Everyone makes slugs, and I do  My prototype, made from what I found in the garage, from waste, but it works

My prototype, made from what I found in the garage, from waste, but it works

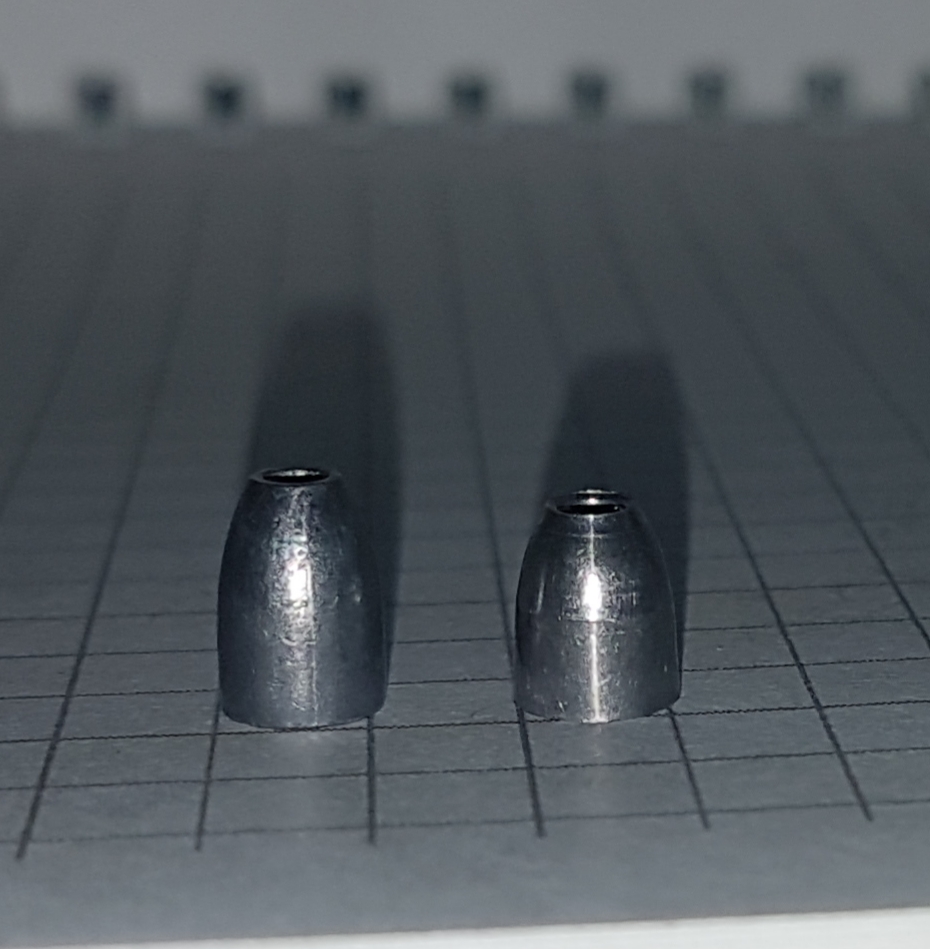

Left slug is JSB KO, right my 18grain slug.

18grain, same weight, different length, the length of the slugs can be adjusted by changing the HP forming pin.

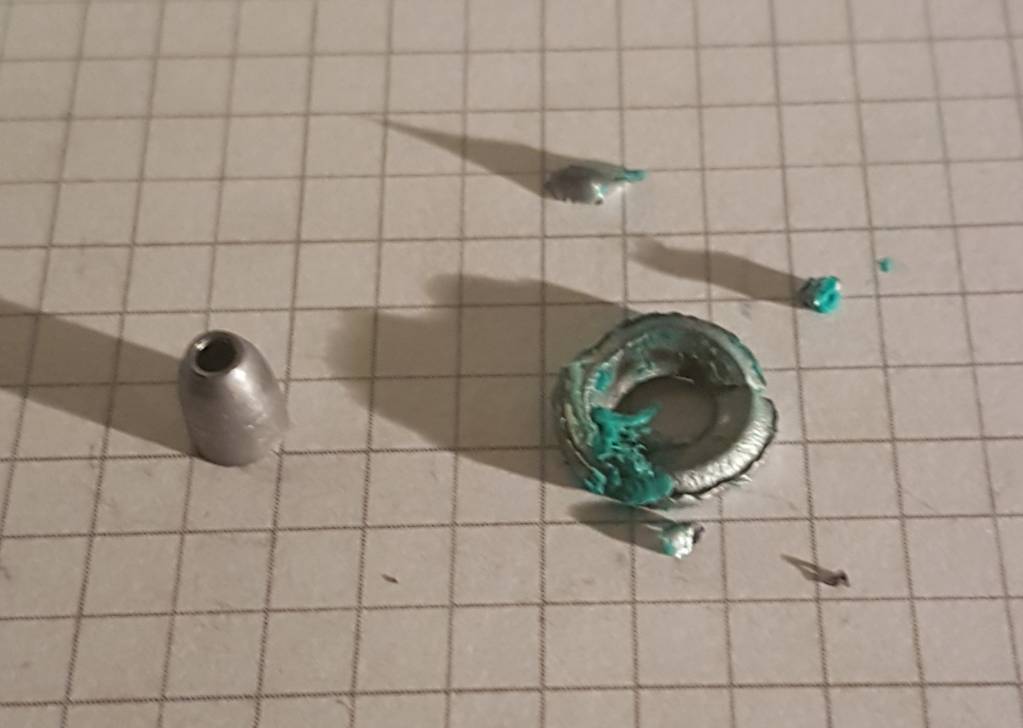

Plasticine expansion test, 18grain v0 285m/s

Plasticine expansion test, 18grain v0 285m/s

At the moment, I use JSB jumbo heavy pellets as a material, it is the most convenient for me.

Left slug is JSB KO, right my 18grain slug.

18grain, same weight, different length, the length of the slugs can be adjusted by changing the HP forming pin.

At the moment, I use JSB jumbo heavy pellets as a material, it is the most convenient for me.