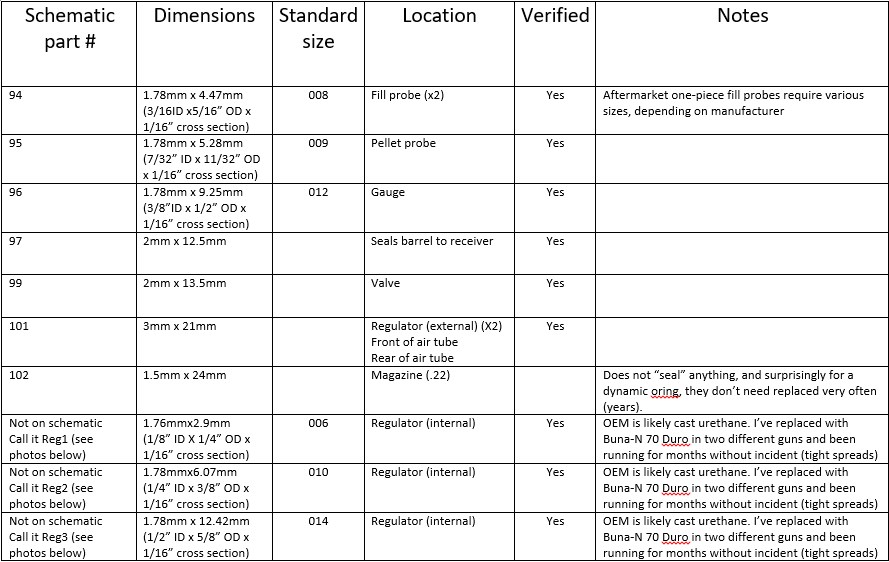

It seems I've replaced most of the orings in the Vet platform at one point or another, as I was inside the guns for one reason or another. The only ones that "needed" it were internal orings in a regulator that was acting up, and the oring under the gauge that became disformed when I pinched it swapping electronic gauges off and on the gun. The other's that I have replaced were just done because I was already inside the gun.

All that I have replaced have been done with Buna-N 70 Duro material/hardness. There's lots of debate about the best material and hardness, Please do your research when it comes to deciding what type to go with. (I'm not claiming that what I used was necessarily the best type).

