You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Swagging Tips

- Thread starter AirSupply

- Start date

Genius!!!!

Thanks so much Tom, swaging that slug at the end of the video really showed me that the uneven cuts that I was getting should yield a good slug!

I wish I had a Home Depot close by to copy your cutter but I am happy cutting them by hand with what I got!

I am looking forward to more advice from you!!

Thanks again for sharing,

Lucas

Thanks so much Tom, swaging that slug at the end of the video really showed me that the uneven cuts that I was getting should yield a good slug!

I wish I had a Home Depot close by to copy your cutter but I am happy cutting them by hand with what I got!

I am looking forward to more advice from you!!

Thanks again for sharing,

Lucas

Upvote 0

Thanks Nick and Tom  What a great idea the shears are. Definitely going to look into that.

What a great idea the shears are. Definitely going to look into that.

Lucas the only other thing I might mention is maybe test some weights before you commit a whole lot of blanks.

One of the great things about swagging your own is you can swag a slug in a weight to suit your guns power output. Maybe do 50 in one weight try them for accuracy. Put them over the chronograph and decide if you want a little more or less weight.

Look forward to seeing your results

Lucas the only other thing I might mention is maybe test some weights before you commit a whole lot of blanks.

One of the great things about swagging your own is you can swag a slug in a weight to suit your guns power output. Maybe do 50 in one weight try them for accuracy. Put them over the chronograph and decide if you want a little more or less weight.

Look forward to seeing your results

Upvote 0

Guys, I am sorry to be such a pain, but I have a couple more questions. Say I have a gun that shoots well a 23 grain slug and another shoots well a 21 grain slug, is it very hard to readjust the dies in order to go from one weight to another? Do you waste a lot of slugs in order to get there or are there any settings within the die that might help you find the right weight faster?

Lucas

Lucas

Upvote 0

Lucas,

Once you do it, you'll get a "feel" for it. It doesn't take a lot of adjustment to bump it up, or down a grain or two. If both slugs are identical, other than the weight, it'll take about 6-8 tries to get it exact. You can't really mark the dies (maybe you can with the larger calibers and greater weight difference) but with a .177, 1/2 turn on the die for weight adjustment will give you 2-3 full grains difference. You wont waste a whole lot of lead once you get the hang of it. If lead is that expensive where you are, Corbins makes dies for the proper diameter , and you can reuse the "throwaway" lead.

Tom Holland

Field Target Tech

Once you do it, you'll get a "feel" for it. It doesn't take a lot of adjustment to bump it up, or down a grain or two. If both slugs are identical, other than the weight, it'll take about 6-8 tries to get it exact. You can't really mark the dies (maybe you can with the larger calibers and greater weight difference) but with a .177, 1/2 turn on the die for weight adjustment will give you 2-3 full grains difference. You wont waste a whole lot of lead once you get the hang of it. If lead is that expensive where you are, Corbins makes dies for the proper diameter , and you can reuse the "throwaway" lead.

Tom Holland

Field Target Tech

Upvote 0

As Tom said it won’t take many goes to get it right. You can just start a little on the heavy side and slowly wind the base down. You can keep re swagging the same slug down in weight till you get to your desired weight.

Upvote 0

Hi guys, I wanted to revive this post because after almost 4 months of waiting I finally got my press!!

I started swagging right away and everything looks fine so far! I'll have time this weekend to test them out of my gun!

I do have a couple of questions, I was hoping maybe someone can help me out!

I got one of those hollow ogive dies, I wanted to make some light 18grain slugs with it. I went through the 2 die process, ended up with 18 grain slugs, I decided to disect a few and then tried the regular 1 step die to get some more 18grain slugs, after cutting a few of them in half and comparing them, they were the same, what do you think went wrong? Should I shoot for 18 grains on the first part of the process and just close the gap with the second die without allowing any bleedoff?

Hope everyone has stayed safe,

Gracias y saludos,

Lucas

I started swagging right away and everything looks fine so far! I'll have time this weekend to test them out of my gun!

I do have a couple of questions, I was hoping maybe someone can help me out!

I got one of those hollow ogive dies, I wanted to make some light 18grain slugs with it. I went through the 2 die process, ended up with 18 grain slugs, I decided to disect a few and then tried the regular 1 step die to get some more 18grain slugs, after cutting a few of them in half and comparing them, they were the same, what do you think went wrong? Should I shoot for 18 grains on the first part of the process and just close the gap with the second die without allowing any bleedoff?

Hope everyone has stayed safe,

Gracias y saludos,

Lucas

Upvote 0

Hi guys thread revival again I have a Richard Corbin press with Dave Corbin dies ,I use pure new lead chopped to 1 foot lengths and kept in an air tight container, before swaging I clean each lead rod and then roll it buy hand on a granite slab in my loading bench ,cut the cores over the slug weight ,chop cores and then swage lube , the results I am getting are excellent, just one question do you was and relive your slugs after swaging ,I tend to get very slight lead bleed on the back of the slug ,i comes off just with a slight touch with your finger .

Upvote 0

I use my heated Ultrasonic tank....

Some soapy water....

This does the trick... it removes in trailing or swarf.

Stuart

Some soapy water....

This does the trick... it removes in trailing or swarf.

Stuart

Upvote 0

Hello I didn’t know you were on here , I am shooting the slugs through my Raw hm1000x and my Fx impact ,

Would love a bit more oomph out of the raw , 27 grain are doing just over 900 fps , on 150 reg ,any pointers

Would love a bit more oomph out of the raw , 27 grain are doing just over 900 fps , on 150 reg ,any pointers

Upvote 0

Well the to get the job done... is air flow...

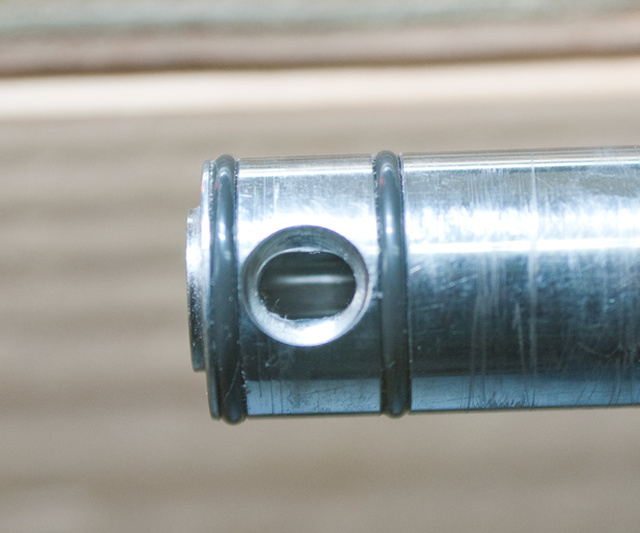

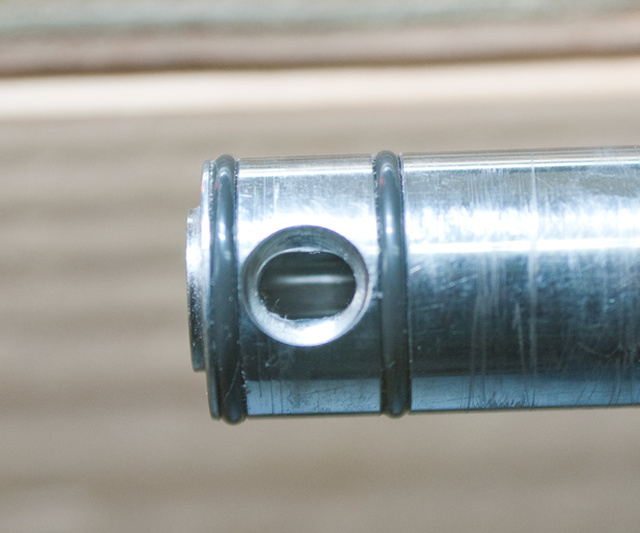

So the through-port in the barrel may be the restriction.....

Or maybe the Valve-body and Valve-stem.....

Good Luck

Stuart

So the through-port in the barrel may be the restriction.....

Or maybe the Valve-body and Valve-stem.....

Good Luck

Stuart

Upvote 0

I have taken the original valve out and fitted a peek unit ,it has a smaller port is very consistent and fps is about the same as the original .

Upvote 0

Wow, the company I just retired from was handing those out to get rid of them one day. I don’t know if somebody determined there were too many in stock or there was a burr on them or what. But functionally they were fine. I got about ten of them and handed them out to everyone I knew that could use one.Lucas,

Here you go!!!

Tom Holland

Field Target Tech

Upvote 0