where can one find the stl and check valve?Yeah I'm thinking of adding a fan to cool the fist tower and the coiled stainless tube that feeds it. Can't hurt.

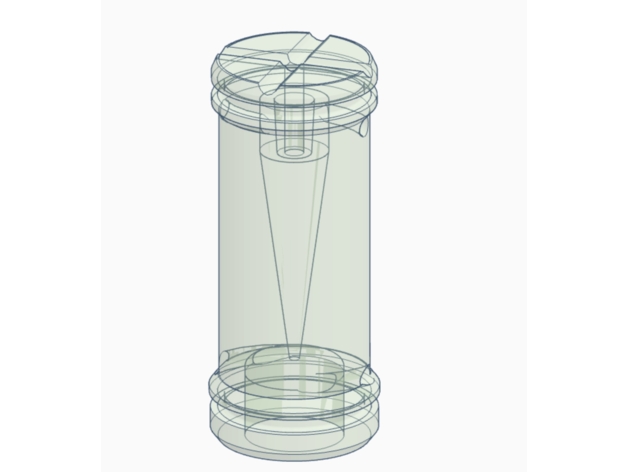

The baffle works great. With it in place, there is no need to open the first tower too often. The cotton just stays dry and clean. Should I release the stl?

I would not go too crazy with heat on the aluminum tube that contains 300 bar... I got mines off using a pipe wrench. Marred the finish on one tube a little, oh well.

Upvote 0