Here is what I learned:

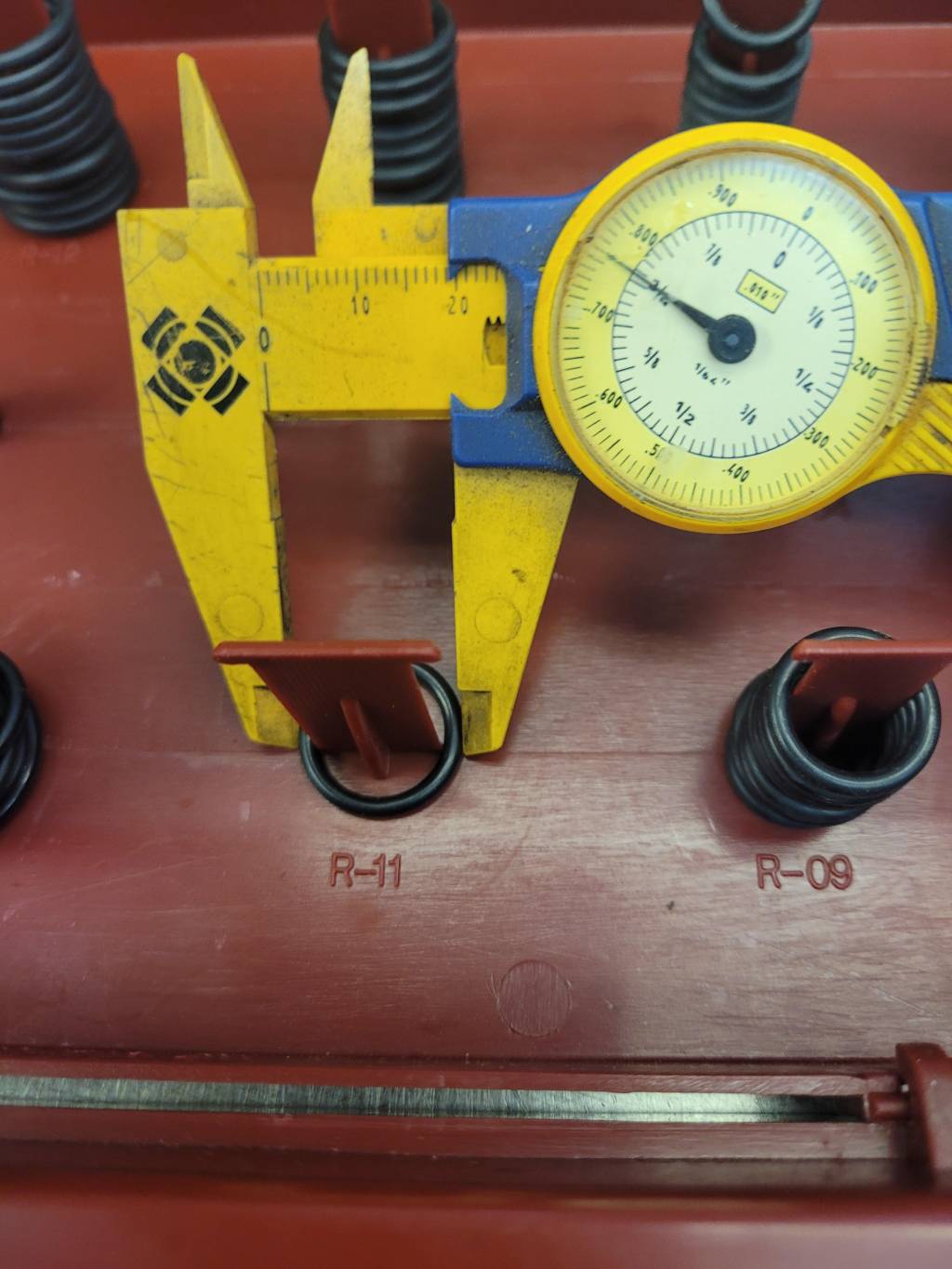

With the original tune using CPHP in 14.3gr, 6 1/2 HS and 3/4 HT = 365fps @ 3000psi with these o rings. Without 425fps so I know they are making contact with the hammer. There does seem to be less spring "twang" and/or valve chatter in the gun.

Without 425fps so I know they are making contact with the hammer. There does seem to be less spring "twang" and/or valve chatter in the gun.

To get the numbers back up to stock and over where it was I had to crank the HS to 8 and the HT to 1 1/2. The first shot @ 3000 was 437. Like stock it started to wake up at about 2300 peaking at 609fps and like stock it has a curve (slightly flatter) with the shot count remaining the same down to 1000; 64.

I welcome all thoughts and comments. How much difference does smoothing off the edges of the ports make? I've done port work old VWs, not that there is much comparison, but I know smooth air flow helps with performance

With the original tune using CPHP in 14.3gr, 6 1/2 HS and 3/4 HT = 365fps @ 3000psi with these o rings.

To get the numbers back up to stock and over where it was I had to crank the HS to 8 and the HT to 1 1/2. The first shot @ 3000 was 437. Like stock it started to wake up at about 2300 peaking at 609fps and like stock it has a curve (slightly flatter) with the shot count remaining the same down to 1000; 64.

I welcome all thoughts and comments. How much difference does smoothing off the edges of the ports make? I've done port work old VWs, not that there is much comparison, but I know smooth air flow helps with performance