A good friend machined a perfectly snug fitting guide. The shot cycle is now buttery smooth!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Tuning Tuned the FWB Sport and Wow

- Thread starter Soloshot

- Start date

Hold on a minute now.....

What about this statement you made in the thread about tuning springers?

"Just get a fwb sport. No "tune" required "

"

What about this statement you made in the thread about tuning springers?

"Just get a fwb sport. No "tune" required

Upvote 0

Ask him kindly to make another one! I’d love try one out myself as mine could use a little help.

Upvote 0

I've got the same rifle. Cocking noise is ridiculous. spring buzz is extreme. Was yours as bad as what you see in my video? If so, I'd love the details on what dimensions were used in machining that new guide.

https://youtu.be/nXQbPnx3hh8

https://youtu.be/nXQbPnx3hh8

Upvote 0

I've got the same rifle. Cocking noise is ridiculous. spring buzz is extreme. Was yours as bad as what you see in my video? If so, I'd love the details on what dimensions were used in machining that new guide.

https://youtu.be/nXQbPnx3hh8

What scope mounts did you use ?

Upvote 0

Sports Match with the crosspin that's supposed to engage with the radial groves in the Sport's receiver. I can't remember the exact part number.

Upvote 0

I bought mine tuned from Flying Dragons. Mike made a spring guide. Maybe he can send you one. Mine shoots great.

Upvote 0

Thanks Don, However, I've got access to a lathe so I'm interested in seeing if I can turn one out myself. I'm not a machinist but I think I'm up to the task. We'll find out when my delrin rod arrives. I'll have some footage of the process in an upcoming video. Really appreciate your viewership. Don't forget to subscribe!

Upvote 0

Out of the box, that FWB sounds terrible, but very fixable ... trigger guard replacement is the real problem.

Does anyone make a aftermarket replacement?

Does anyone make a aftermarket replacement?

Upvote 0

Hold on a minute now.....

What about this statement you made in the thread about tuning springers?

"Just get a fwb sport. No "tune" required "

"

That is correct Thumper, the accuracy was phemoninal with a slight buzz in the shot cycle. I was shooting with my buddy and he offered to design and install the guide right then and there to smooth out the shot cycle even more. 3 hours later we were done.

So the gun has been opened twice, first was just adding some moly as it came to me very dry. This lube only addition made the cocking action and shot cycle noticeably better and smoother (accuracy remained same). The 2nd time I dismantled in my friend's garage where he measured the stock guide and designed/turned a new piece with tighter tolerances to spring ID and piston rod OD. The result made cocking soundless smooth and eliminated the remaining buzz from the shot cycle.

Upvote 0

I've got the same rifle. Cocking noise is ridiculous. spring buzz is extreme. Was yours as bad as what you see in my video? If so, I'd love the details on what dimensions were used in machining that new guide.

https://youtu.be/nXQbPnx3hh8

Razor62,

When I recieved the gun the cocking was not smooth and shot cycle a bit harsh. Cocking got worse in about 30 shots and I thought maybe the spring broke. When took it apart, it was very dry inside with everything intact. Added some grease with paint brush to cylinder surface, cicking shoe, guide, spring and reassembled. Cocking and shot cycle improved a lot.

The guide is metal with washer held in place by a circlip in a groove. The gap between guide/spring and guide/piston rode is big, source of buzz in shot cycle. Turning a new guide tightened these tolerances but took a lot of detail work to match the profile that mates with the trigger block end.

In your case, there are 2 options. First is to dismantle and lightly grease metal to metal contact surfaces, polish spring ends. This will make the gun cycle noticeably better. I was happy at this stage. 2nd option is to build/buy a guide and add to above. Building the guide is not trivial so if available from Flying Dragons it is the best option.

Upvote 0

Interesting. Mine came lubed with moly but not too much. The rifle is dismantled now. I've removed two coils from the mainspring to tame her down some and I plan to "Try" to machine a spring guide before I use Mike as option B. I'm just hoping to be able to turn out a well tuned gun by myself. Kind of a personal challenge. I'll be documenting the process on video so keep an eye on my channel. I'm not completely without experience using a lathe so, fingers crossed...

I really appreciate your taking the time to reply. I'll put your advice to good use.

Happy New Year!

https://youtube.com/user/razor1962

I really appreciate your taking the time to reply. I'll put your advice to good use.

Happy New Year!

https://youtube.com/user/razor1962

Upvote 0

Razor62,

Very curious to hear the fpe before and after the coil removal. Mine is shooting 15 fpe (stock spring) with JSB 8.44 (900 fps) and targetting 12-13 fpe with some trigger work may be the next step but I want to run it in a match first to get a baseline, the accuracy is very impressive even at 15 fpe power.

I talked to my friend about the interest in the details and he may be able to help as I have zero machining experience. Looking forward to your project, new year to you too.

Very curious to hear the fpe before and after the coil removal. Mine is shooting 15 fpe (stock spring) with JSB 8.44 (900 fps) and targetting 12-13 fpe with some trigger work may be the next step but I want to run it in a match first to get a baseline, the accuracy is very impressive even at 15 fpe power.

I talked to my friend about the interest in the details and he may be able to help as I have zero machining experience. Looking forward to your project, new year to you too.

Upvote 0

I wrote about my experience with the FWB Sport here:

https://www.airgunnation.com/topic/more-observations-on-the-fwb-sport/#post-1033132

In my review I discussed the evolution of the spring guide that currently resides in my rifle.

I'm pretty sure I used mild steel, though it could have been stainless. I think mild steel is perfectly fine and I have no doubt that delrin will work very well also. The hardest part, I thought, was drilling that deep hole without the drill wandering. If I recall, I drilled part way then turned the piece around and continued drilling from the opposite end. It worked perfectly.

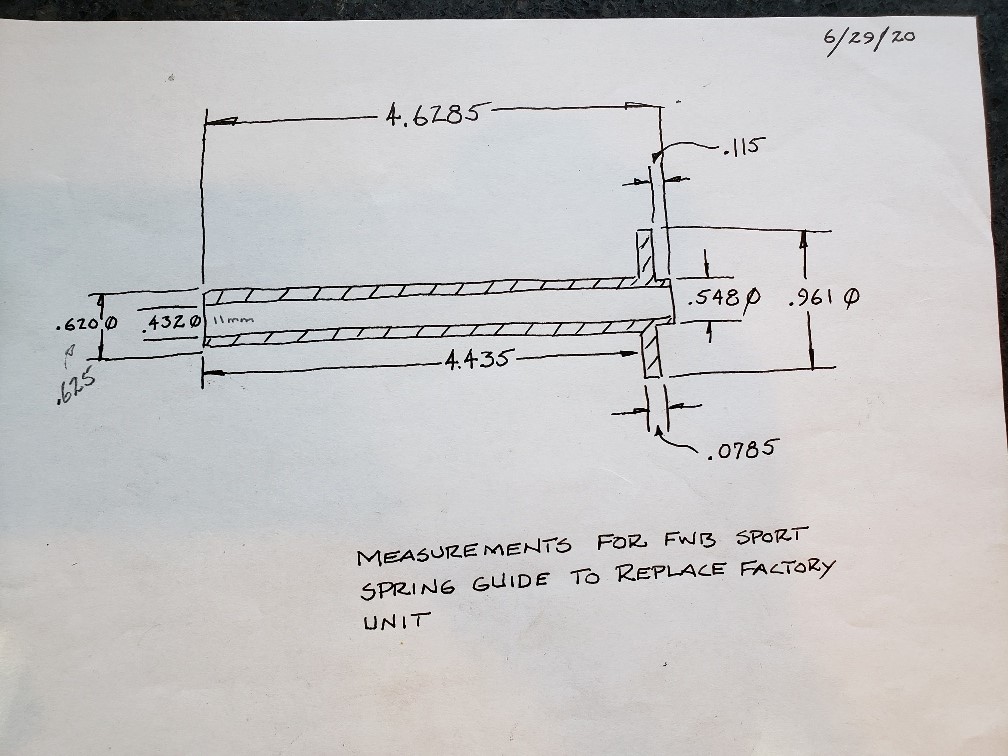

Here are the dimensions I used should anyone be interested. Beyond the increased diameter of the guide surface all measurements are the same as you would find on the original spring guide. Also, I did away with the three pieces as found in the original assembly. Obviously some of the measurements are more precise than they need to be, but I was trying to replicate exactly those dimensions found on the existing guide so I would have a baseline during the manufacture of my own. You may notice that I eschewed the .620 diameter measurement on my drawing in favor of .625. That gave me a bit of an interference fit between the spring and the guide. As I'm sure anyone who has ever done this sort of thing can imagine, I made it so that I had to kind of "screw" the spring onto the guide. Why FWB engineers allowed the inside of these rifles to be such rattletraps still baffles me when it really is such an easy fix.

