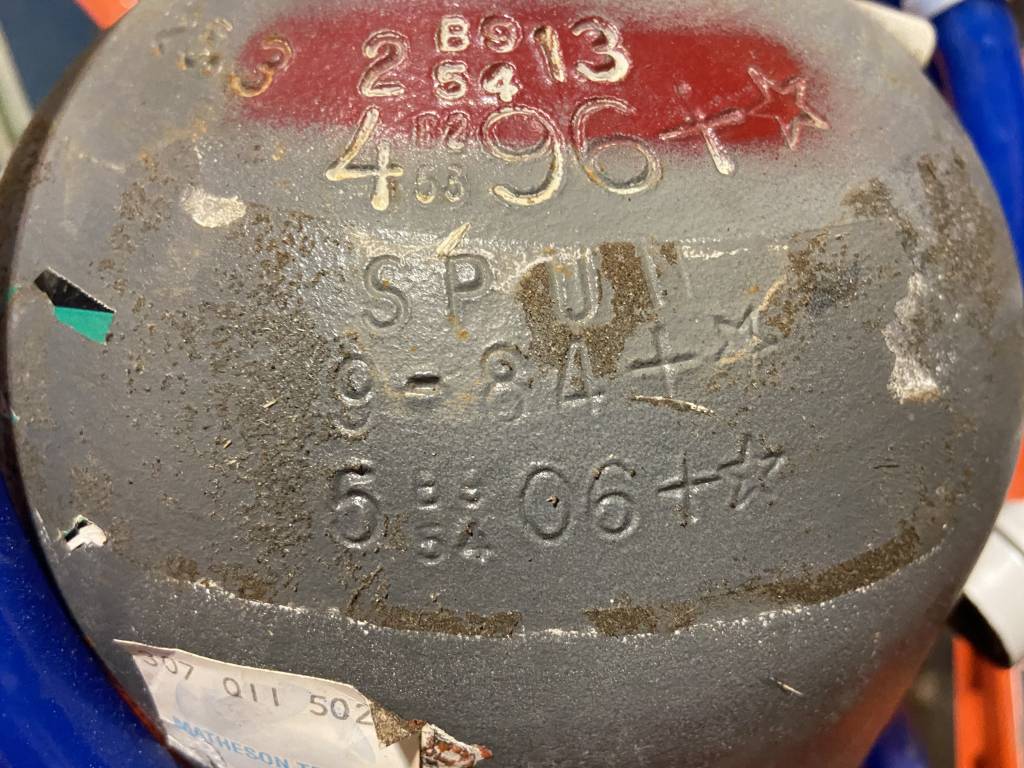

As the title says, I have a 10lb CO2 bottle - Steel. The dimensions are 20.75" Tall x 7" wide. I've been looking into removing the valve and replacing it with this:

https://www.amazon.com/IORMAN-4500psi-Paintball-Regulator-Fittings/dp/B0793PQMT1/ref=sr_1_1?crid=3PA8MG4ZYJGIN&dchild=1&keywords=pcp+regulator+4500psi&qid=1616684899&sprefix=pcp+regulat%2Caps%2C163&sr=8-1

Assuming the threads are the correct size, can I simply take it to my local dive shop and have them fill it? Is there more to this that I'm missing? I need to learn here...

https://www.amazon.com/IORMAN-4500psi-Paintball-Regulator-Fittings/dp/B0793PQMT1/ref=sr_1_1?crid=3PA8MG4ZYJGIN&dchild=1&keywords=pcp+regulator+4500psi&qid=1616684899&sprefix=pcp+regulat%2Caps%2C163&sr=8-1

Assuming the threads are the correct size, can I simply take it to my local dive shop and have them fill it? Is there more to this that I'm missing? I need to learn here...