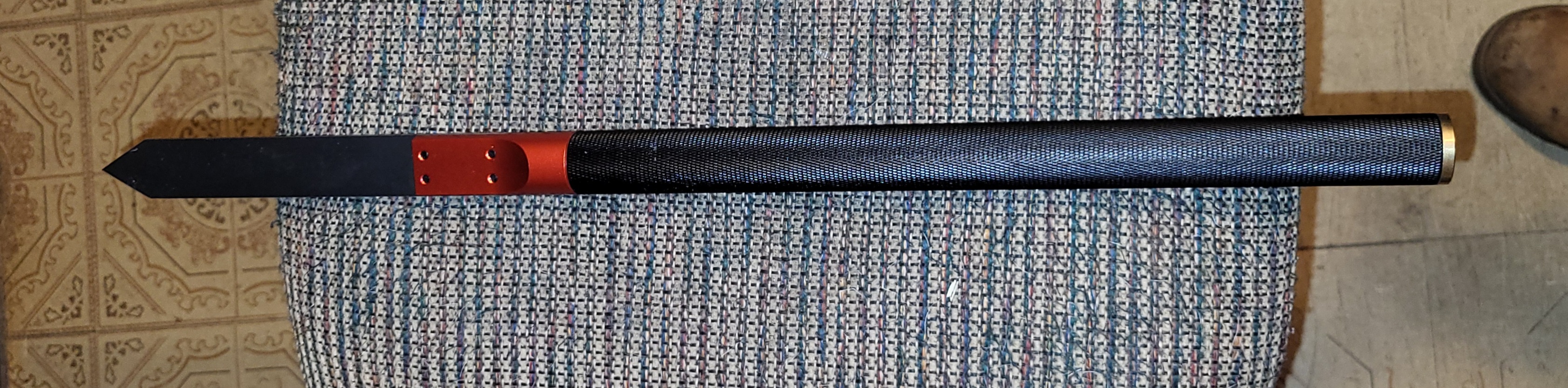

I am 1 of those guy who loves to tinker. Last week I cut 1 coil off the spring in prep for this project. Today, we find out if I can make a spring guide from delrin worth having on a wood lathe...yes is the aanswer.i sold my wood lathe years ago, but still have access to 1. I bought a cheap parting tool off amazon.  it arrived dull, with a light aluminum handle. Sharpened up ok. Unscrewed the handle, and filled with spent lead from my pellet trap...now it actually feels like something worth trying to work with. Cuts surprisingly well, internet claims the 65mn steel is basically Chinese 1095...maybe?

it arrived dull, with a light aluminum handle. Sharpened up ok. Unscrewed the handle, and filled with spent lead from my pellet trap...now it actually feels like something worth trying to work with. Cuts surprisingly well, internet claims the 65mn steel is basically Chinese 1095...maybe? makes quite a mess, but delrin is easy to cut ....really helps fill out your beard though

makes quite a mess, but delrin is easy to cut ....really helps fill out your beard though the base on mine is about double the thickness of the original. Adding back in some spring tension, while still allowing enough room to engage the sear.

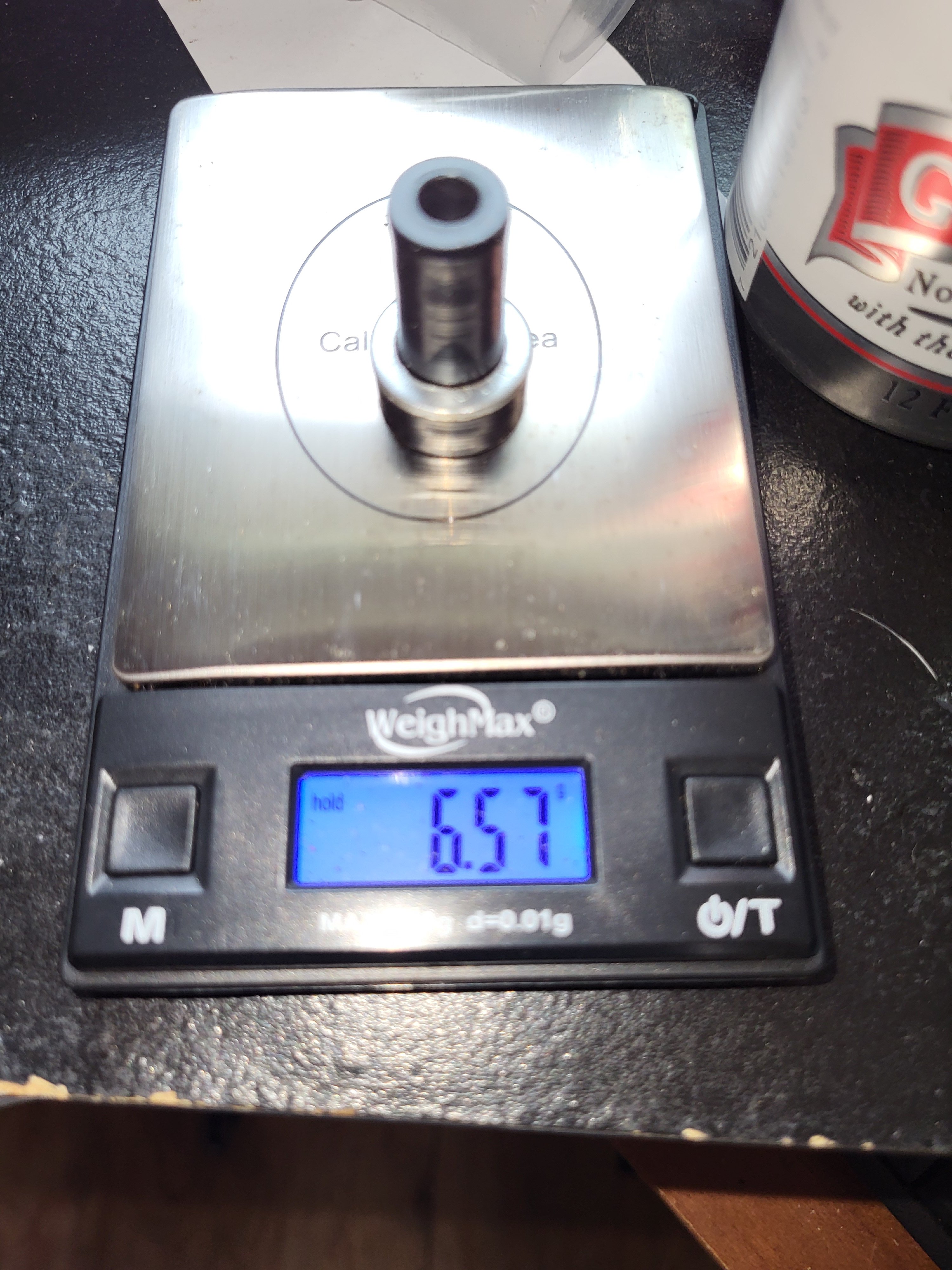

the base on mine is about double the thickness of the original. Adding back in some spring tension, while still allowing enough room to engage the sear. rifle is back together. I have only shot it once as proof of function. Definitely has a different feel to it. Cocking cycle is quieter because of how the sear engages. Before you would bottom out the stroke, hear the sear click into place, then feel/hear the piston move forward a bit before staying locked in place. Now that forward motion is gone. We shall see if this is a good idea or not tomorrow. Should be able to chronograph, and hit a few targets to see where things are at.

rifle is back together. I have only shot it once as proof of function. Definitely has a different feel to it. Cocking cycle is quieter because of how the sear engages. Before you would bottom out the stroke, hear the sear click into place, then feel/hear the piston move forward a bit before staying locked in place. Now that forward motion is gone. We shall see if this is a good idea or not tomorrow. Should be able to chronograph, and hit a few targets to see where things are at.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

N/A Tinker time, cheap tools, and lead

- Thread starter Hold_Over

- Start date

I am easily entertained by tinkerers.I am 1 of those guy who loves to tinker. Last week I cut 1 coil off the spring in prep for this project. Today, we find out if I can make a spring guide from delrin worth having on a wood lathe...yes is the aanswer.i sold my wood lathe years ago, but still have access to 1. I bought a cheap parting tool off amazon.View attachment 461392it arrived dull, with a light aluminum handle. Sharpened up ok. Unscrewed the handle, and filled with spent lead from my pellet trap...now it actually feels like something worth trying to work with. Cuts surprisingly well, internet claims the 65mn steel is basically Chinese 1095...maybe?View attachment 461393makes quite a mess, but delrin is easy to cut ....really helps fill out your beard thoughView attachment 461394the base on mine is about double the thickness of the original. Adding back in some spring tension, while still allowing enough room to engage the sear.View attachment 461395rifle is back together. I have only shot it once as proof of function. Definitely has a different feel to it. Cocking cycle is quieter because of how the sear engages. Before you would bottom out the stroke, hear the sear click into place, then feel/hear the piston move forward a bit before staying locked in place. Now that forward motion is gone. We shall see if this is a good idea or not tomorrow. Should be able to chronograph, and hit a few targets to see where things are at.

