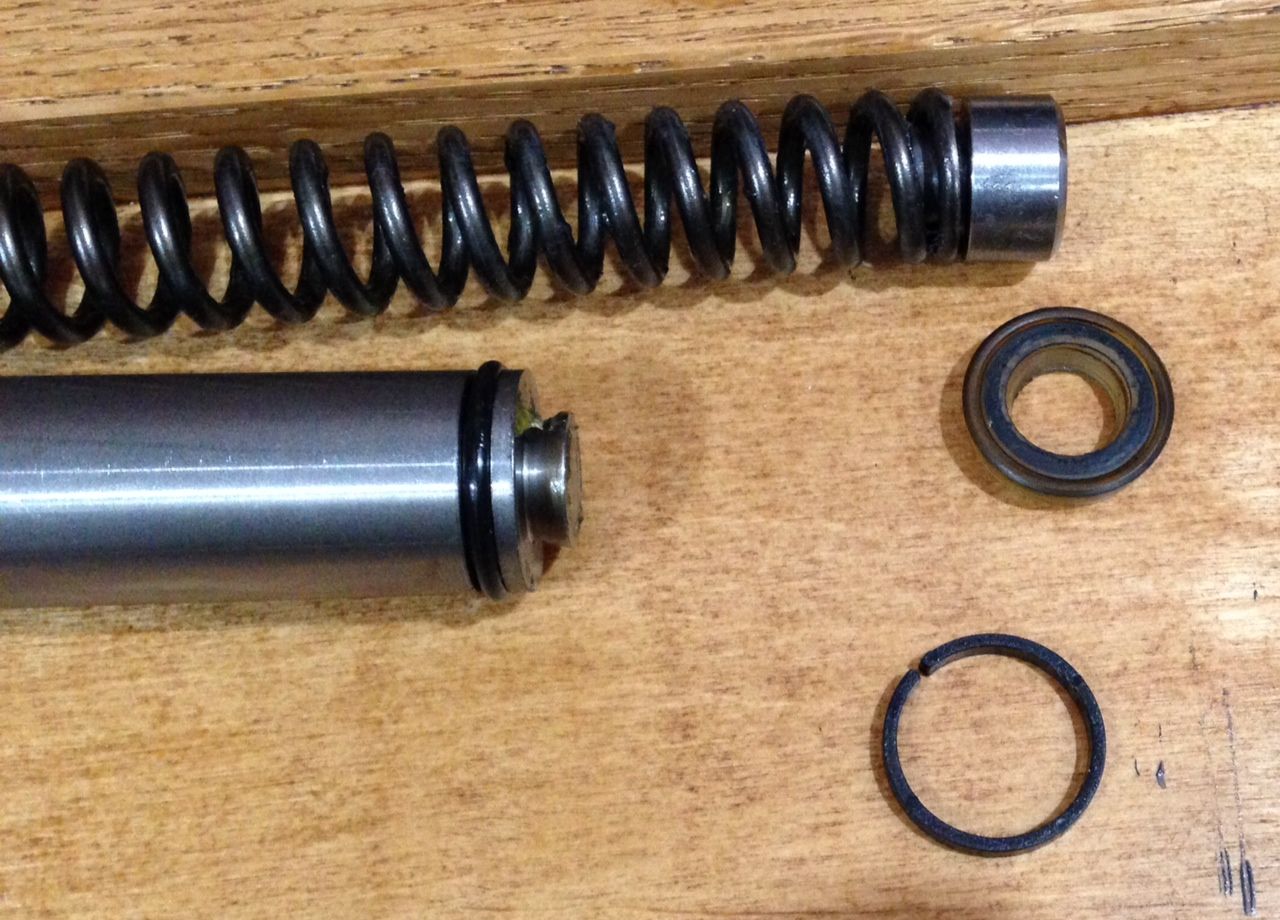

So I bought the 12 FPE Vortek kit and put it in there. The instruction sheet, in my opinion is barely adequate. It has a rudimentary diagram that is probably applicable to all of their kits. But I think at $70 for a spring, an O-ring, a few washers and such, they should have custom installation sheets for each rifle. It's probably well under $10 worth of hardware, once the tooling is paid for. It wouldn't take them long to do. Maybe it is their way of discouraging those who aren't handy to take it on themselves? Here's the specific shortfall areas:

- Preload washers (for more power) are included, but it is not said or shown where to put them. I knew this from watching another YouTube video, but it should be in the instruction sheet.

- It doesn't say or show to replace the piston seal, and the Vortek seal looks pretty different than stock

- It doesn't say where the O-ring goes. It could either go on the outside of the piston, to replace one of the split plastic rings, or below the piston seal. Luckily, it won't go back together if it replaces the plastic split ring, so it was a process of elimination for me. But I worry a bit that I may have damaged that O-ring while trying to put it back together! In the end, I don't think it matters, because the purpose of that O-ring seems to be vibration dampening, rather than sealing anything.

- Although the kit is specific to the TX200, there are no instructions provided on how to take apart the TX200. I found a great and simple YouTube video on it. It shouldn't be necessary.

I haven't tried all the pellets again; I only tried a few that it liked before, and I omitted the 10+ gr. ones, because they're not really power-appropriate any more.

The pellets I tried were:

- RWS Basic, 7.0 gr. wadcutters. Gotta try a basic wadcutter, right? These were shooting at about 820 fps, average. Not too accurate; probably a little too fast for wadcutters. Will try RWS SuperMag and Meisterkugeln Rifle next.

- CPL, 7.9 gr.: Averaged about 760 fps., 10.4 FPE, but varied from 740s to 770s. Might have something to do with the fact that they picked up a little residual lube from the tin I put them in.

- JSB Exact, 8.44 gr.: 775 fps avg., 11.7 FPE

- AA Diabolo Express, 7.9 gr.: 790 fps avg., 11.0 FPE

- AA Diabolo Field, 8.4 gr.: 770 fps avg., 11.1 FPE

There were variable winds, but I feel like they didn't effect things much.

- 55 yards, AA Diabolo Field 4.51, 10 shots, 1-15/16"

- 25 yards, Exact, 10 shots, 3/4"

- 14 yards, AA DF 4.51, 10 shots 5/16"

I might pop it apart again and put in one of the preload washers, to see if I can get it closer to 12 FPE, while still being under. But I'll wait until it is fully broken in and see where things lie.