But you dont have to call me Sir from now on.

Smeghead is OK ;-)

Let's see how many catchs that one.

I pounded a round ball through mine this afternoon and with my old eyes and a manual micrometer i get @ .733"

Anything smaller and you are assured blow by and reduced power.

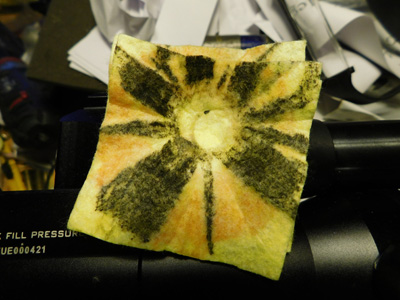

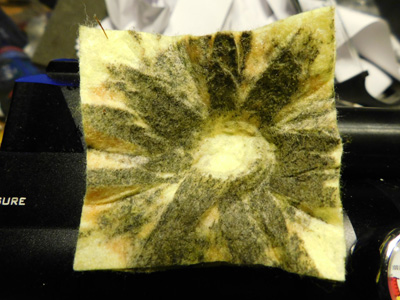

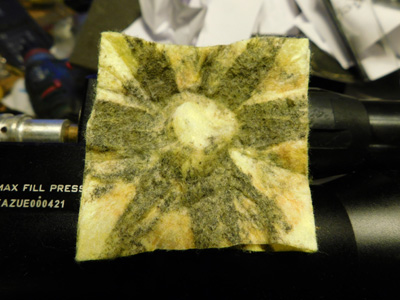

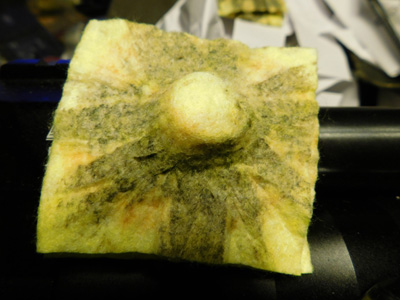

I put a lead ball well lubed down the bore and pulled a boresnake through.

Look at the crud these Auto Tranny Lube (Cant say Alphabet org "A7F") lubed pads got out!

Did they cover the innards with years old axle grease???

The first patches in sequence.

My bolt is so sloppy thet is cants and wont go into battery by itself, it needs a nudge.

Anyone else encountered this?

Now i need a scope and go shooting

Smeghead is OK ;-)

Let's see how many catchs that one.

I pounded a round ball through mine this afternoon and with my old eyes and a manual micrometer i get @ .733"

Anything smaller and you are assured blow by and reduced power.

I put a lead ball well lubed down the bore and pulled a boresnake through.

Look at the crud these Auto Tranny Lube (Cant say Alphabet org "A7F") lubed pads got out!

Did they cover the innards with years old axle grease???

The first patches in sequence.

My bolt is so sloppy thet is cants and wont go into battery by itself, it needs a nudge.

Anyone else encountered this?

Now i need a scope and go shooting