Nice work.

Upvote 0

I too use my wood lathe for other purposes . nice jobI am 1 of those guy who loves to tinker. Last week I cut 1 coil off the spring in prep for this project. Today, we find out if I can make a spring guide from delrin worth having on a wood lathe...yes is the aanswer.i sold my wood lathe years ago, but still have access to 1. I bought a cheap parting tool off amazon.View attachment 461392it arrived dull, with a light aluminum handle. Sharpened up ok. Unscrewed the handle, and filled with spent lead from my pellet trap...now it actually feels like something worth trying to work with. Cuts surprisingly well, internet claims the 65mn steel is basically Chinese 1095...maybe?View attachment 461393makes quite a mess, but delrin is easy to cut ....really helps fill out your beard thoughView attachment 461394the base on mine is about double the thickness of the original. Adding back in some spring tension, while still allowing enough room to engage the sear.View attachment 461395rifle is back together. I have only shot it once as proof of function. Definitely has a different feel to it. Cocking cycle is quieter because of how the sear engages. Before you would bottom out the stroke, hear the sear click into place, then feel/hear the piston move forward a bit before staying locked in place. Now that forward motion is gone. We shall see if this is a good idea or not tomorrow. Should be able to chronograph, and hit a few targets to see where things are at.

Upvote 0

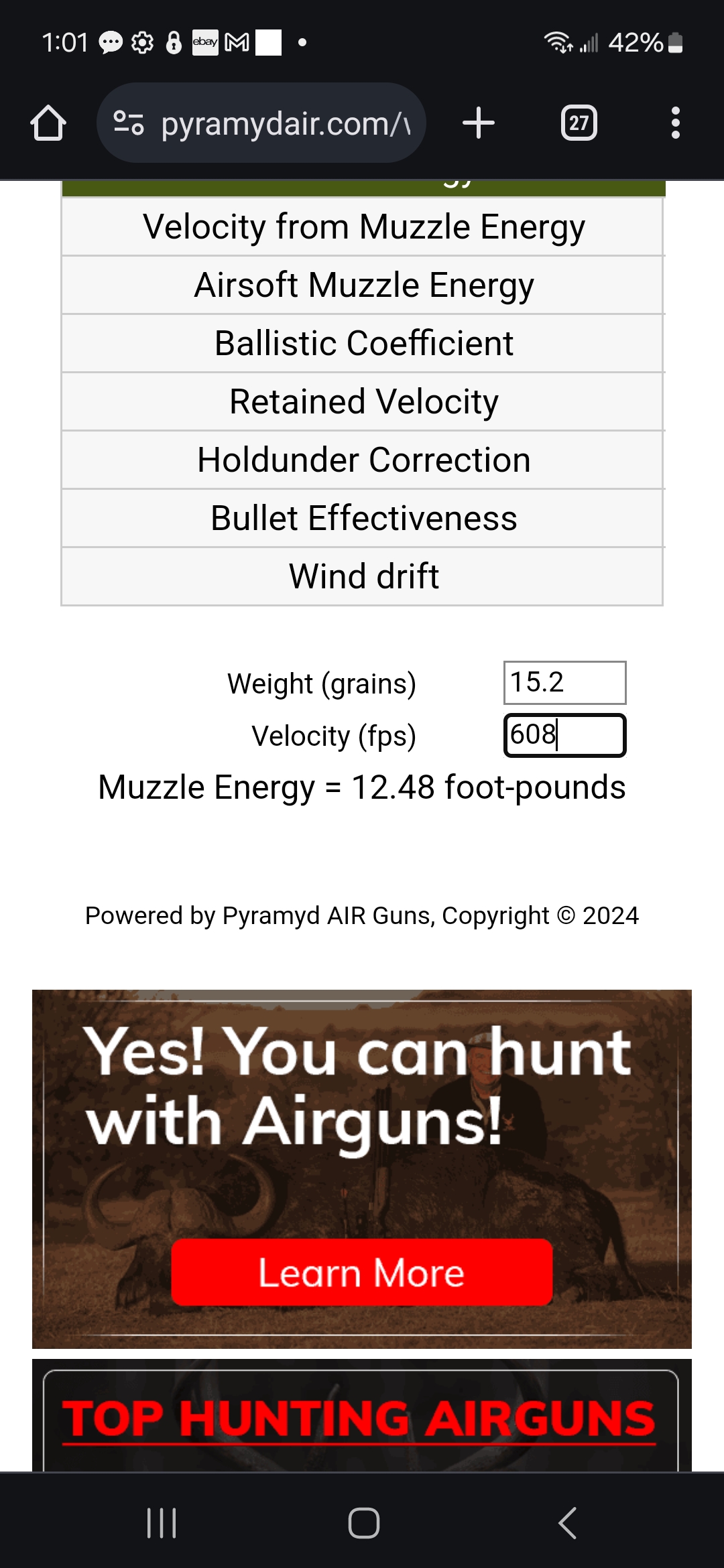

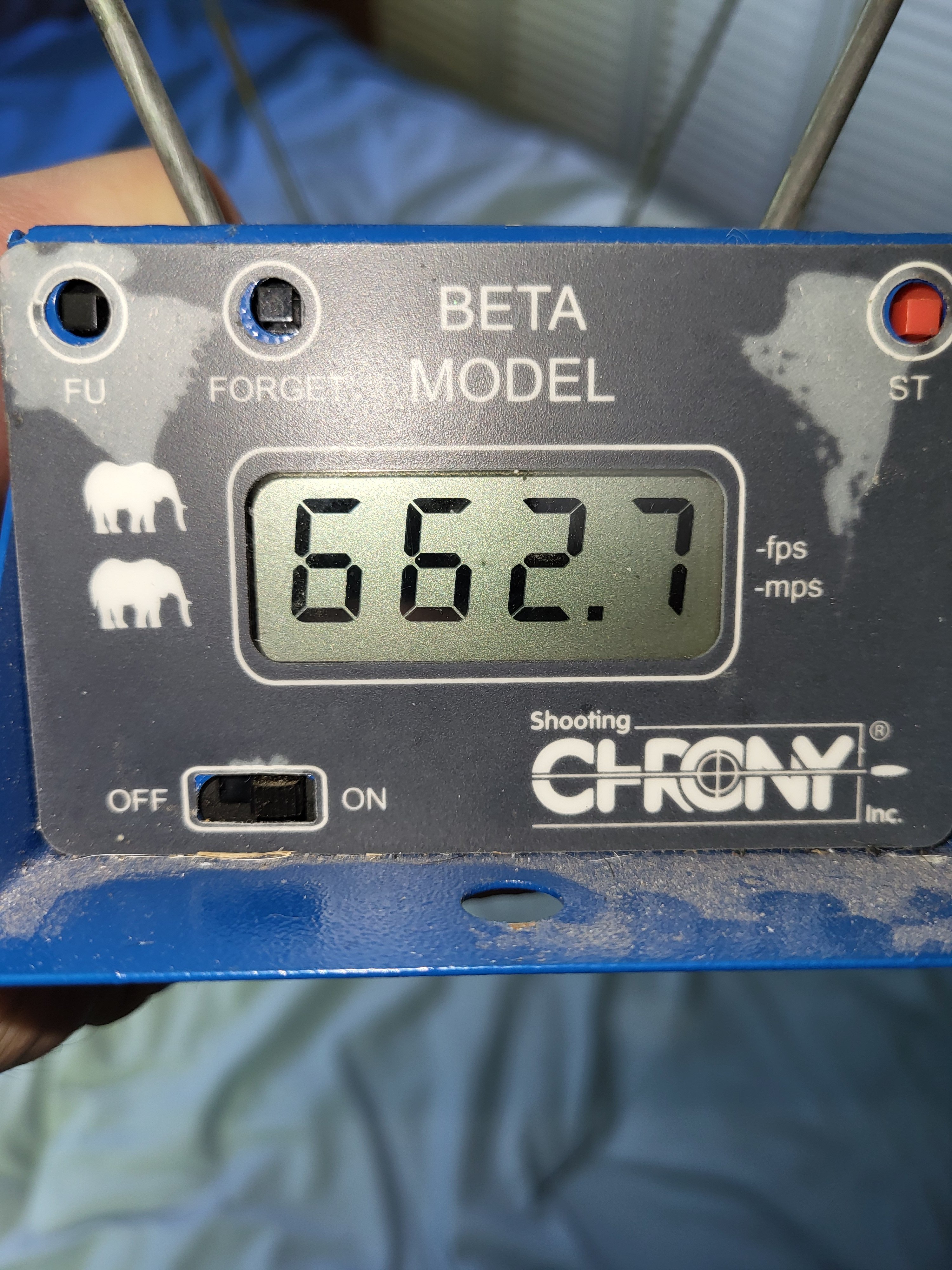

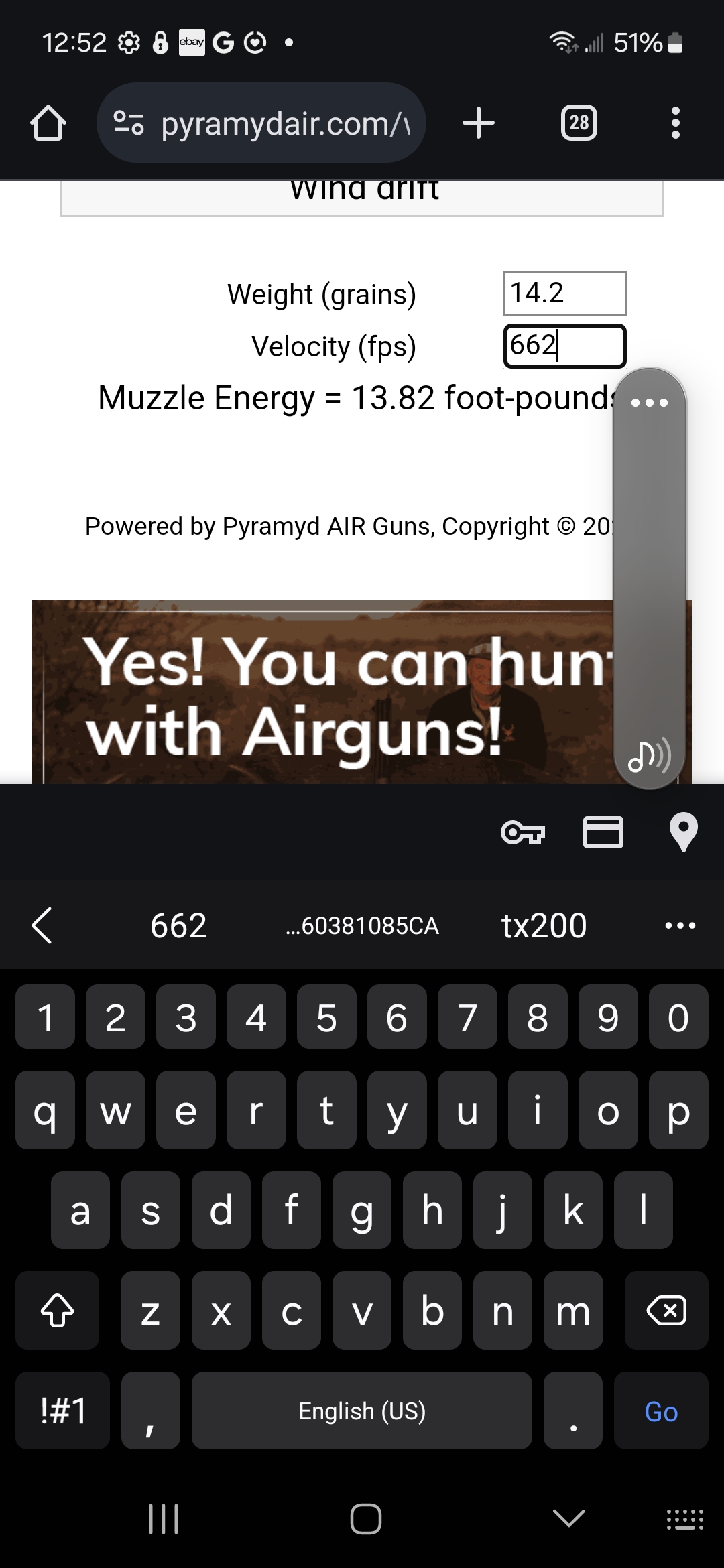

Did some chrono testing this morning. Using rws super h-points at 14.2 g.

Original fps 671

After cutting the spring 585

After the new spring guide 620 @ 12.12 fpe

Sear engagement has been flawless so far. Trigger pull is uneffected in any noticeable way.

Original fps 671

After cutting the spring 585

After the new spring guide 620 @ 12.12 fpe

Sear engagement has been flawless so far. Trigger pull is uneffected in any noticeable way.

Upvote 0

If you need a new parting tool this is well worth the $25 ...doesn't have the prestige of Robert sorby stuff or the refined metal selection but it does get the job done rather well. My wood lathe made more tobacco pipes than anything else.I too use my wood lathe for other purposes . nice job

Upvote 0

Now that's a Fine looking handful of Pipe!If you need a new parting tool this is well worth the $25 ...doesn't have the prestige of Robert sorby stuff or the refined metal selection but it does get the job done rather well. My wood lathe made more tobacco pipes than anything else.

View attachment 461522

Upvote 0

I have the lathe I played with as a kid. An old Beaver. Probably hasn’t been plugged in the last 30 years.

Spring guides needed, might be enough to give it some juice. Thanks Crow

Spring guides needed, might be enough to give it some juice. Thanks Crow

Upvote 0

Doesn't have to be anything fancy for spring guides. This was done on a jet mini, bolted to a work bench.I have the lathe I played with as a kid. An old Beaver. Probably hasn’t been plugged in the last 30 years.

