You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Swagging slugs

- Thread starter warchlaq

- Start date

i'd like to know more info on your findings and how you managed to turn these on a lathe. i got a southbend 10k and would love to be able to make my own kit as well.

Upvote 0

Upvote 0

i'd like to know more info on your findings and how you managed to turn these on a lathe. i got a southbend 10k and would love to be able to make my own kit as well.

If it were me and all I had was a manual lathe, I would machine a D bit reamer out of tool steel such as A2 to the desired slug profile (if it doesn't have drive bands otherwise undersize the tool diameter and use your X axis to enlarge the die bole hole as needed), heat treat and sharpen with a stone for your cutting tool. I would then machine the bore hole hole in the steel die blank with an undersized drill and use a small enough endmill as a boring bar to true out the drilled hole but leave enough stock for the next opp. Then use the reamer to finalize the shape of the die. Don't forget the liberal use of a quality cutting oil. Lastly machine your swaging punches, heat treat and polish. You are going to want to have a set of gauge pins to inspect your bore.

Upvote 0

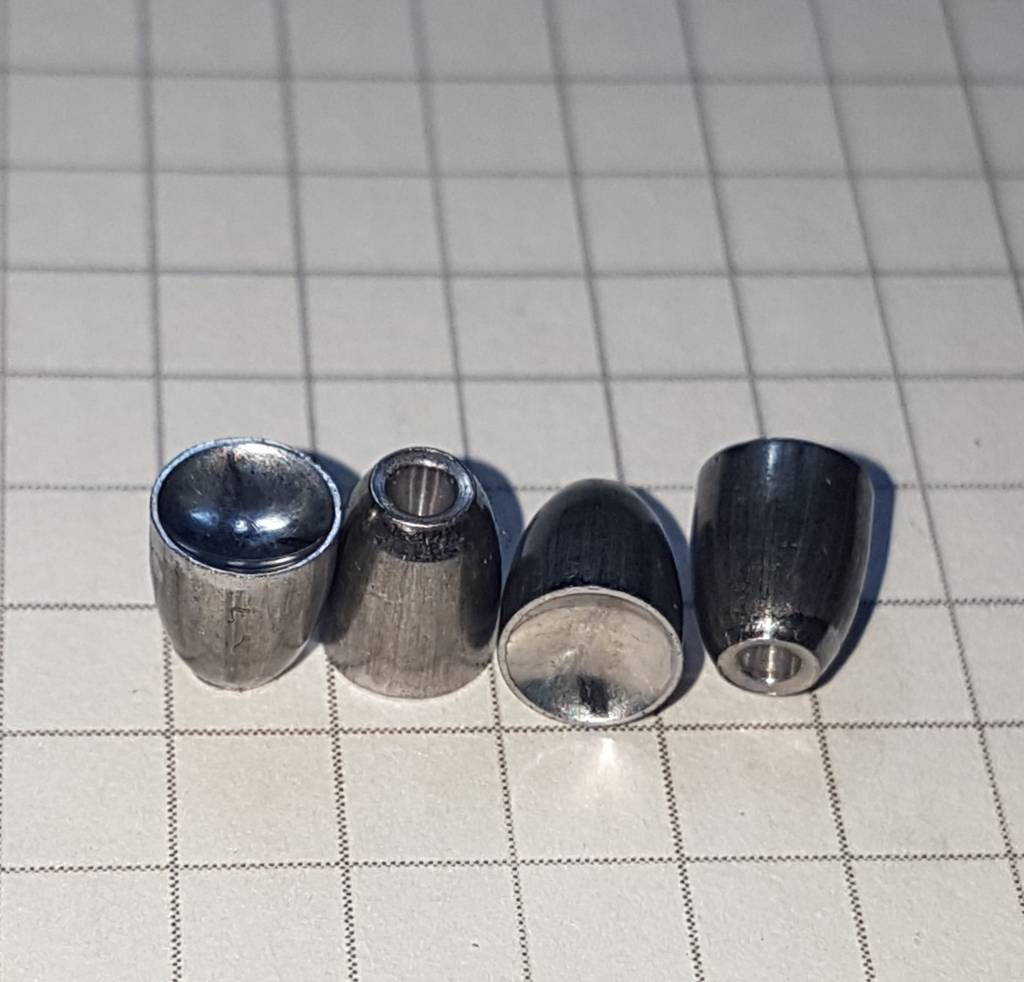

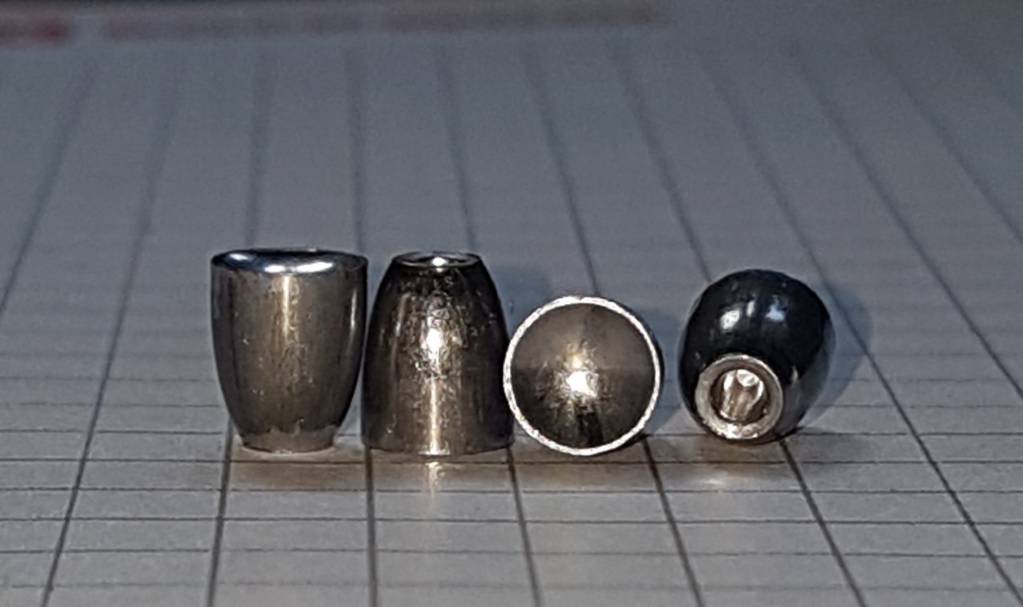

New in the family, especially for my rapid, .22 hp slug 36.5 grain. For comparison, JSB KO 25.4 grain.

Upvote 0

Great job my friend, being a retired tool & die maker it is great to see guys as you to have the fortitude to do the research & go after it. Most people do not realize the time &

work you put into your accomplishment, but I do. I applaud !

Fly

work you put into your accomplishment, but I do. I applaud !

Fly

Upvote 0

1.27grams (19.6 grain). With a different HP pin, you can go down to the weight of jsb jumbo heavy.

And 1.35 grams (20.8 grain)

And 1.35 grams (20.8 grain)

Upvote 0

That’s awesome, good jobA month ago, maybe a little longer, I bought myself a small lathe and am having fun.

Upvote 0