Of course all airguns are slightly different, but I'd be willing to bet that these dimensions will work with all FWB Sport rifles.

Once I added this guide to the internals of the rifle, it completely eliminated spring noise while cocking. It's silent now, Stealthy, in fact. Also, as others have mentioned, it did away with the rather epic buzz.

https://www.airgunnation.com/topic/more-observations-on-the-fwb-sport/#post-1033132

In my review I discussed the evolution of the spring guide that currently resides in my rifle.

I'm pretty sure I used mild steel, though it could have been stainless. I think mild steel is perfectly fine and I have no doubt that delrin will work very well also. The hardest part, I thought, was drilling that deep hole without the drill wandering. If I recall, I drilled part way then turned the piece around and continued drilling from the opposite end. It worked perfectly.

Here are the dimensions I used should anyone be interested. Beyond the increased diameter of the guide surface all measurements are the same as you would find on the original spring guide. Also, I did away with the three pieces as found in the original assembly. Obviously some of the measurements are more precise than they need to be, but I was trying to replicate exactly those dimensions found on the existing guide so I would have a baseline during the manufacture of my own. You may notice that I eschewed the .620 diameter measurement on my drawing in favor of .625. That gave me a bit of an interference fit between the spring and the guide. As I'm sure anyone who has ever done this sort of thing can imagine, I made it so that I had to kind of "screw" the spring onto the guide. Why FWB engineers allowed the inside of these rifles to be such rattletraps still baffles me when it really is such an easy fix.

Of course all airguns are slightly different, but I'd be willing to bet that these dimensions will work with all FWB Sport rifles.

Once I added this guide to the internals of the rifle, it completely eliminated spring noise while cocking. It's silent now, Stealthy, in fact. Also, as others have mentioned, it did away with the rather epic buzz.

Upvote 0

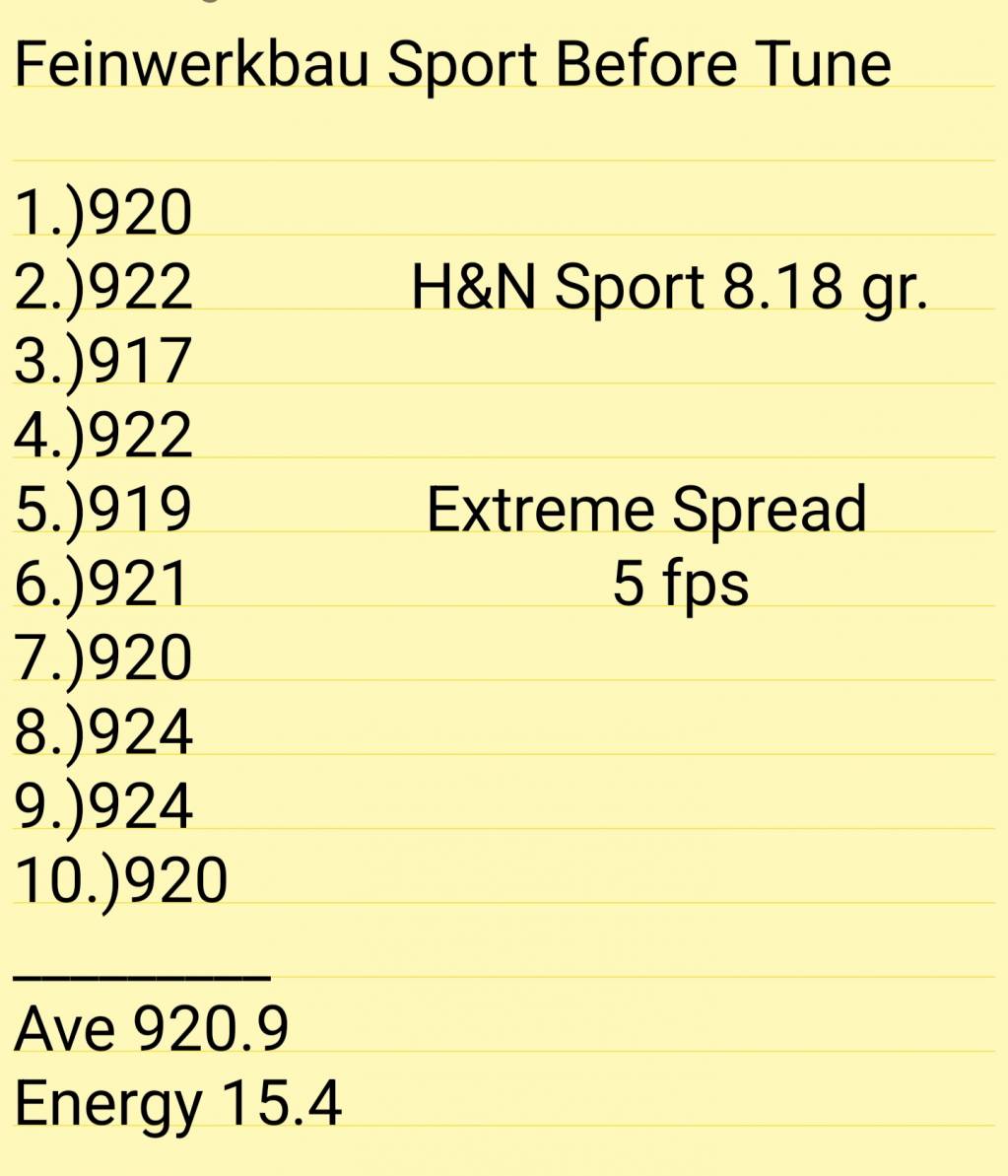

Here's the "before" numbers. I'll be sure to post the "after" numbers in my upcoming video.

Upvote 0

Phillip, this is awesome! I can't thank you enough. I'll definitely be using these measurements. Can't wait to get this rifle shooting the way it should.

Upvote 0

Machined a new spring guide from delrin. Fit is snug with the spring, requiring a small amount of pressure to install the guide. Was gonna' make top hat but the piston rod has a shoulder where it connects to the piston head. Because of it's location, it's nearly impossible to take measurements. Opted instead to sleeve the piston using the "soda bottle" technique. Spring fits snugly into the piston now with zero play. No idea how long the sleeve will last. Hopefully a long time. Cut 1,1/2 coils from the mainspring. Lubed the piston seal, the cocking shoe rails, and the ends of the spring with moly. lubed the spring itself with some leftover grease that I had on hand from a Vortek tune kit that I installed in my HW97K. Reassembled the rifle and tentatively cocked the action. Cocking is silent with only the sound of the sear engaging as the stroke comes to a stop. Firing cycle is fast with zero vibration---ZIP!!! Couldn't be more pleased. Also installed new BKL double strap rings with a scope stop (locking pin omitted). We'll see if the scope stays put now. Opted to stick with my relatively heavy, 25 oz Hawke 4-12 X 40mm. If it moves again, my only option will be to use a lighter the scope and try again. Open sights are not an option for these old eyeballs.

There'll be a video soon which will document the process. Keep an eye out or better yet, subscibe to my YouTube channel and hit the bell for notification each time that I release a new video. https://www.youtube.com/user/razor1962

In any case, the rifle is shooting as it should and now I can begin to enjoy shooting it. The way it was as received made it impossible for me to enjoy the shooting experience.

Just want to thank the OP for starting this thread as well as all of the folks who contributed to it. Thanks so much and HAPPY NEW YEAR!

There'll be a video soon which will document the process. Keep an eye out or better yet, subscibe to my YouTube channel and hit the bell for notification each time that I release a new video. https://www.youtube.com/user/razor1962

In any case, the rifle is shooting as it should and now I can begin to enjoy shooting it. The way it was as received made it impossible for me to enjoy the shooting experience.

Just want to thank the OP for starting this thread as well as all of the folks who contributed to it. Thanks so much and HAPPY NEW YEAR!

Upvote 0