Spring guides needed, might be enough to give it some juice. Thanks Crow

Upvote 0

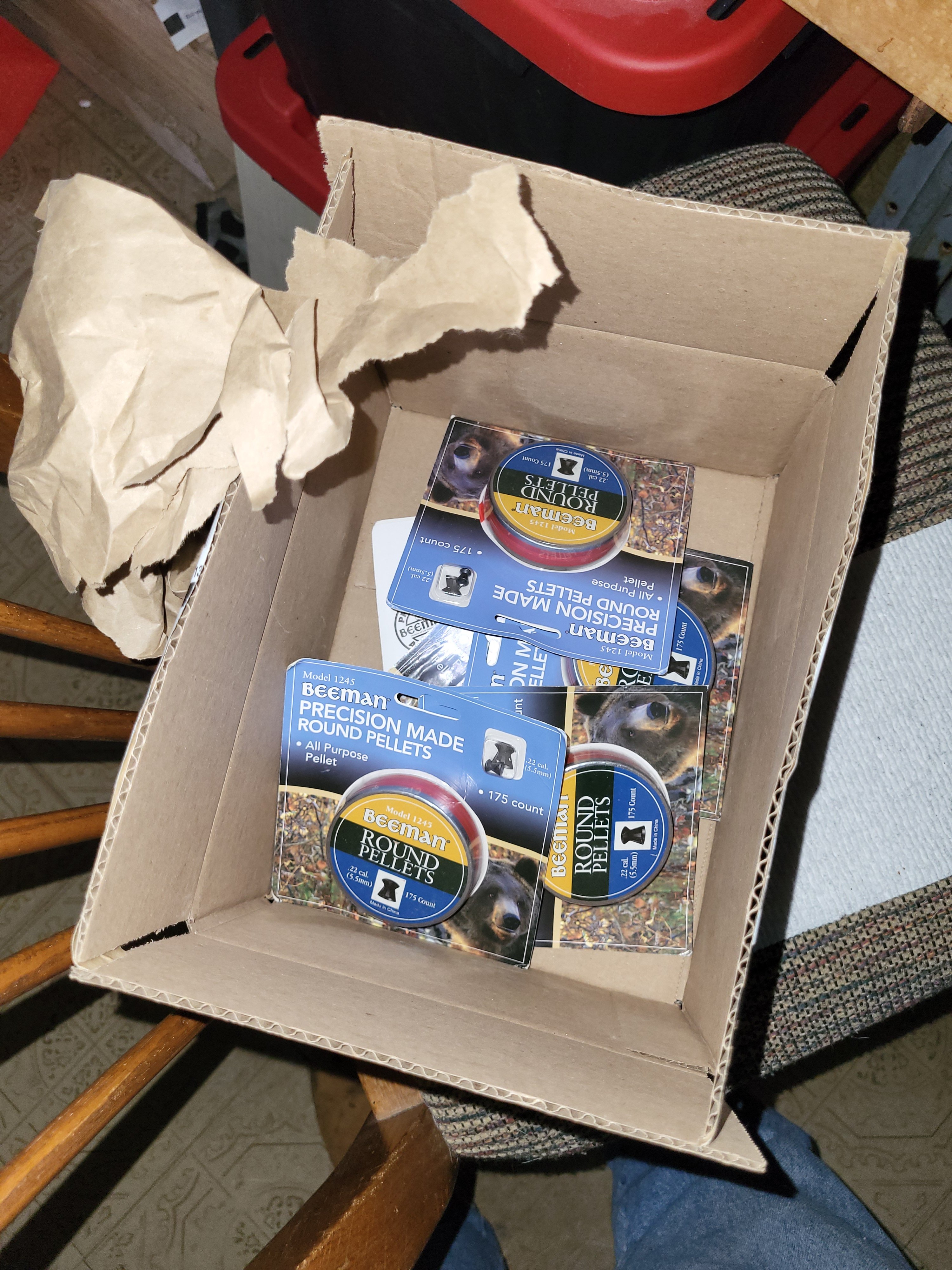

After all the mods, I cycled through pellet stash of .22. It now prefers beeman round nose 15.2 g. Prints decent groups at 20 yards when I do my parts.  just above British legal....'

just above British legal....'

Upvote 0

Typical amazon packaging, but blister packs survived well....1 shred of packing paper . Cures my problem of having a rifle that likes a pellet i only had half a tin left of. Back to tuning, tinkering and shooting!!!

Upvote 0

Last lathe expirement went well....so it's top hat time. Massive weight reduction, which I hope will smooth out some bounce during the recoil. Adding back in some spring compression again going from a total head thickness of .273 to .368 with the added washer.

Upvote 0

Shot cycle is feeling pretty good. Trigger feels a little heavier but not unmanageable. Yesterdays vertical stringing problem cancelled. I havent tested the rws hp ammo over the chronograph, but expect the numbers are going show close to a return to full power as they are a full g. Lighter than what i am currently shooting. Still got a few things to try another day.

Upvote 0

Rws super h points, coming in at 640 fps. Still a little detuned by comparison to the unmodified 671, but a much nicer gun to shoot atm

Upvote 0

More tinkering again today. Tore the rifle apart, I am not sure how many times this makes now. Spent a little time polishing, but not enlarging the transfer port. Made sure the power tube was nice and clean again.  changed the seal, and converted it to the weihrauch style creating a mild short stroke.

changed the seal, and converted it to the weihrauch style creating a mild short stroke.  added a shim in front of the tophat for again slightly more spring compression, and put it all back together. Now shooting Rws super hp...

added a shim in front of the tophat for again slightly more spring compression, and put it all back together. Now shooting Rws super hp... less than 9 fps shy of before I cut the spring. More tinkering to come....and the possibility for extreme mods once I figure it all out.

less than 9 fps shy of before I cut the spring. More tinkering to come....and the possibility for extreme mods once I figure it all out.

Upvote 0

I have fought with this barrel long enough. Super pellet picky, and the inside leaves a lot to be desired. Based on what I can feel polishing is not the fix for this. Has a rough entry where the rifling begins, followed by a rough patch with decent resistance. Then a loose section with very little resistance, another small tighter rough spot, and finishes with the last 6 in. Being loose again. I doubt the loose sections engage the rifling well. Visual inspection of the rifling, looks shallow all the way down. Time for extreme measures....

Upvote 0

A friend did a "shade tree mechanic" relining of a .22 RF barrel using the liner and drill bit from Brownells and epoxy. The results were very good. The drill bit was quite expensive.

I've been tempted to try this as I have had several Hatsan 135 .22 come new with extensive rust.

What rifle are you working on?

I've been tempted to try this as I have had several Hatsan 135 .22 come new with extensive rust.

What rifle are you working on?

Upvote 0

The rifle is a norica dream hunter in .22. No way to remove the barrel from the breech block. It's also an under lever which makes access from breech side quite limited with anything non flexible. The solution to my barrel issues is under way...we will see how it turns out. It's gonna be 1 of those pass or fail type mod attempts. Fingers crossed....A friend did a "shade tree mechanic" relining of a .22 RF barrel using the liner and drill bit from Brownells and epoxy. The results were very good. The drill bit was quite expensive.

I've been tempted to try this as I have had several Hatsan 135 .22 come new with extensive rust.

What rifle are you working on?

Upvote 0