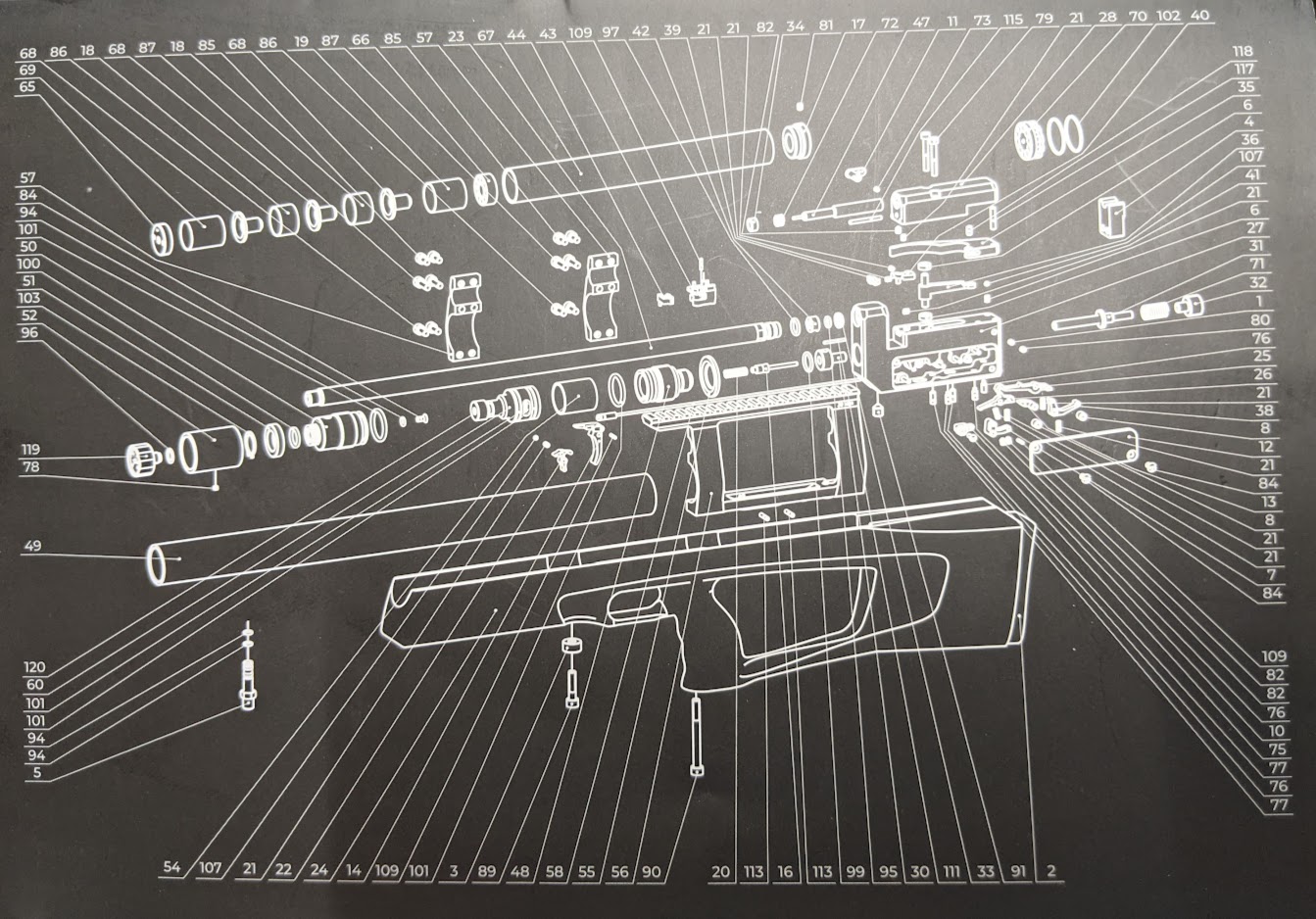

There may be another oring or two inside the air tube plug at the fill end. I've not needed to replace them and the schematic shows what may be another oring or two? (specifically part # 103. I think that is an oring that the fill port cover rides on as it is rotated to cover the fill probe hole, but don't hold me to that. Part # 100 may also be an oring. The numbers for those two are in the right sequence to be orings-to match Taipan's part numbering scheme. ).

I may go on with this project at some point by making a listing of all the schematic part numbers with a corresponding description (ie. #65 = shroud endcap).

Much thanks to @orion for his work on the Mutant here: https://www.airgunnation.com/threads/taipan-mutant-schematics-for-future-reference.488875/ Many of the Mutant and Veteran orings are shared and the information he included in that link helped immensely.

All that I have replaced have been done with Buna-N 70 Duro material/hardness. There's lots of debate about the best material and hardness, Please do your research when it comes to deciding what type to go with. (I'm not claiming that what I used was necessarily the best type).

There may be another oring or two inside the air tube plug at the fill end. I've not needed to replace them and the schematic shows what may be another oring or two? (specifically part # 103. I think that is an oring that the fill port cover rides on as it is rotated to cover the fill probe hole, but don't hold me to that. Part # 100 may also be an oring. The numbers for those two are in the right sequence to be orings-to match Taipan's part numbering scheme. ).

I may go on with this project at some point by making a listing of all the schematic part numbers with a corresponding description (ie. #65 = shroud endcap).

Much thanks to @orion for his work on the Mutant here: https://www.airgunnation.com/threads/taipan-mutant-schematics-for-future-reference.488875/ Many of the Mutant and Veteran orings are shared and the information he included in that link helped immensely.

Last edited: