So I was browsing eBay yesterday and ran across a seller for air rifle slugs. NONE of his offerings were custom. Also, he offered nothing in swaged ammo. Everything he was selling was cast ammo utilizing NOE bullet molds. Specifically the "Bob's Boat Tail" rounds. I noticed his pictured castings looked smooth and uniform, but they were EXTREMELY shiny and nearly platinum in color. Well, I'm no professional, but I own sever molds and have cast several thousand slugs in my day. All my slugs are small caliber (.25) multi cavity molds. And if any of you guys have cast small caliber slugs, you know how precise your equipment needs to be, and how temperamental the final product can be if everything isn't just right. I've played with different alloy blends for hardness by adding tin and antimony. The addition of these products will definitely help the overall look of the final product, but it also increases the hardness.

Like I said, this guys slugs look like platinum. So I cordially sent him an email and asked what the ratio was in his cast slugs as I was concerned that they might be too hard for my liking.

Now before I give you his response back, please tell me if I have overstepped in any way by asking this question...... I just want a consensus.

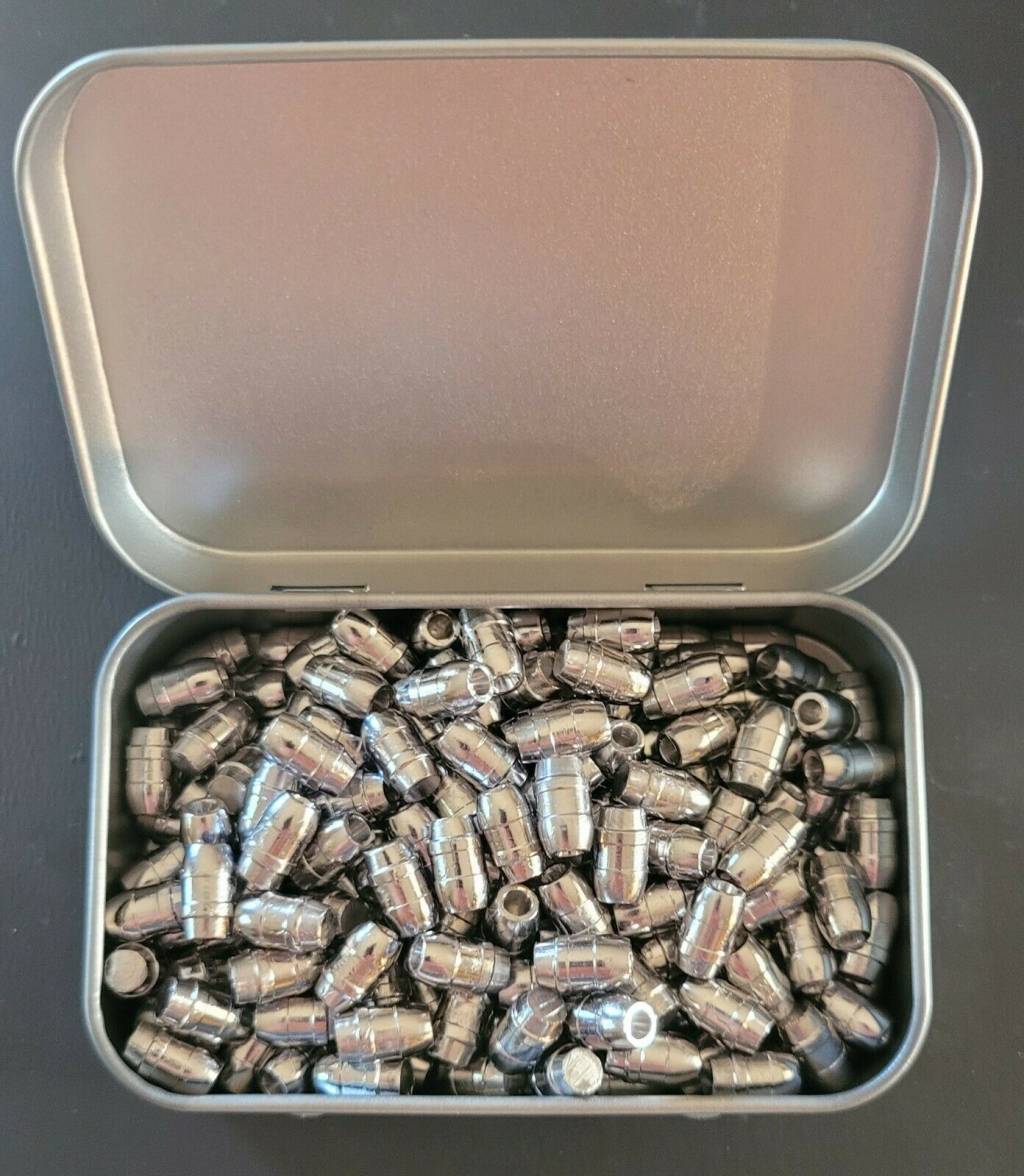

BTW- here are the slugs so you can see that they are indeed the Bob's Boat Tail slugs from NOE Bullet Molds. Also, notice the mirror, platinum finish.

Like I said, this guys slugs look like platinum. So I cordially sent him an email and asked what the ratio was in his cast slugs as I was concerned that they might be too hard for my liking.

Now before I give you his response back, please tell me if I have overstepped in any way by asking this question...... I just want a consensus.

BTW- here are the slugs so you can see that they are indeed the Bob's Boat Tail slugs from NOE Bullet Molds. Also, notice the mirror, platinum finish.