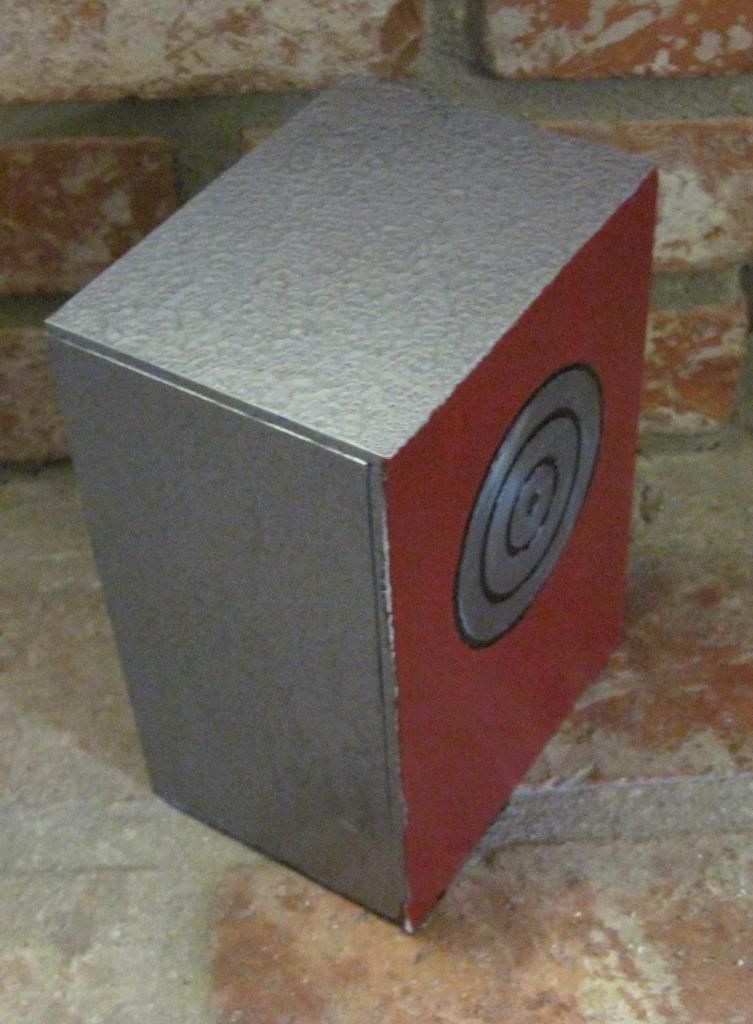

For you guys wanting to make your own targets but don't own a bunch of shop equipment you can get a free cad program online there are many that can export a DXF file you can send that file to a local shop that does water jet cutting and make all the targets you like using most any shape squirrel, rat, deer, hog etc. You can find the free files online with some searching. Search free clip art for the animals.

Mike

Mike

Upvote 0