The Standard Range

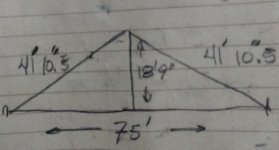

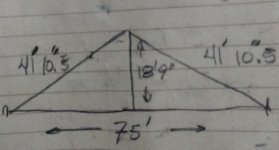

The test range is laid out like this diagram:

The diagram is as I drew it into my notebook. The bench is on the left side of the diagram and the backstop is on the right side. The microphone is located at the top between the two triangles. It is placed on a concrete slab (a brick would do as well) which elevates it about 3 inches above the grass. There are two microphones on the phone I am using so I made two wind mufflers by printing gyroid infill cubes which fit on the ends of the camera. These perform well. Today there was gusty wind blowing with peak speeds around 20 mph. I don't hear any wind noise in the audio so they must be working.

I chose a 25 yard distance because I can easily duplicate the range in nearly any grassy space in just a few minutes with a 50 foot tape and some stakes. I chose to put the camera close to the ground because it was easier than making a stand and the grass tends to hold down echos coming off the ground. The size of the test range will help to ensure that the recording device does not experience "clipping" by being overloaded with the noise we are trying to measure. The microphone is located equidistant from the bench and the backstop because that simplifies the calculations when solving for muzzle velocity and when comparing the sound of the shot to the sound of the pellet striking the backstop (or whatever I put at that spot).

This is probably the final configuration of this range as it is nearly perfect for my purposes.

The Standard Moderator

Today I tested a "Standard 17" moderator design. I call this moderator the "Standard" because it is the design I build whenever I want to test some new theory. It is standardized and I am using the same test rifles with the same power levels, tunes, and projectiles in all my tests. I do this in the hope that I can achieve reproducible results from one day to the next. That will allow me to save data between tests and compare them later. In the end that will mean less repetition in the data collection effort.

The specifications of this moderator:

DIameter: ~1.2 inches; 30mm

Length: ~5 inches; 125mm

Weight: 59 grams; 2.00 oz.

Thread: EZTap 1/2 x 20 UNF

CONSTRUCTION DETAILS REMOVED IN KEEPING WITH THE CONCERNS OF MANAGEMENT

When I test I record the test session with my phone and then analyze the test in Audacity software.

I recorded the entire session and have removed all of the dead air. The remaining file contains all of the data which interests us for this test. Here it is:

Here is the comparison of the audio without and with the moderator.

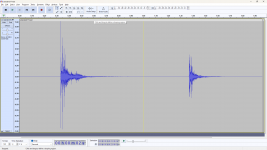

Here is the Audacity graphic of the two shots which are being repeated in the above clip.

Analysis of these two shots shows that the moderator reduces the report of the bare rifle by 3.6 dB.

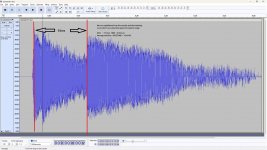

Using the audio data from the last three shots heard in the top audio clip we can calculate the average velocity over the range for that rifle and pellet. This image shows the start and end times for the shot and impact noises for one of those shots. Strelok confirms this corresponds to a muzzle velocity of about 860 fps which equates to about 18 foot pounds.

This is a nice little moderator. It was inspired by a desire to improve on the Weirauch/Huggette "hair curler" design.

I'm happy with the design.

The test range is laid out like this diagram:

The diagram is as I drew it into my notebook. The bench is on the left side of the diagram and the backstop is on the right side. The microphone is located at the top between the two triangles. It is placed on a concrete slab (a brick would do as well) which elevates it about 3 inches above the grass. There are two microphones on the phone I am using so I made two wind mufflers by printing gyroid infill cubes which fit on the ends of the camera. These perform well. Today there was gusty wind blowing with peak speeds around 20 mph. I don't hear any wind noise in the audio so they must be working.

I chose a 25 yard distance because I can easily duplicate the range in nearly any grassy space in just a few minutes with a 50 foot tape and some stakes. I chose to put the camera close to the ground because it was easier than making a stand and the grass tends to hold down echos coming off the ground. The size of the test range will help to ensure that the recording device does not experience "clipping" by being overloaded with the noise we are trying to measure. The microphone is located equidistant from the bench and the backstop because that simplifies the calculations when solving for muzzle velocity and when comparing the sound of the shot to the sound of the pellet striking the backstop (or whatever I put at that spot).

This is probably the final configuration of this range as it is nearly perfect for my purposes.

The Standard Moderator

Today I tested a "Standard 17" moderator design. I call this moderator the "Standard" because it is the design I build whenever I want to test some new theory. It is standardized and I am using the same test rifles with the same power levels, tunes, and projectiles in all my tests. I do this in the hope that I can achieve reproducible results from one day to the next. That will allow me to save data between tests and compare them later. In the end that will mean less repetition in the data collection effort.

The specifications of this moderator:

DIameter: ~1.2 inches; 30mm

Length: ~5 inches; 125mm

Weight: 59 grams; 2.00 oz.

Thread: EZTap 1/2 x 20 UNF

CONSTRUCTION DETAILS REMOVED IN KEEPING WITH THE CONCERNS OF MANAGEMENT

When I test I record the test session with my phone and then analyze the test in Audacity software.

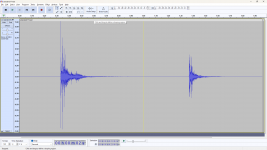

I recorded the entire session and have removed all of the dead air. The remaining file contains all of the data which interests us for this test. Here it is:

Here is the comparison of the audio without and with the moderator.

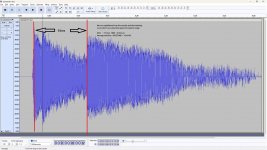

Here is the Audacity graphic of the two shots which are being repeated in the above clip.

Analysis of these two shots shows that the moderator reduces the report of the bare rifle by 3.6 dB.

Using the audio data from the last three shots heard in the top audio clip we can calculate the average velocity over the range for that rifle and pellet. This image shows the start and end times for the shot and impact noises for one of those shots. Strelok confirms this corresponds to a muzzle velocity of about 860 fps which equates to about 18 foot pounds.

This is a nice little moderator. It was inspired by a desire to improve on the Weirauch/Huggette "hair curler" design.

I'm happy with the design.

Last edited: